Unveiling the Secrets: How Waterproof Distribution Boxes Protect Your Electrical Systems in Extreme Environments

In today's rapidly evolving technological landscape, the demand for reliable electrical systems has never been greater, especially in extreme environments. Waterproof Distribution Boxes have emerged as critical components in safeguarding electrical elements from the harsh conditions that can compromise performance and safety. As expert in the field, Dr. Emily Chen, a leading engineer at the National Electrical Safety Institute, emphasizes, "The integrity of electrical systems in adverse conditions hinges on the superior protection offered by Waterproof Distribution Boxes."

These specialized enclosures are engineered to withstand moisture, dust, and other environmental factors that could lead to electrical failures. By sealing vital connections and components, Waterproof Distribution Boxes not only enhance the longevity of electrical systems but also reduce the risk of hazardous incidents, ensuring safety for both equipment and personnel. As industries shift towards more sustainable practices, understanding the significance of these protective measures becomes increasingly crucial.

In this article, we will delve into the various features and benefits of Waterproof Distribution Boxes, highlighting their role in preserving the function and reliability of electrical systems across diverse industries. From construction sites to outdoor installations, we will explore how these protective solutions stand up to the challenges posed by extreme environments, ultimately unveiling the secrets behind their effectiveness.

Understanding Waterproof Distribution Boxes and Their Importance in Harsh Conditions

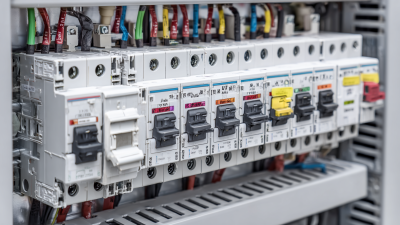

Waterproof distribution boxes are essential components that safeguard electrical systems in extreme environments. These boxes provide an airtight seal, effectively preventing moisture, dust, and other contaminants from infiltrating the electrical components. In harsh conditions—such as high humidity, heavy rain, or excessive dust—traditional electrical enclosures might fail, leading to costly malfunctions or potentially hazardous situations. Understanding the design and functionality of waterproof distribution boxes can help in selecting the right protection for sensitive electrical equipment.

The significance of waterproof distribution boxes becomes even more apparent in industries like construction, marine, and agriculture, where equipment often faces unpredictable weather and environmental challenges. These boxes are built with robust materials that not only resist corrosion but also withstand temperature fluctuations. By utilizing waterproof distribution boxes, businesses can ensure the longevity and reliability of their electrical systems, minimizing downtime and maintenance costs. Thus, acknowledging their importance is crucial for anyone looking to enhance the durability and performance of electrical installations in extreme environments.

Impact of Waterproof Distribution Boxes in Extreme Environments

Key Features of Waterproof Distribution Boxes for Electrical System Protection

Waterproof distribution boxes are essential for safeguarding electrical systems, particularly in extreme environments such as construction sites, marine applications, and outdoor industrial operations. These boxes are engineered with protective features that ensure longevity and reliability. Key characteristics include their IP (Ingress Protection) rating, which indicates resistance to dust and water. A recent industry report highlights that systems housed in waterproof boxes experience up to 50% fewer failures in harsh conditions compared to unprotected setups.

In addition to their robust construction, waterproof distribution boxes often come with UV resistance and corrosion-proof materials, making them suitable for prolonged exposure to the elements. Utilizing such high-grade materials can extend the lifespan of electrical systems significantly; some manufacturers claim an increase in durability by up to 30%. Additionally, these boxes facilitate efficient heat dissipation, which is crucial for preventing overheating in electrical components.

**Tips:** When selecting a waterproof distribution box, ensure it meets at least an IP65 rating for reliable protection against dust and water jets. Regular maintenance checks are imperative; inspect seals and gaskets every few months to ensure they remain intact. Always consider the environmental conditions to choose a box that offers the best resistance, tailoring your choice to factors such as humidity and temperature extremes.

Impact of Environmental Conditions on Electrical System Performance and Reliability

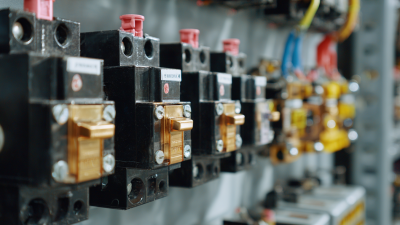

Environmental conditions play a crucial role in the performance and reliability of electrical systems. Factors such as humidity, temperature fluctuations, and exposure to corrosive substances can severely impact the operational efficiency of electrical components. For instance, high humidity levels can lead to moisture intrusion, resulting in circuit failures and short circuits. Similarly, extreme temperatures can cause materials to expand or contract, leading to physical stress on connection points and components.

Waterproof distribution boxes are specifically designed to protect electrical systems from these adverse environmental effects. By forming a robust barrier against moisture and external contaminants, these boxes ensure that vital electrical connections remain intact and operational. Furthermore, they are often made from materials resistant to corrosion and UV degradation, extending the lifespan of the electrical systems housed within. In extreme environments, such as coastal regions or industrial sites, the value of these protective measures becomes even more evident, as they significantly reduce the risk of downtime and maintenance costs associated with environmental damage.

Industry Standards and Certifications for Waterproof Distribution Boxes Explained

When it comes to safeguarding electrical systems in extreme environments, understanding the industry standards and certifications for waterproof distribution boxes is paramount. These certifications, such as the IP (Ingress Protection) rating, indicate the level of protection against dust and water ingress. For instance, an IP67 rating signifies that the device is dust-tight and can withstand immersion in water up to 1 meter for 30 minutes, making it suitable for harsh conditions like marine and industrial applications.

In addition to IP ratings, various certifications from organizations such as Underwriters Laboratories (UL) and the International Electrotechnical Commission (IEC) ensure that waterproof distribution boxes meet specific safety and performance criteria. Compliance with these standards assures users that the products have undergone rigorous testing for durability and insulation, minimizing the risks of electrical failures. Understanding these certifications not only helps in selecting the right products but also provides peace of mind that electrical systems will remain operational and safe, even in the toughest environments.

Selecting the Right Waterproof Distribution Box for Your Specific Application Needs

When it comes to safeguarding electrical systems in extreme environments, selecting the right waterproof distribution box is crucial. The first step in this process is to assess the specific application requirements. Different environments possess unique challenges, from exposure to water and dust to extreme temperatures and corrosive elements. Understanding these factors allows for the selection of a distribution box that meets both durability and operational efficiency.

Another critical aspect is the material used in the construction of the waterproof distribution box. Options like polycarbonate or metal enclosures offer varying levels of protection and durability. Consider the IP (Ingress Protection) rating, which informs users about the level of dust and water resistance. For instance, an IP67-rated box is suitable for submersion in water, while a lower rating may suffice for environments with occasional moisture exposure. Additionally, ensure that the box provides adequate space for wiring and component installation, allowing for ease of maintenance and upgrades as your electrical needs evolve.

Home

About Us

Products

Terminal Power Distribution Electric

AC Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

MCB Accessories

Main Switch

RCBO RCCB

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

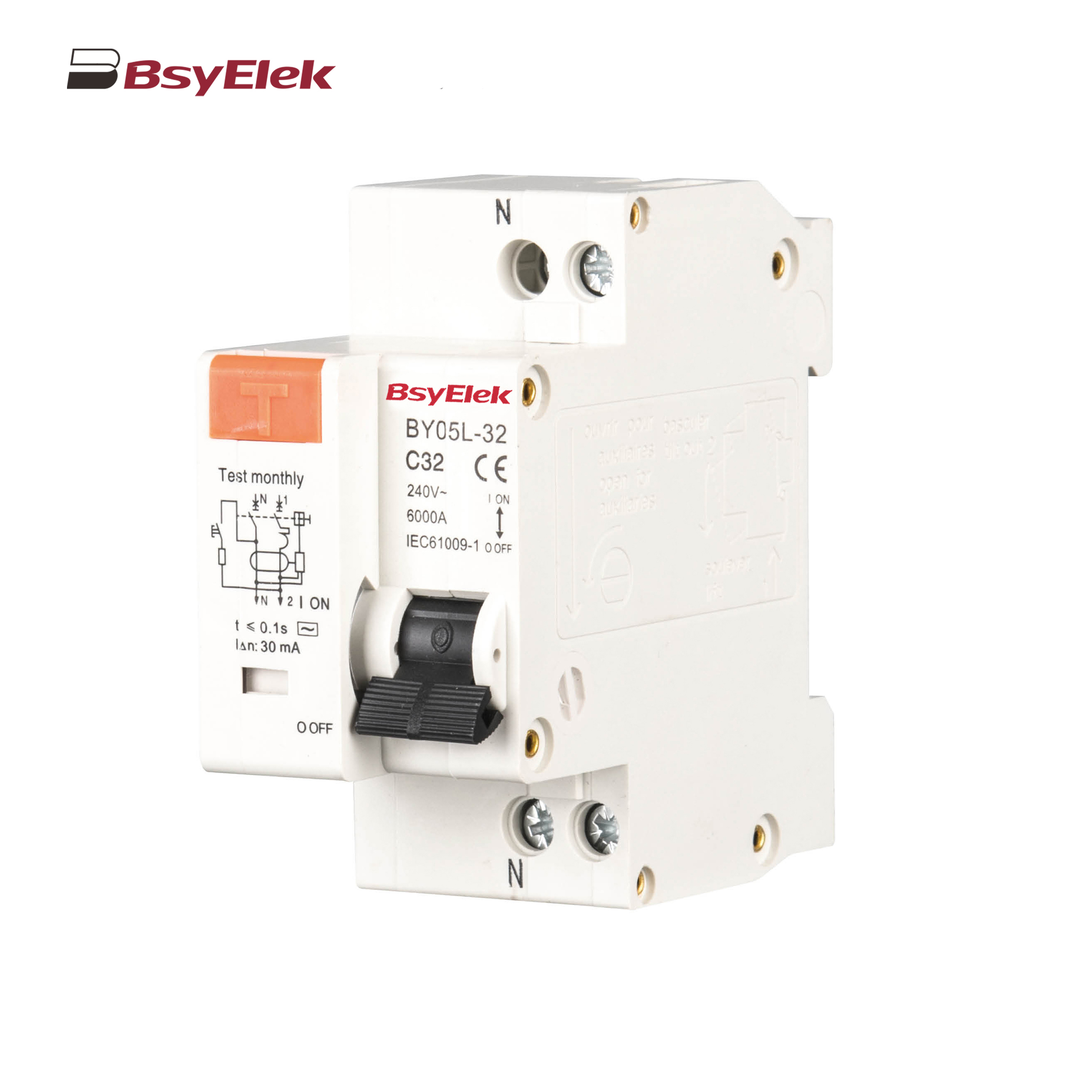

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

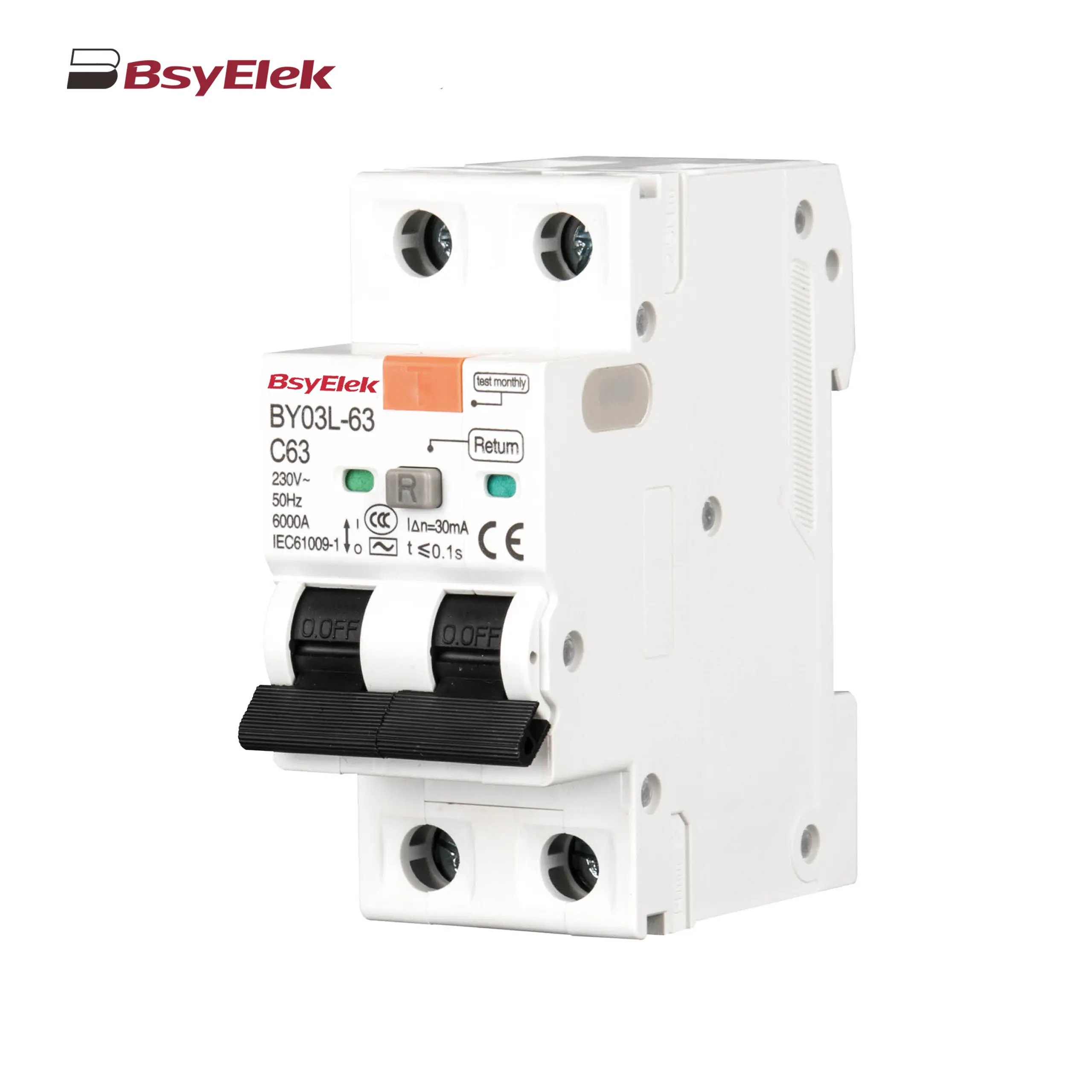

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

Resettable Overvoltage and Undervoltage Protector

AC Contactor

AC Surge Protective Device

Changeover Switch

Photovoltaic System Protection

DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

RCD

DC Surge Protective Device

DC Fuse

PV Isolator Switch

PV Connector

Cable Gland

PV Cable

PV Knife Switch

DC Molded Case Circuit Breaker

Industrial Power Distribution Electric

Distribution Box

Air Conditioning System

Definite Purpose Magnetic Contactor

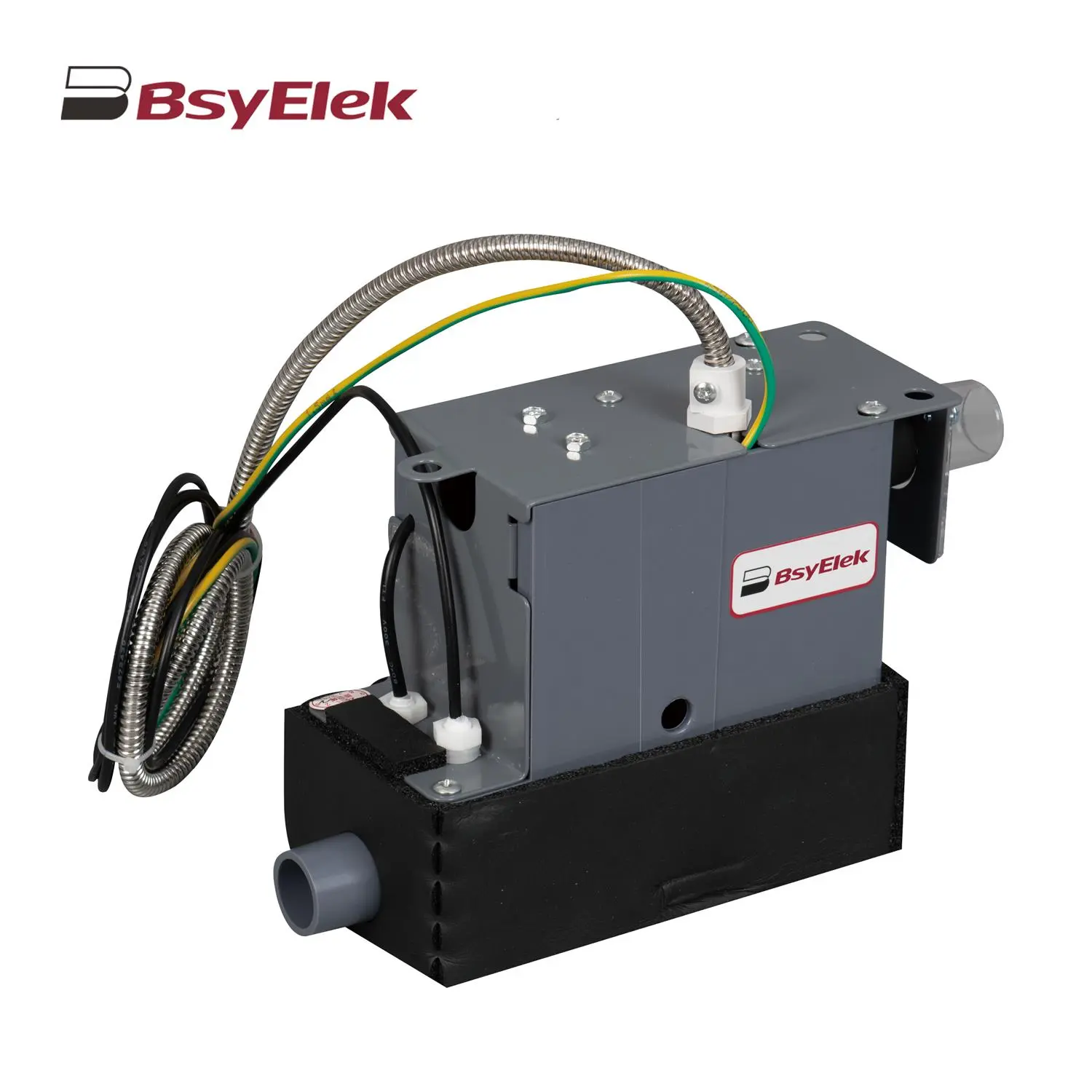

Condensate Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-24B/40B 10M Split Type Drainage Pump

BY-24B/40B 10M Split Type Drainage Pump

BY-100L 2M Drainage Pump of Air Conditioner

BY-100L 2M Drainage Pump of Air Conditioner

BY-360L 6M Large Displacement Drainage Pump

BY-360L 6M Large Displacement Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

News

Top Blog

Company News

Industry Dynamics

What is a miniature circuit breaker (MCB)?

PG Series Waterproof Cable Glands with Washer for Harsh Environments

LWSF-125 125A Manual Changeover Switch ensures reliable power transfer

BYX2 AC contactor series: reliable power control for modern electrical systems

High-performance 1000V DC fuse holder optimizes solar photovoltaic system protection

BY07L-63 Residual Current Circuit Breaker Ensures Global Electrical Safety

BYQ5 ATS Isolation Dual Power Automatic Transfer Switch

BY19G 63A Manual Changeover Switch: Features and Benefits

Support

Blog

Contact Us

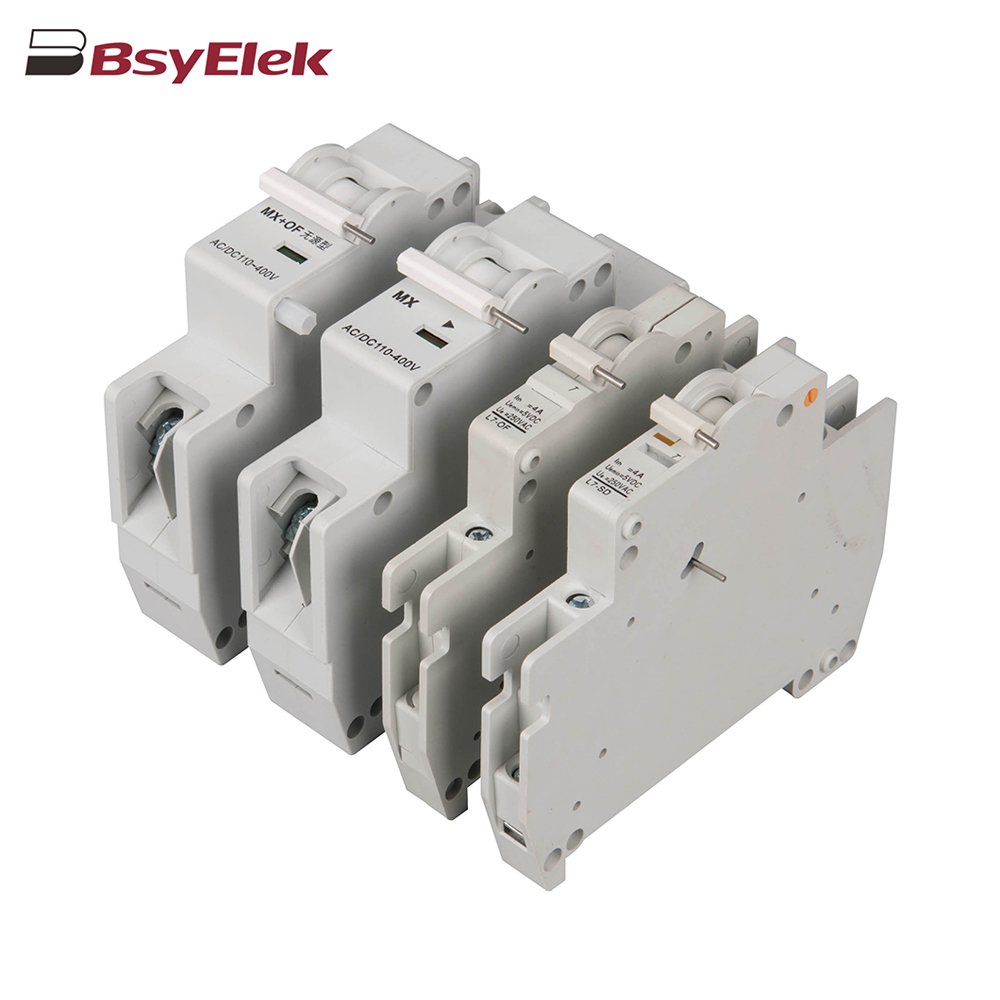

OF SD MX OF MCB Miniature Circuit Breaker Accessories

OF SD MX OF MCB Miniature Circuit Breaker Accessories BYG1-125 Main Switch MCB Isolator Switch

BYG1-125 Main Switch MCB Isolator Switch BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector

BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector

BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector BYX2 6-95A AC Contactor

BYX2 6-95A AC Contactor BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device

BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device

BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device

BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device BY19G 63A Manual Changeover Switch

BY19G 63A Manual Changeover Switch LWSF-125 125A Manual Changeover Switch

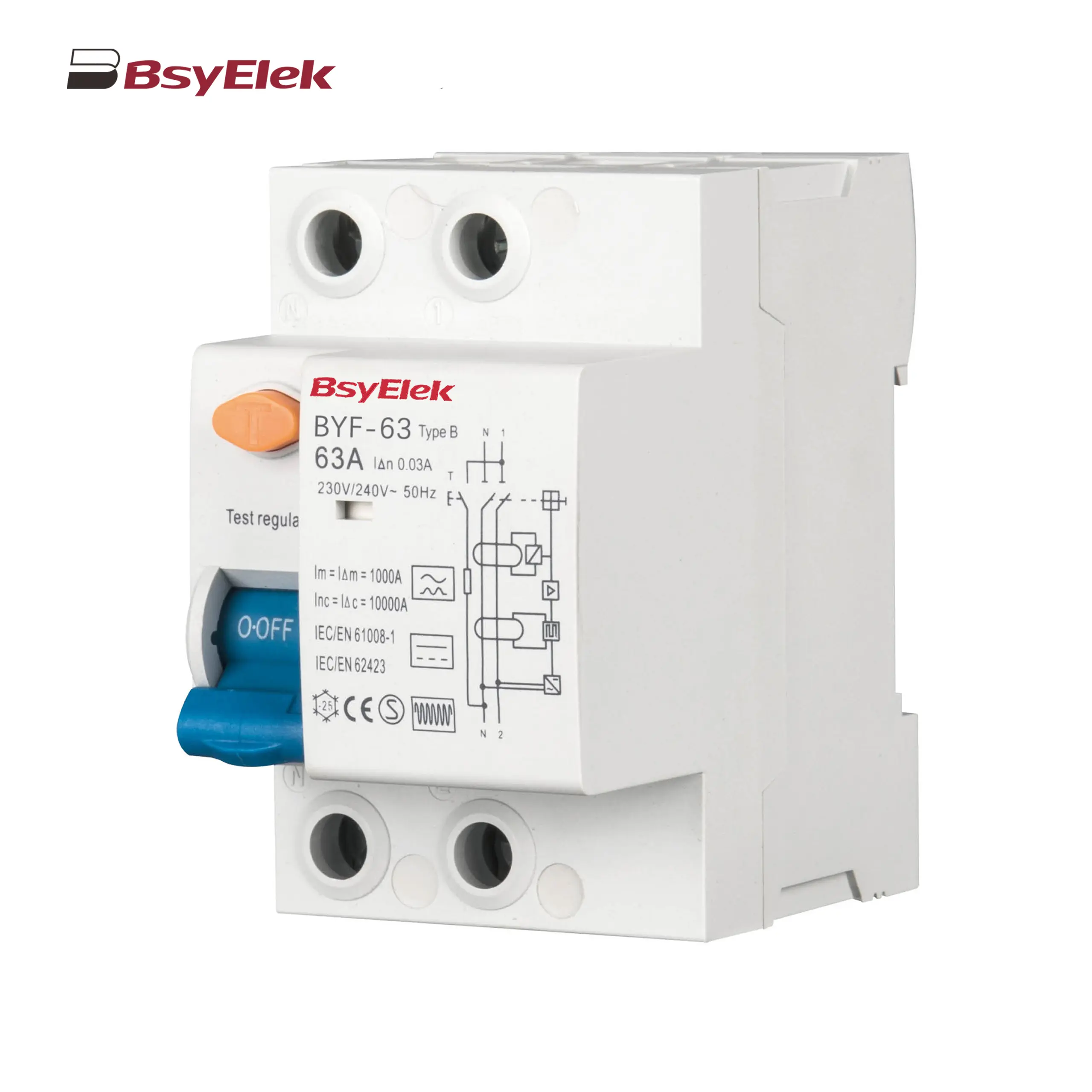

LWSF-125 125A Manual Changeover Switch BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device

BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device

BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device

BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link

BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link

BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link BYPV-ELR2 PV Isolator Switch with Enclosed Version

BYPV-ELR2 PV Isolator Switch with Enclosed Version BYPV-ELR1 PV Isolator Switch with Enclosed Version

BYPV-ELR1 PV Isolator Switch with Enclosed Version BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle

BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle BYPV-NL1 PV Isolator Switch with Lever Handle

BYPV-NL1 PV Isolator Switch with Lever Handle BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle

BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle PV-BY-01 30A/50A 1000V Photovoltaic Connector

PV-BY-01 30A/50A 1000V Photovoltaic Connector PV-BY-02 30A/50A 1500V Photovoltaic Connector

PV-BY-02 30A/50A 1500V Photovoltaic Connector PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector

PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector PV-BY-F01 30A 1500V Diode/Fuse Type Connector

PV-BY-F01 30A 1500V Diode/Fuse Type Connector PV-BY-T 50A 1500V T Type Branch Connector

PV-BY-T 50A 1500V T Type Branch Connector PV-BY-Y 30A 1500V Y Type Branch Connector

PV-BY-Y 30A 1500V Y Type Branch Connector PG Waterproof Cable Gland with Washer

PG Waterproof Cable Gland with Washer Photovoltaic Cable

Photovoltaic Cable HD11N Photovoltaic Knife Switch

HD11N Photovoltaic Knife Switch BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker

BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker

BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker BYM1E MCCB Electronic Type Molded Case Circuit Breaker

BYM1E MCCB Electronic Type Molded Case Circuit Breaker BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker

BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker BYW1 ACB Intelligent Universal Air Circuit Breaker

BYW1 ACB Intelligent Universal Air Circuit Breaker BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch

BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch Stainless Steel Hinge Type Electrical Box

Stainless Steel Hinge Type Electrical Box HA Waterproof Distribution Box

HA Waterproof Distribution Box HT Waterproof Distribution Box

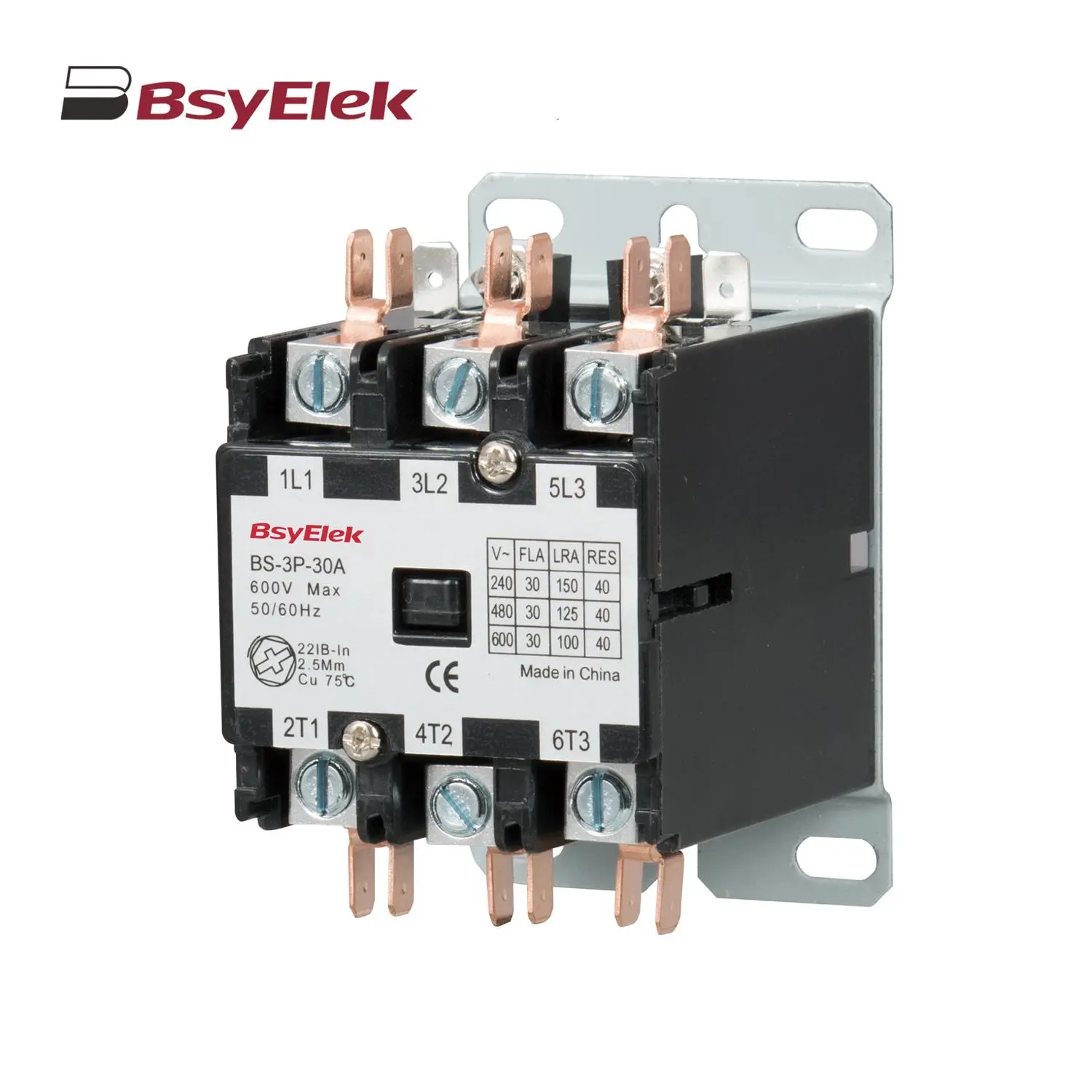

HT Waterproof Distribution Box BS Definite Purpose Magnetic AC Contactor

BS Definite Purpose Magnetic AC Contactor