Top Waterproof Cable Gland Features and Benefits You Need to Know in 2025

In the rapidly evolving landscape of electrical components, the importance of a high-quality Waterproof Cable Gland cannot be overstated. As industries increasingly prioritize safety and reliability, waterproof cable glands are becoming essential in ensuring optimal performance of electrical installations, particularly in harsh environments. According to a recent market report by Smith Industries, the global waterproof cable gland market is projected to grow at a CAGR of 8% through 2025, driven by advancements in technology and the rising demand from sectors such as marine, automotive, and telecommunications.

Industry expert Dr. Emily Thompson, a noted researcher in connectivity solutions, emphasizes the significance of these components: "Waterproof Cable Glands not only protect electrical connections from moisture and contaminants but also enhance the longevity and efficiency of equipment in challenging conditions." Her insights underscore the necessity for professionals in the field to stay informed about the top features and benefits of waterproof cable glands to make educated procurement decisions. As we delve into the critical attributes and advantages of these components in 2025, understanding their role could mean the difference between failure and success in numerous applications.

Key Factors to Consider When Choosing Waterproof Cable Glands

When selecting waterproof cable glands in 2025, several key factors must be taken into consideration to ensure optimal performance and reliability. First, the environmental conditions in which the cable gland will be used are crucial. This includes understanding the temperature ranges, humidity levels, and exposure to chemicals or corrosive substances. A thorough assessment of these conditions will help determine the material of the cable gland, as different materials offer varying levels of resistance to environmental stresses.

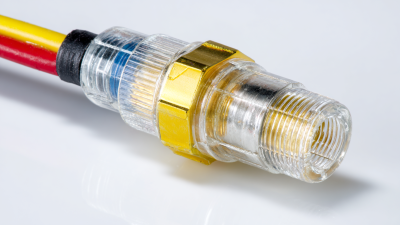

Another important factor is the ingress protection (IP) rating of the cable gland. The IP rating indicates how well the gland can prevent the entry of dust and water. For applications in harsh environments, a higher rating, such as IP68, may be necessary to ensure that the cables remain protected over time. Additionally, consideration should be given to the size and compatibility of the gland with existing cables, as well as ease of installation. A well-designed cable gland can simplify the installation process and provide long-term reliability by minimizing the likelihood of water ingress and mechanical stress on the cables.

Innovative Materials and Technologies for Enhanced Waterproof Performance

The advancements in materials and technologies for waterproof cable glands have taken significant strides in 2025. One of the most notable innovations is the use of high-performance polymers and composites that offer superior resistance to water ingress. These materials not only enhance durability under harsh environmental conditions but also provide flexibility in design, making them suitable for various applications, from marine to industrial settings. Furthermore, the integration of nanotechnology in the manufacturing process has resulted in coatings that repel water more effectively, ensuring that the integrity of electrical connections remains uncompromised.

In addition to material innovations, the development of advanced sealing technologies is enhancing the performance of waterproof cable glands. New designs incorporate multi-layer sealing mechanisms that improve the overall effectiveness of these products. Advanced compression techniques ensure that seals maintain their integrity even under extreme conditions, such as fluctuating temperatures and pressures. These technologies are essential for applications where reliability is critical, allowing for the protection of sensitive electronic components in both indoor and outdoor environments. As awareness grows regarding the environmental impacts of inadequate waterproofing, the industry is moving towards more sustainable solutions, paving the way for a smarter and safer future in waterproof cable gland technology.

Top Waterproof Cable Gland Features and Benefits You Need to Know in 2025

Comparative Advantages of Different Types of Waterproof Cable Glands

When considering waterproof cable glands, it's essential to understand the comparative advantages of various types available in the market. One significant category is the standard brass cable glands, known for their durability and strength. They offer excellent resistance to corrosion and can withstand harsh environmental conditions, making them ideal for outdoor applications. However, for those needing lightweight solutions without compromising performance, nylon cable glands provide a fantastic alternative. They are easy to install and typically more cost-effective, making them suitable for less demanding environments.

Another popular type is the stainless steel cable gland, which combines aesthetic appeal with exceptional resistance to rust and corrosion. This makes them a perfect choice for applications in marine settings or food processing environments where hygiene is paramount. Additionally, these glands can withstand higher temperatures and are mechanically robust, ensuring reliability over time.

Tips: When selecting a waterproof cable gland, always consider the environmental factors it will face, such as temperature fluctuations and exposure to chemicals. Ensure that the chosen gland is compatible with the cables being used to maintain safety and efficiency. Regular inspections can also prevent potential failures, ensuring long-lasting performance in your installations.

Top Waterproof Cable Gland Features and Benefits You Need to Know in 2025 - Comparative Advantages of Different Types of Waterproof Cable Glands

| Type |

IP Rating |

Material |

Temperature Range (°C) |

Benefits |

| Metallic Cable Gland |

IP68 |

Stainless Steel |

-60 to +200 |

Highly durable, ideal for harsh environments |

| Plastic Cable Gland |

IP65 |

Polyamide |

-20 to +100 |

Lightweight, cost-effective for indoor use |

| Explosion-Proof Cable Gland |

IP67 |

Aluminum |

-50 to +150 |

Safe for hazardous locations, robust sealing |

| Flexible Cable Gland |

IP66 |

Thermoplastic Elastomer |

-40 to +120 |

Expands and contracts with cable movement |

Common Applications and Industry Uses for Waterproof Cable Glands in 2025

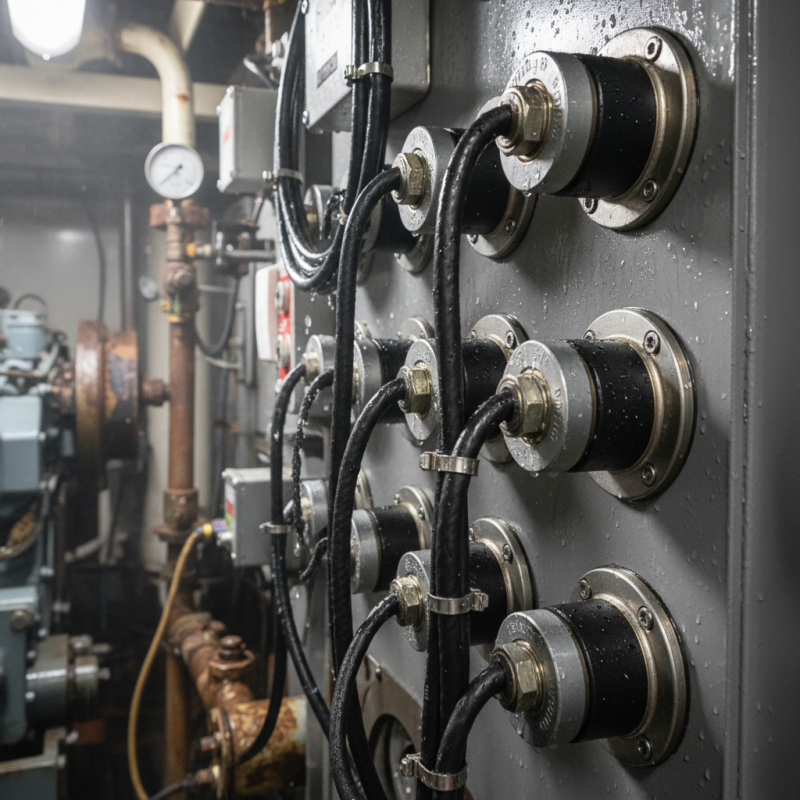

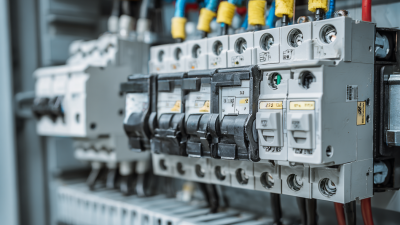

In 2025, waterproof cable glands are essential components across various industries, ensuring the reliable sealing of cables in harsh environments. They are commonly utilized in marine applications, such as shipbuilding and offshore platforms, where exposure to saltwater and moisture can compromise electrical connections. Additionally, industries like construction and automation extensively deploy waterproof cable glands to protect sensitive equipment from water ingress, dust, and other environmental hazards.

When selecting waterproof cable glands, it’s crucial to consider their ratings and certifications, which ensure compatibility with the specific requirements of your application. For instance, IP68-rated glands are ideal for underwater applications, while those rated for higher temperatures should be used in environments exposed to extreme heat.

Tips: Always assess the installation location's environmental conditions to choose the appropriate material, such as nylon or stainless steel, which can offer durability and corrosion resistance. Regular inspections and maintenance of cable glands can also help prevent failures and prolong the lifespan of the electrical systems they protect. Remember that proper installation is key to maximizing the effectiveness of waterproof cable glands, so following the manufacturer’s guidelines is essential.

Maintenance Tips for Ensuring Longevity of Waterproof Cable Glands

Proper maintenance of waterproof cable glands is essential to ensure their longevity and reliable performance in various environmental conditions. According to industry reports, approximately 30% of failures in electrical installations can be attributed to inadequate protection against moisture and contaminants. To mitigate these risks, regular inspections and timely maintenance practices should be implemented. This includes checking the seals for any signs of wear or damage, as compromised seals can lead to water ingress and subsequent failures.

Furthermore, using appropriate cleaning agents that do not damage the materials of the cable glands is crucial. Experts recommend avoiding harsh chemicals that can erode the protective coatings, as this can significantly reduce the lifespan of the glands. Additionally, keeping an eye on the installation environment helps in anticipating potential hazards; for instance, areas exposed to extreme temperatures or saltwater may require more frequent maintenance checks. By establishing a routine that includes these practices, operators can prolong the lifespan of waterproof cable glands, thus enhancing overall safety and reducing costs associated with replacements and repairs.

Home

About Us

Products

Terminal Power Distribution Electric

AC Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

MCB Accessories

Main Switch

RCBO RCCB

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

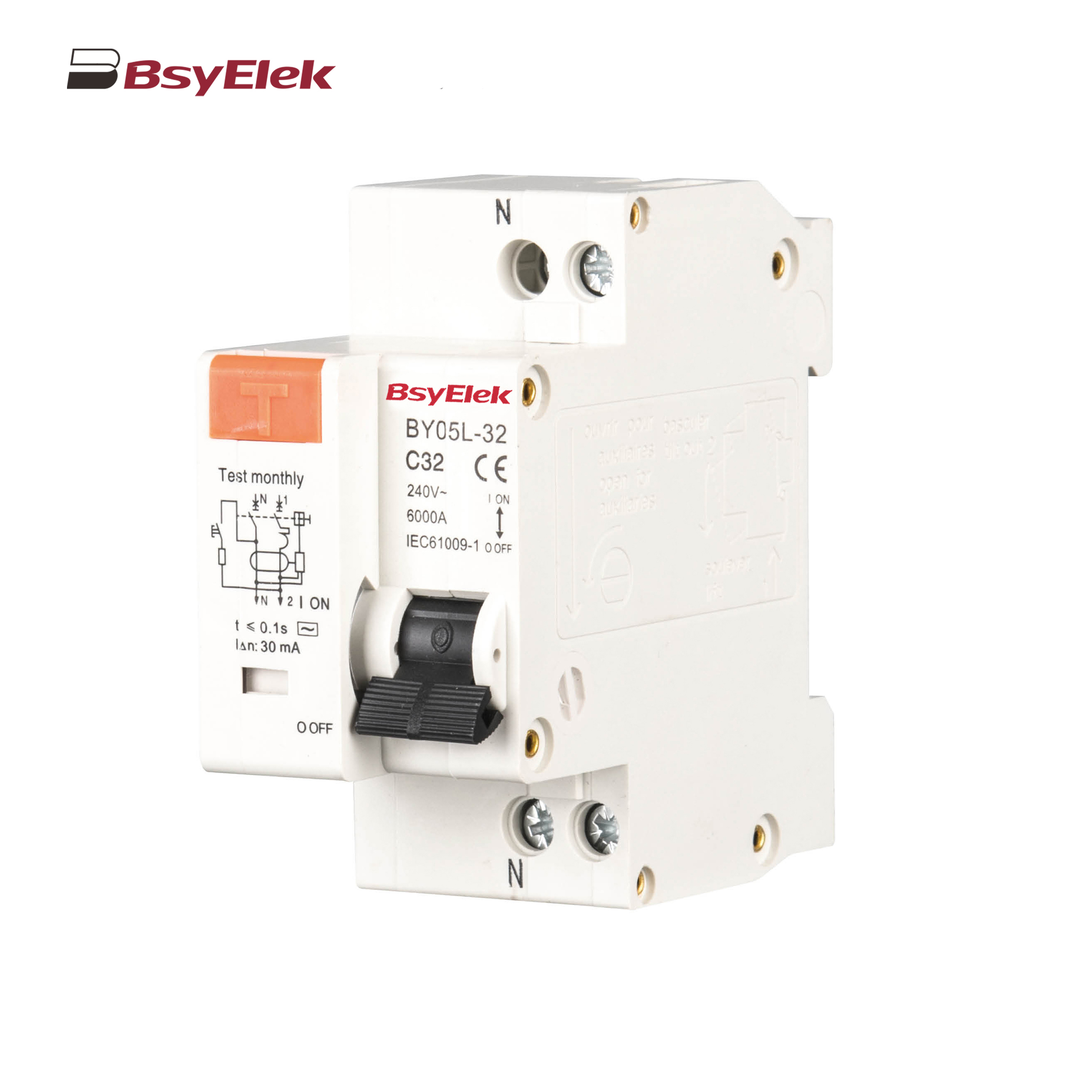

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

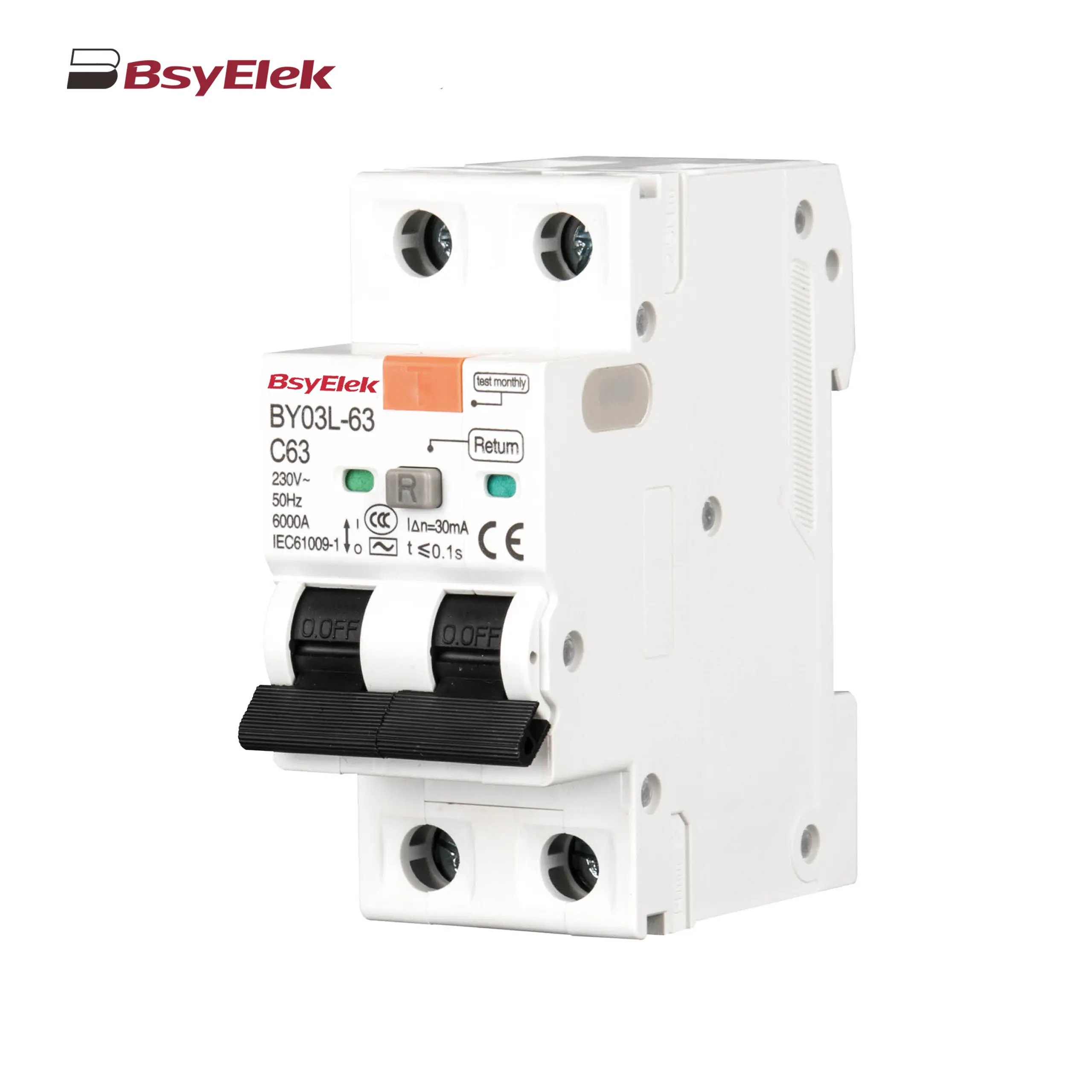

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

Resettable Overvoltage and Undervoltage Protector

AC Contactor

AC Surge Protective Device

Changeover Switch

Photovoltaic System Protection

DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

RCD

DC Surge Protective Device

DC Fuse

PV Isolator Switch

PV Connector

Cable Gland

PV Cable

PV Knife Switch

DC Molded Case Circuit Breaker

Industrial Power Distribution Electric

Distribution Box

Air Conditioning System

Definite Purpose Magnetic Contactor

Condensate Pump

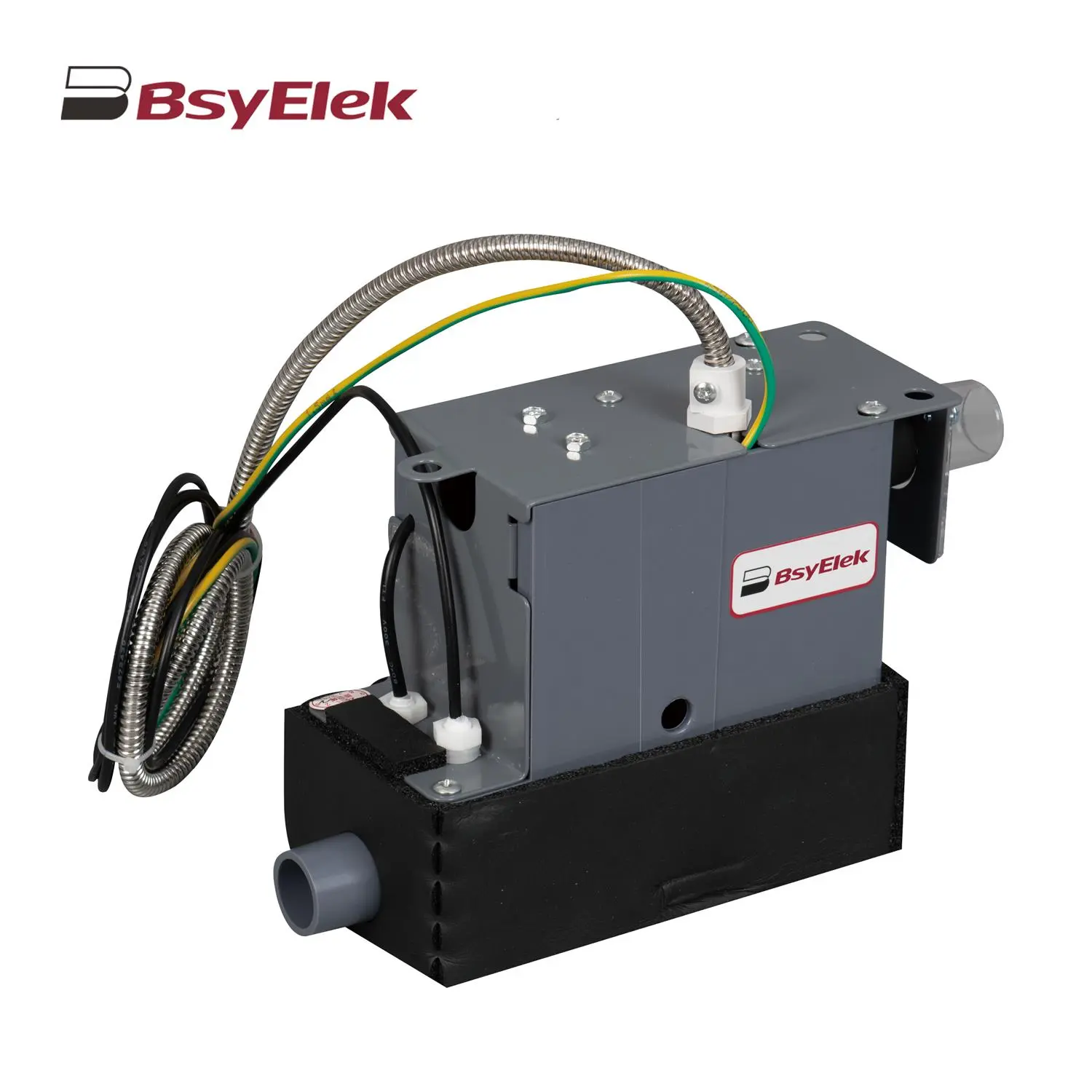

BY-5018 1.8M Engineering Drainage Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-24B/40B 10M Split Type Drainage Pump

BY-24B/40B 10M Split Type Drainage Pump

BY-100L 2M Drainage Pump of Air Conditioner

BY-100L 2M Drainage Pump of Air Conditioner

BY-360L 6M Large Displacement Drainage Pump

BY-360L 6M Large Displacement Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

News

Top Blog

Company News

Industry Dynamics

What is a miniature circuit breaker (MCB)?

PG Series Waterproof Cable Glands with Washer for Harsh Environments

LWSF-125 125A Manual Changeover Switch ensures reliable power transfer

BYX2 AC contactor series: reliable power control for modern electrical systems

High-performance 1000V DC fuse holder optimizes solar photovoltaic system protection

BY07L-63 Residual Current Circuit Breaker Ensures Global Electrical Safety

BYQ5 ATS Isolation Dual Power Automatic Transfer Switch

BY19G 63A Manual Changeover Switch: Features and Benefits

Support

Blog

Contact Us

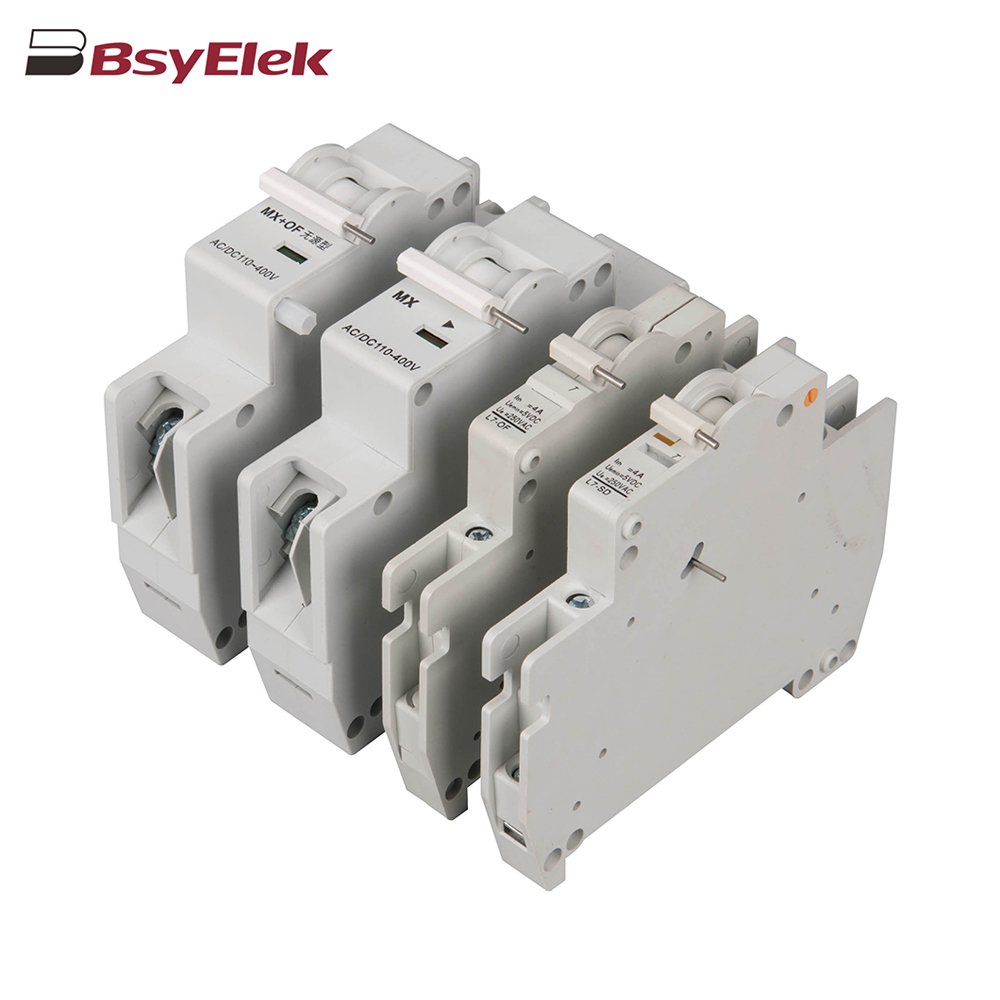

OF SD MX OF MCB Miniature Circuit Breaker Accessories

OF SD MX OF MCB Miniature Circuit Breaker Accessories BYG1-125 Main Switch MCB Isolator Switch

BYG1-125 Main Switch MCB Isolator Switch BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector

BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector

BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector BYX2 6-95A AC Contactor

BYX2 6-95A AC Contactor BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device

BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device

BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device

BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device BY19G 63A Manual Changeover Switch

BY19G 63A Manual Changeover Switch LWSF-125 125A Manual Changeover Switch

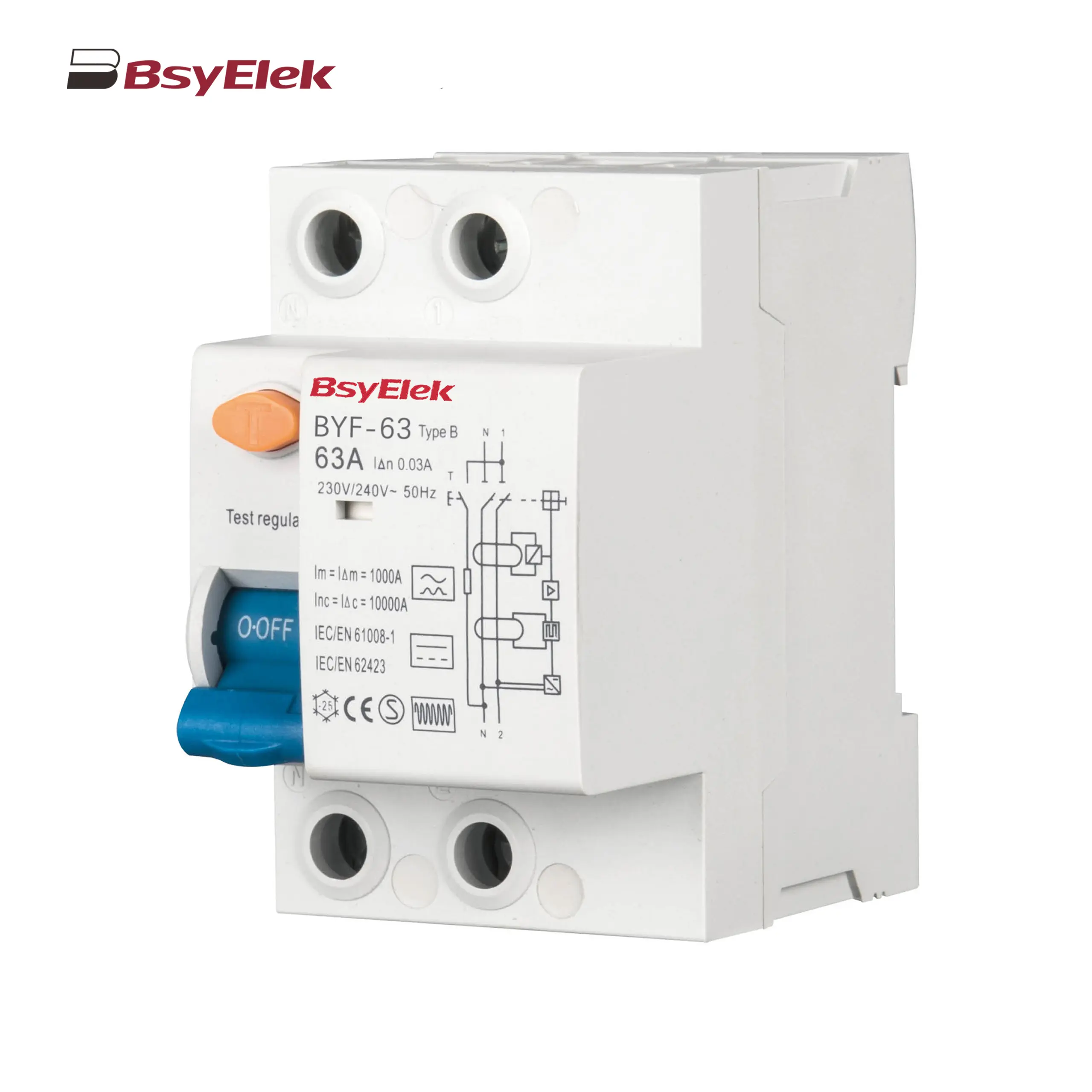

LWSF-125 125A Manual Changeover Switch BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device

BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device

BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device

BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link

BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link

BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link BYPV-ELR2 PV Isolator Switch with Enclosed Version

BYPV-ELR2 PV Isolator Switch with Enclosed Version BYPV-ELR1 PV Isolator Switch with Enclosed Version

BYPV-ELR1 PV Isolator Switch with Enclosed Version BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle

BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle BYPV-NL1 PV Isolator Switch with Lever Handle

BYPV-NL1 PV Isolator Switch with Lever Handle BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle

BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle PV-BY-01 30A/50A 1000V Photovoltaic Connector

PV-BY-01 30A/50A 1000V Photovoltaic Connector PV-BY-02 30A/50A 1500V Photovoltaic Connector

PV-BY-02 30A/50A 1500V Photovoltaic Connector PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector

PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector PV-BY-F01 30A 1500V Diode/Fuse Type Connector

PV-BY-F01 30A 1500V Diode/Fuse Type Connector PV-BY-T 50A 1500V T Type Branch Connector

PV-BY-T 50A 1500V T Type Branch Connector PV-BY-Y 30A 1500V Y Type Branch Connector

PV-BY-Y 30A 1500V Y Type Branch Connector PG Waterproof Cable Gland with Washer

PG Waterproof Cable Gland with Washer Photovoltaic Cable

Photovoltaic Cable HD11N Photovoltaic Knife Switch

HD11N Photovoltaic Knife Switch BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker

BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker

BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker BYM1E MCCB Electronic Type Molded Case Circuit Breaker

BYM1E MCCB Electronic Type Molded Case Circuit Breaker BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker

BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker BYW1 ACB Intelligent Universal Air Circuit Breaker

BYW1 ACB Intelligent Universal Air Circuit Breaker BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch

BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch Stainless Steel Hinge Type Electrical Box

Stainless Steel Hinge Type Electrical Box HA Waterproof Distribution Box

HA Waterproof Distribution Box HT Waterproof Distribution Box

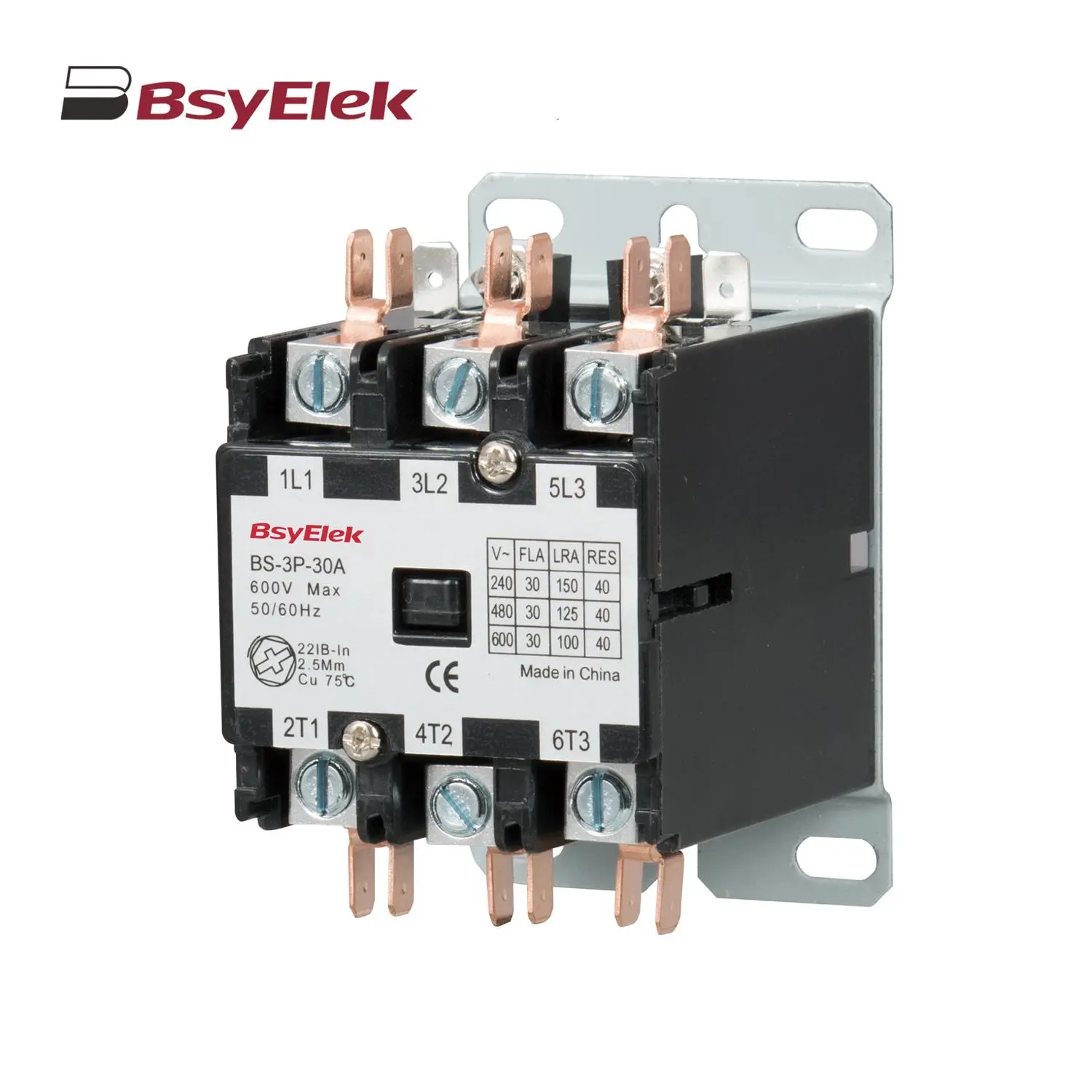

HT Waterproof Distribution Box BS Definite Purpose Magnetic AC Contactor

BS Definite Purpose Magnetic AC Contactor