Essential Tips for Choosing the Right Air Circuit Breaker for Your Needs

When it comes to ensuring the safety and efficiency of electrical systems, selecting the right Air Circuit Breaker (ACB) is crucial. An ACB serves as the first line of defense against electrical overloads and short circuits, offering not only protection but also the capability to manage high electrical loads. Whether you are overseeing a large industrial facility or upgrading your home’s electrical system, understanding the various factors involved in choosing an Air Circuit Breaker can make a significant difference in performance and reliability.

In the rapidly evolving landscape of electrical equipment, knowing how to assess your specific needs is essential. This includes evaluating the electrical load, environmental conditions, and the overall design of your electrical network. A well-chosen Air Circuit Breaker can enhance safety, reduce downtime, and extend the lifespan of your electrical components. As we delve into the essential tips for selecting the right ACB, we will provide practical insights to help you navigate the complexities of this vital electrical device, ensuring your system remains robust and secure.

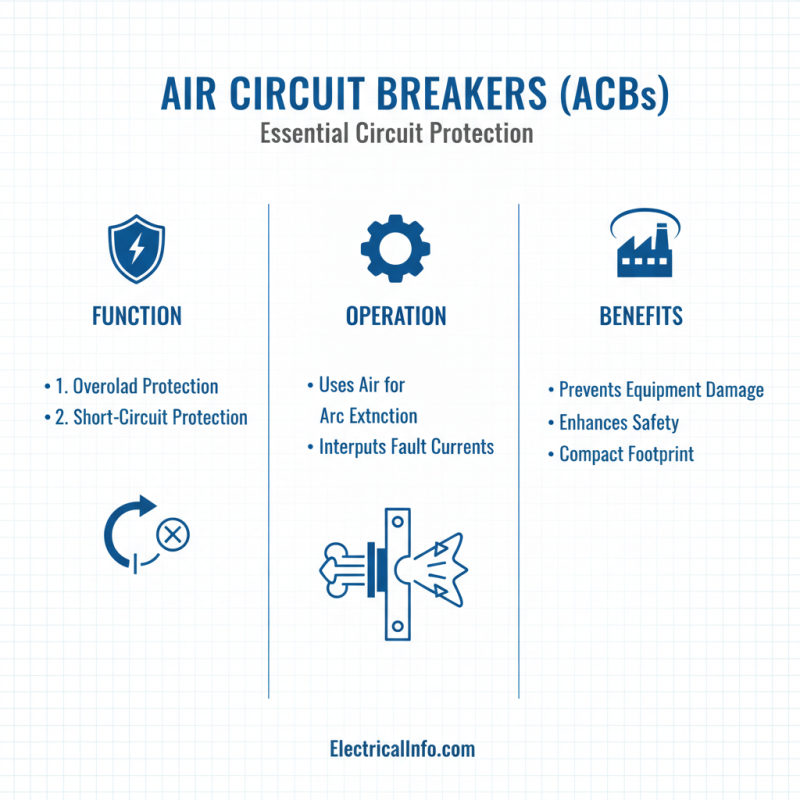

Understanding the Basics of Air Circuit Breakers

Air circuit breakers (ACBs) are essential components in electrical systems, designed to protect circuits from overload and short-circuit conditions. Understanding the basics of ACBs involves recognizing their main functions, which include interruption of current flow during fault conditions and ensuring safety by preventing equipment damage. These devices operate by using air as the primary medium for arc extinction, which allows them to efficiently interrupt fault currents while maintaining a compact footprint.

When selecting an air circuit breaker, it is crucial to consider several factors such as the rated current, breaking capacity, and operational characteristics. The rated current refers to the maximum continuous current the ACB can carry, while the breaking capacity indicates the maximum fault current it can interrupt. Additionally, ACBs come in different configurations and can include features such as adjustable trip settings and remote operation capabilities. Familiarity with these attributes will facilitate informed decision-making and enhance the overall reliability of electrical systems.

Identifying Your Electrical Load Requirements

When selecting the right air circuit breaker (ACB) for your needs, one of the most critical steps is to accurately identify your electrical load requirements. This involves assessing the total amount of electricity your circuits will need to handle under normal operational conditions. Begin by calculating the wattage of all devices and equipment that will be connected to the circuit. This calculation should include both continuous loads and any potential surges for devices that have high startup demands, such as motors and heavy machinery.

It is also essential to consider future expansion when determining load requirements. By evaluating potential increases in equipment or additional circuits, you can choose an ACB with an adequate capacity to accommodate growth. Moreover, paying attention to the load distribution within your electrical system will help in selecting the appropriate trip settings and ensuring optimal protection. In cases of balanced loads, the ACB can operate more efficiently, whereas unbalanced loads might require additional consideration to prevent potential hazards. Taking all these factors into account will ultimately lead to a more reliable and safe electrical system.

Essential Tips for Choosing the Right Air Circuit Breaker for Your Needs

| Load Type |

Load Capacity (Amps) |

Tripping Characteristics |

Application Area |

| Lighting Circuits |

10-30 Amps |

B Curve |

Residential, Commercial |

| HVAC Equipment |

30-100 Amps |

C Curve |

Industrial, Commercial |

| Motor Circuits |

20-250 Amps |

D Curve |

Industrial |

| General Purpose |

40-125 Amps |

B & C Curve |

Commercial, Mixed-use |

Evaluating Environmental and Installation Factors

When selecting the right air circuit breaker, understanding the environmental and installation factors is crucial. The operational environment can significantly influence the performance and longevity of the breaker. For instance, if the circuit breaker is to be installed in a location with high humidity, corrosive elements, or extreme temperatures, it must be rated for such conditions. Breakers designed for harsh environments often feature enhanced insulation and protection mechanisms to ensure reliability and safety. Likewise, considering potential dust or chemical exposure can guide the selection towards models with superior sealing and protective casing.

Installation factors also play a vital role in the decision-making process. The physical space available for the circuit breaker dictates its size and configuration. Compact installations may require breakers with a smaller footprint, while larger systems could accommodate multi-pole configurations. Additionally, evaluating the electrical layout, including proximity to other components and the need for proper ventilation, is essential to ensure optimal functionality. These considerations help avoid overheating and can enhance the overall efficiency of the electrical system, leading to better performance and reduced maintenance needs over time.

Essential Tips for Choosing the Right Air Circuit Breaker

This chart illustrates the importance of various factors when selecting an air circuit breaker, based on their environmental suitability and installation considerations.

Assessing Safety and Compliance Standards

When choosing the right air circuit breaker (ACB) for your needs, assessing safety and compliance standards is crucial. ACBs serve as vital components in electrical systems, protecting equipment and ensuring worker safety. To make an informed selection, start by considering the local and international safety standards relevant to your application, such as IEC or ANSI. Understanding these guidelines will help ensure that the circuit breaker is certified for the operational environment and capable of handling specific voltage and current levels without posing risks.

Additionally, evaluate the compliance certifications of potential ACBs. Look for breakers that meet the required performance criteria and have been tested against stringent safety protocols. This includes thermal, magnetic, and short-circuit protection ratings, which are essential for preventing equipment damage and electrical hazards. It is also beneficial to consider breakers with built-in monitoring features that can provide real-time data on system performance, alerting you to potential issues before they become critical. By placing a strong emphasis on safety and compliance standards, you can select an ACB that not only meets regulatory requirements but also enhances the overall reliability of your electrical systems.

Comparing Features and Manufacturer Options

When selecting the right air circuit breaker (ACB) for specific applications, it is essential to explore various features and options available from different manufacturers. Key factors to consider include the voltage rating, current-carrying capacity, and the breaking capacity of the circuit breaker. According to a recent report by MarketsandMarkets, the global air circuit breaker market is projected to reach USD 4.1 billion by 2025, highlighting the growing demand for reliable circuit protection in industrial and commercial settings.

Comparing features across manufacturers can significantly impact the performance and efficiency of the electrical systems being protected. For instance, some ACBs come equipped with advanced digital trip units that provide precise monitoring and custom settings, which enhance fault detection and minimize downtime in operations. Furthermore, manufacturers are increasingly adopting eco-friendly designs and materials in their ACB products, aligning with global sustainability goals. A report by Research and Markets indicates that the increasing emphasis on energy efficiency and sustainability is driving innovations in electrical protection devices, underscoring the importance of informed comparisons when choosing an ACB.

Ultimately, a thorough assessment of the various options available from multiple manufacturers can ensure that end-users choose an air circuit breaker that not only meets their technical specifications but also aligns with industry trends and future requirements. Understanding the unique offerings of different manufacturers can lead to better safety and performance in electrical installations.

Home

About Us

Products

Terminal Power Distribution Electric

AC Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

MCB Accessories

Main Switch

RCBO RCCB

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

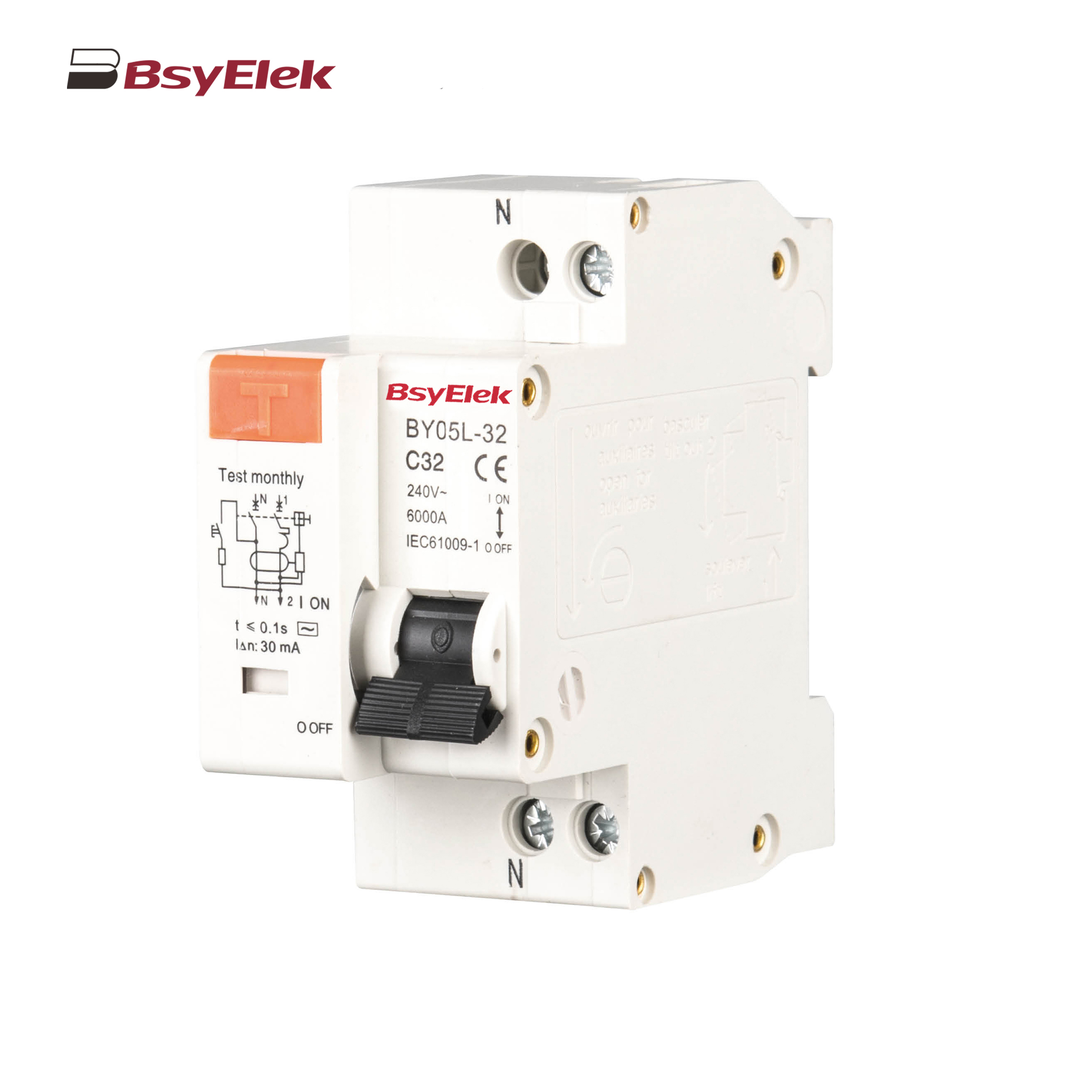

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

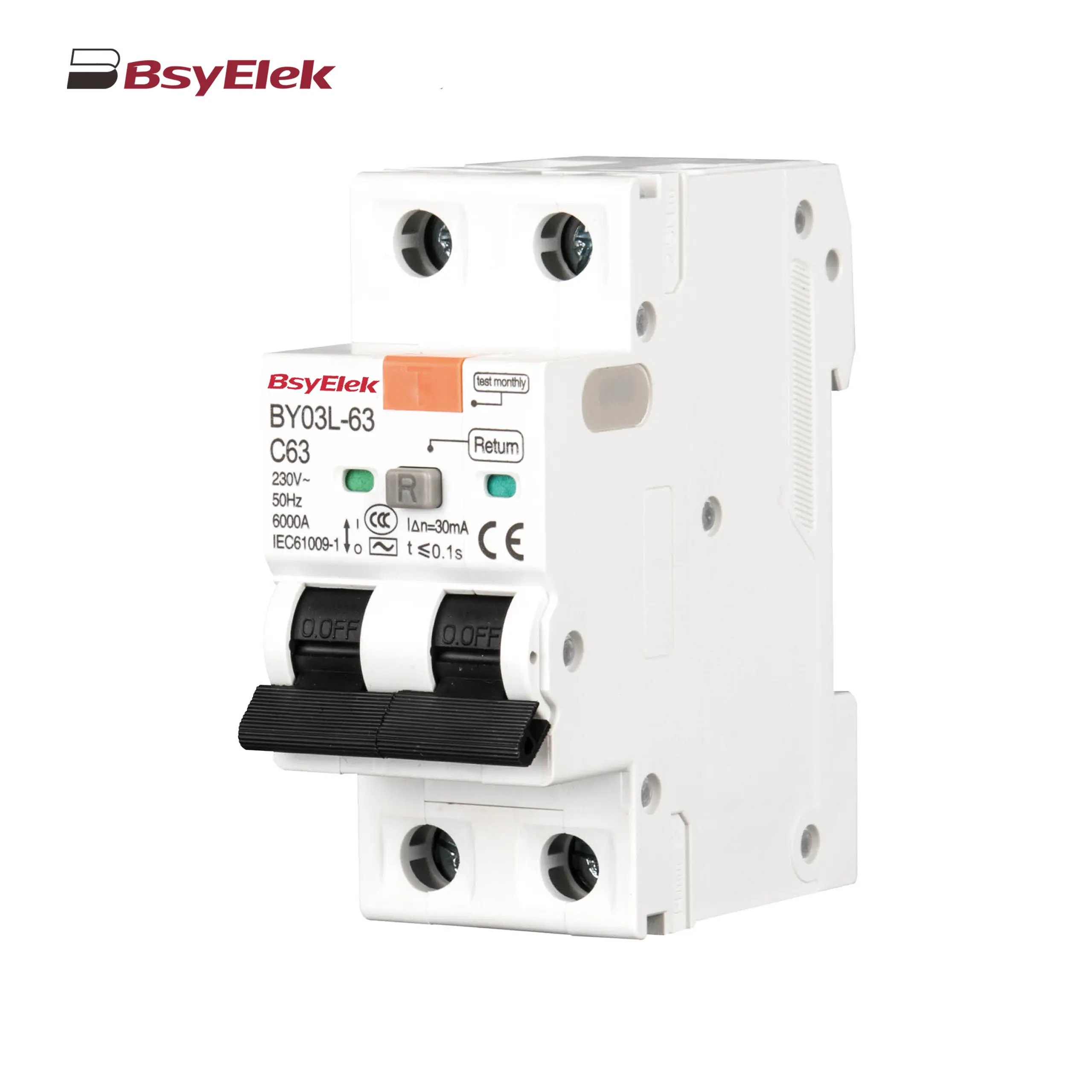

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

Resettable Overvoltage and Undervoltage Protector

AC Contactor

AC Surge Protective Device

Changeover Switch

Photovoltaic System Protection

DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

RCD

DC Surge Protective Device

DC Fuse

PV Isolator Switch

PV Connector

Cable Gland

PV Cable

PV Knife Switch

DC Molded Case Circuit Breaker

Industrial Power Distribution Electric

Distribution Box

Air Conditioning System

Definite Purpose Magnetic Contactor

Condensate Pump

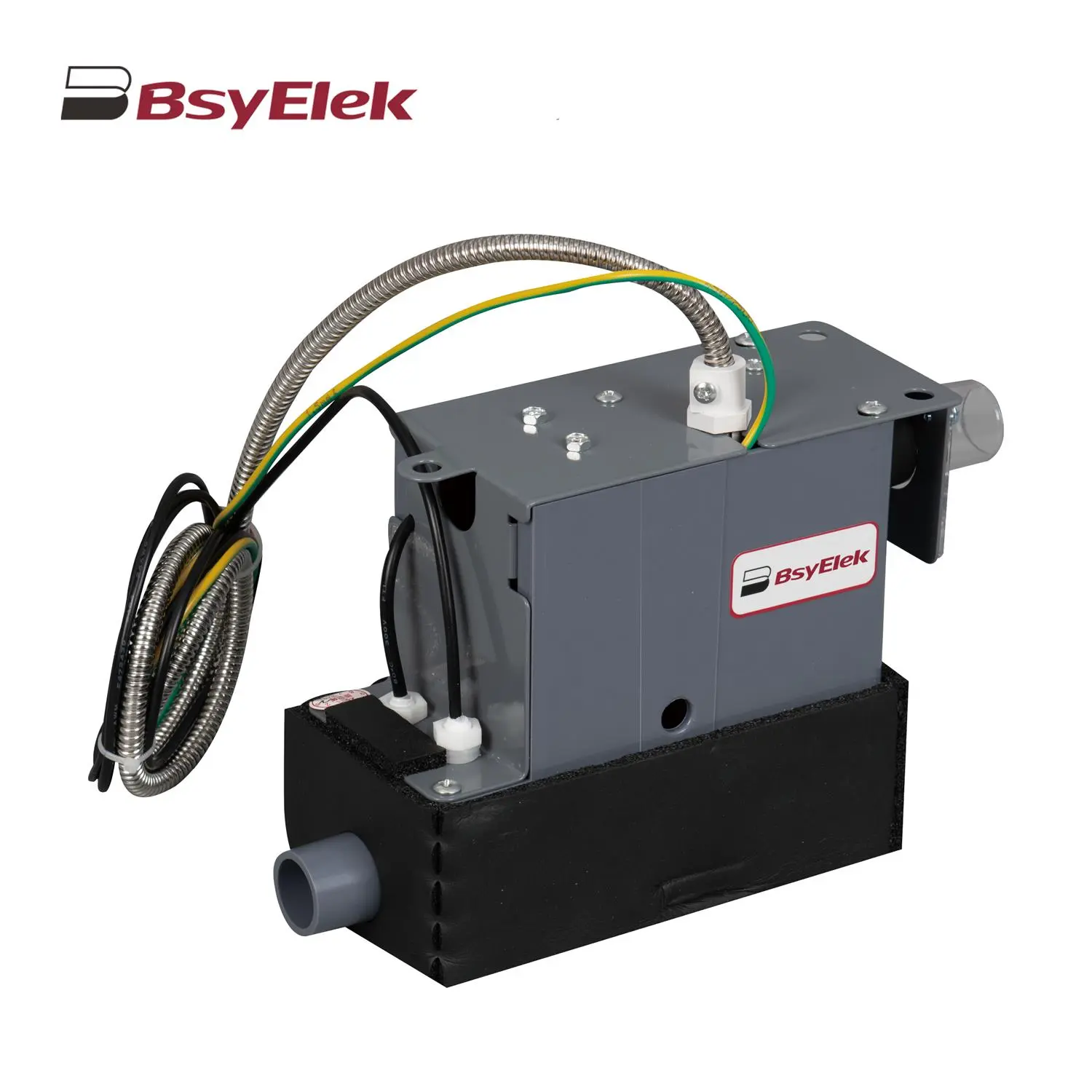

BY-5018 1.8M Engineering Drainage Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-24B/40B 10M Split Type Drainage Pump

BY-24B/40B 10M Split Type Drainage Pump

BY-100L 2M Drainage Pump of Air Conditioner

BY-100L 2M Drainage Pump of Air Conditioner

BY-360L 6M Large Displacement Drainage Pump

BY-360L 6M Large Displacement Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

News

Top Blog

Company News

Industry Dynamics

What is a miniature circuit breaker (MCB)?

PG Series Waterproof Cable Glands with Washer for Harsh Environments

LWSF-125 125A Manual Changeover Switch ensures reliable power transfer

BYX2 AC contactor series: reliable power control for modern electrical systems

High-performance 1000V DC fuse holder optimizes solar photovoltaic system protection

BY07L-63 Residual Current Circuit Breaker Ensures Global Electrical Safety

BYQ5 ATS Isolation Dual Power Automatic Transfer Switch

BY19G 63A Manual Changeover Switch: Features and Benefits

Support

Blog

Contact Us

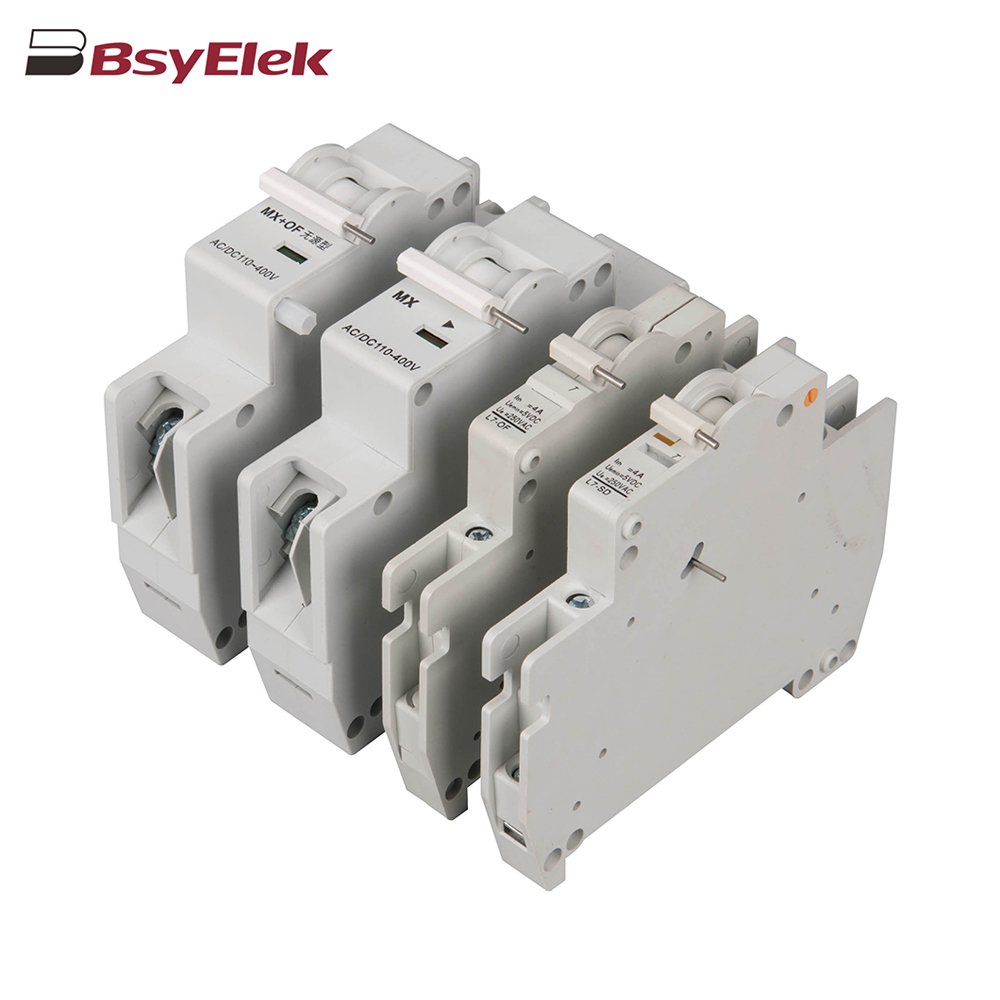

OF SD MX OF MCB Miniature Circuit Breaker Accessories

OF SD MX OF MCB Miniature Circuit Breaker Accessories BYG1-125 Main Switch MCB Isolator Switch

BYG1-125 Main Switch MCB Isolator Switch BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector

BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector

BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector BYX2 6-95A AC Contactor

BYX2 6-95A AC Contactor BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device

BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device

BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device

BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device BY19G 63A Manual Changeover Switch

BY19G 63A Manual Changeover Switch LWSF-125 125A Manual Changeover Switch

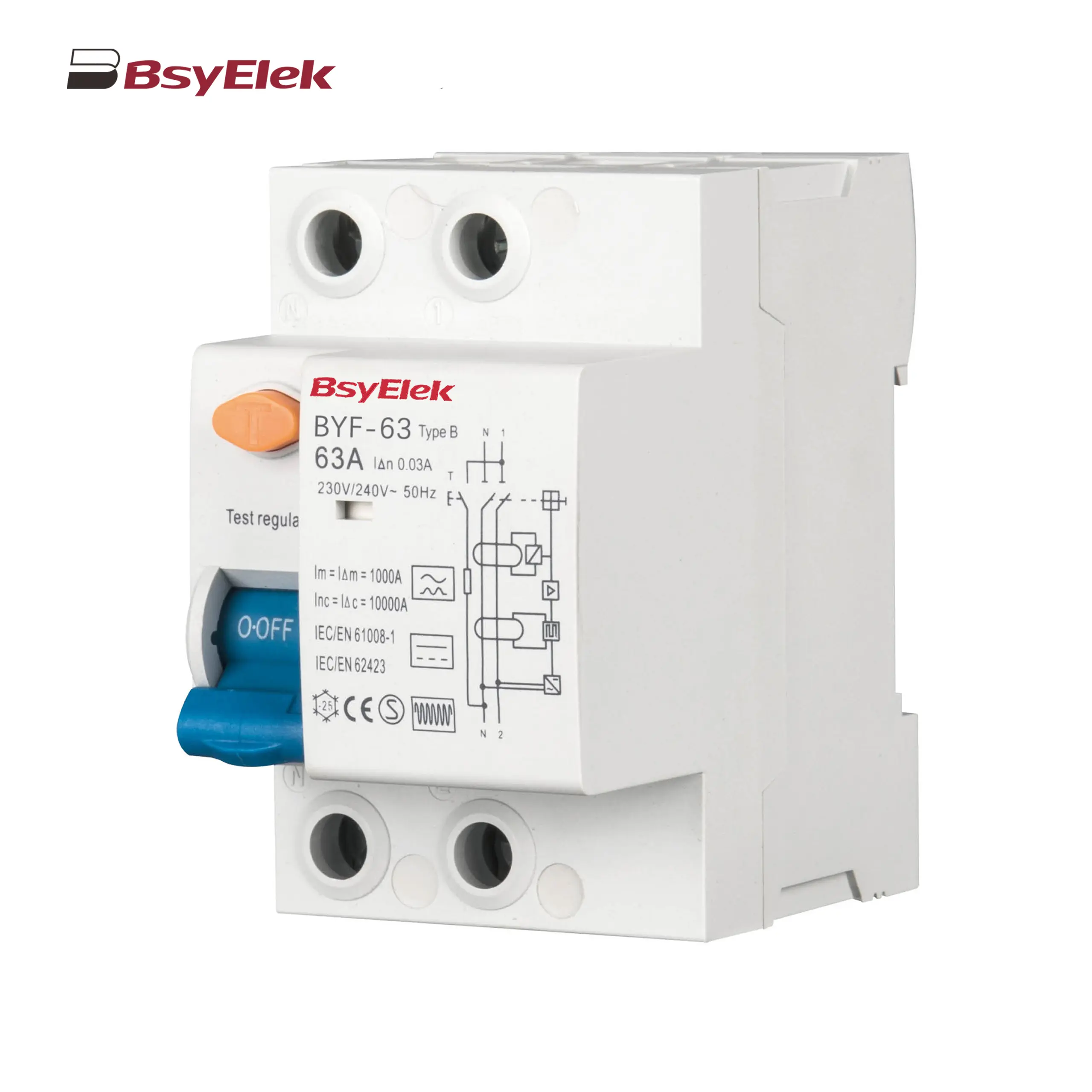

LWSF-125 125A Manual Changeover Switch BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device

BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device

BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device

BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link

BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link

BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link BYPV-ELR2 PV Isolator Switch with Enclosed Version

BYPV-ELR2 PV Isolator Switch with Enclosed Version BYPV-ELR1 PV Isolator Switch with Enclosed Version

BYPV-ELR1 PV Isolator Switch with Enclosed Version BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle

BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle BYPV-NL1 PV Isolator Switch with Lever Handle

BYPV-NL1 PV Isolator Switch with Lever Handle BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle

BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle PV-BY-01 30A/50A 1000V Photovoltaic Connector

PV-BY-01 30A/50A 1000V Photovoltaic Connector PV-BY-02 30A/50A 1500V Photovoltaic Connector

PV-BY-02 30A/50A 1500V Photovoltaic Connector PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector

PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector PV-BY-F01 30A 1500V Diode/Fuse Type Connector

PV-BY-F01 30A 1500V Diode/Fuse Type Connector PV-BY-T 50A 1500V T Type Branch Connector

PV-BY-T 50A 1500V T Type Branch Connector PV-BY-Y 30A 1500V Y Type Branch Connector

PV-BY-Y 30A 1500V Y Type Branch Connector PG Waterproof Cable Gland with Washer

PG Waterproof Cable Gland with Washer Photovoltaic Cable

Photovoltaic Cable HD11N Photovoltaic Knife Switch

HD11N Photovoltaic Knife Switch BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker

BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker

BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker BYM1E MCCB Electronic Type Molded Case Circuit Breaker

BYM1E MCCB Electronic Type Molded Case Circuit Breaker BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker

BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker BYW1 ACB Intelligent Universal Air Circuit Breaker

BYW1 ACB Intelligent Universal Air Circuit Breaker BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch

BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch Stainless Steel Hinge Type Electrical Box

Stainless Steel Hinge Type Electrical Box HA Waterproof Distribution Box

HA Waterproof Distribution Box HT Waterproof Distribution Box

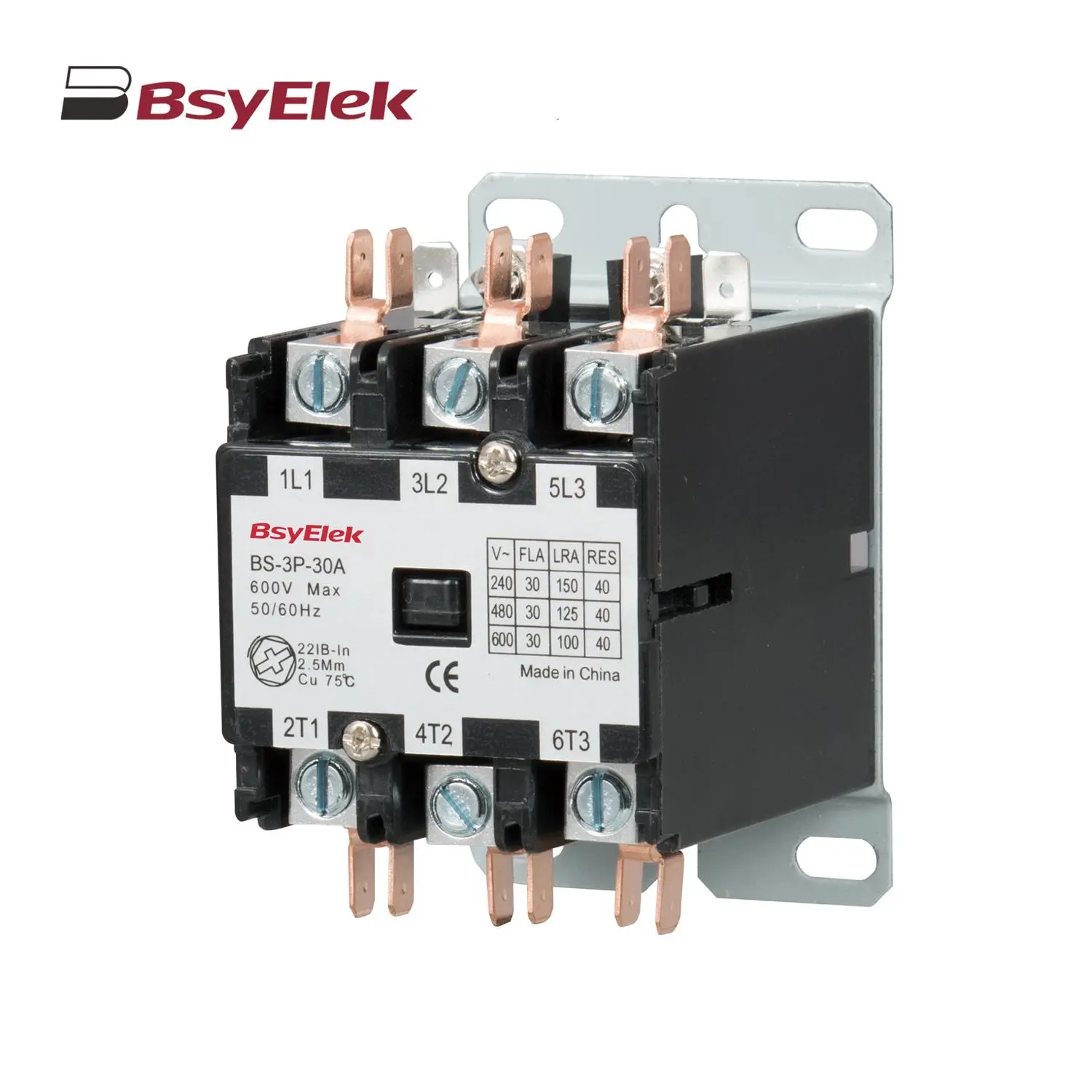

HT Waterproof Distribution Box BS Definite Purpose Magnetic AC Contactor

BS Definite Purpose Magnetic AC Contactor