Understanding the Role of Distribution Box in Modern Electrical Systems

In today's rapidly evolving electrical landscape, the

Distribution Box plays a

crucial role in ensuring the safe and efficient management of electrical circuits within

buildings and infrastructure. According to a report by MarketsandMarkets, the global

electrical distribution equipment market is projected to

reach USD 140.29 billion by 2025, growing at a CAGR of 5.8% from

2020. This substantial growth underscores the importance of reliable distribution systems

in modern electrical engineering practices. The Distribution Box, often referred to as a

panel board or distribution board, serves as the central hub for distributing electricity

to various circuits, thereby enhancing electrical safety and operational efficiency. As we

delve into its components, functionalities, and best practices, we will gain a comprehensive

understanding of how the Distribution Box

is integral to the design and maintenance of contemporary electrical systems, making it a

vital topic for both professionals and enthusiasts in the field.

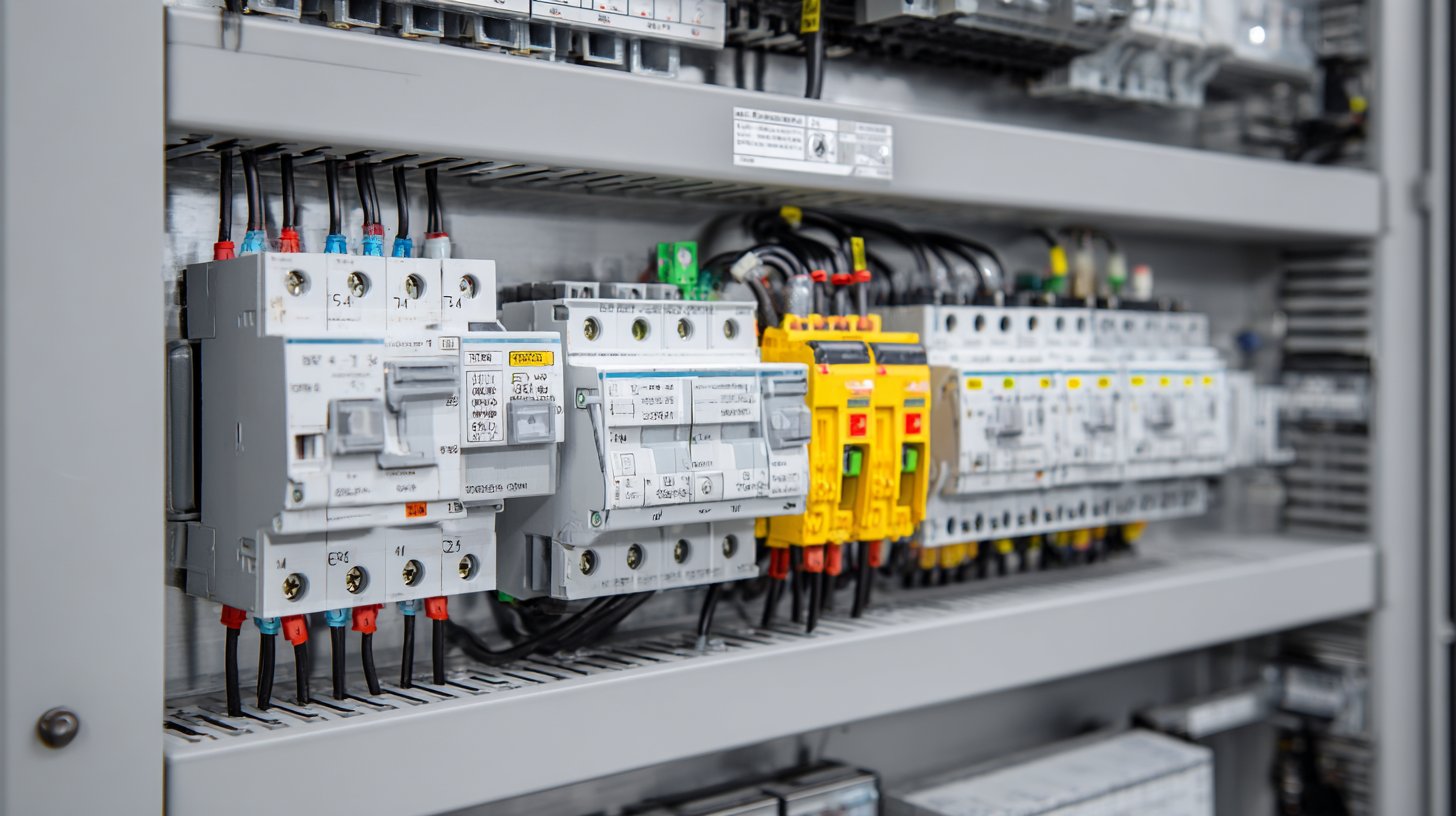

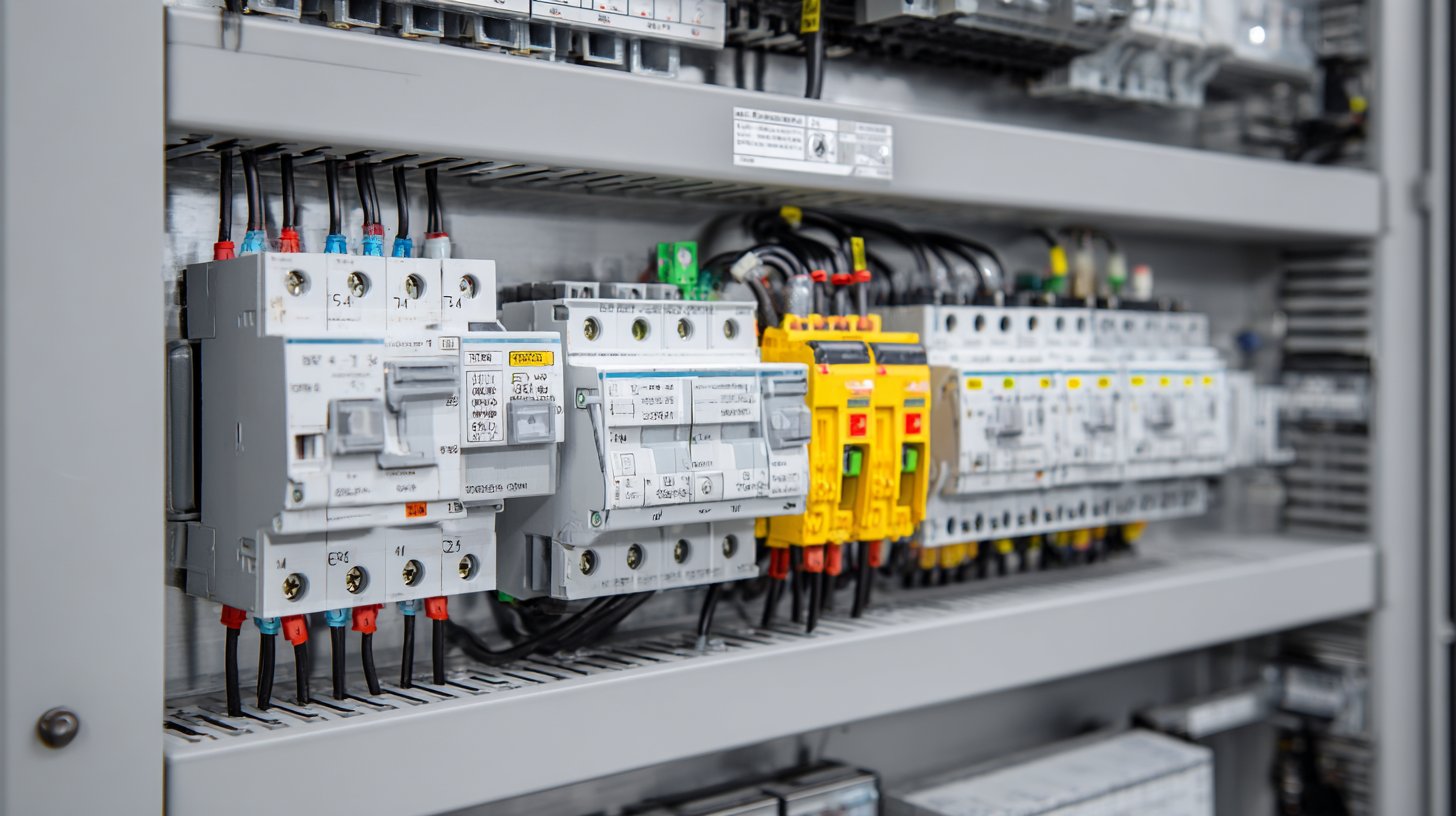

The Evolution of Distribution Boxes: From Traditional to Modern Alternatives

The evolution of distribution boxes has significantly transformed modern electrical systems, reflecting both technological advancements and changing safety standards. Historically, traditional distribution boxes, often characterized by their relatively simplistic design and materials, were sufficient for basic power distribution needs. However, as electrical demands increased with the proliferation of residential and commercial technologies, these conventional systems began to show their limitations. According to a recent report by the International Electrotechnical Commission (IEC), roughly 70% of electrical failures in facilities can be traced back to outdated or inadequate distribution systems.

In response to these challenges, modern alternatives to traditional distribution boxes now incorporate advanced materials and smart technology features. Innovations such as modular designs and integrated circuit protection have enhanced safety and efficiency. The market for digital distribution boxes is projected to grow at a compound annual growth rate (CAGR) of 5.5% from 2022 to 2028, driven by the increasing adoption of smart grids and the need for more reliable energy management solutions. This evolution is not just about improving performance; it also focuses on sustainability, with many manufacturers now prioritizing eco-friendly materials and energy-efficient designs to meet the rising demand for greener electrical systems.

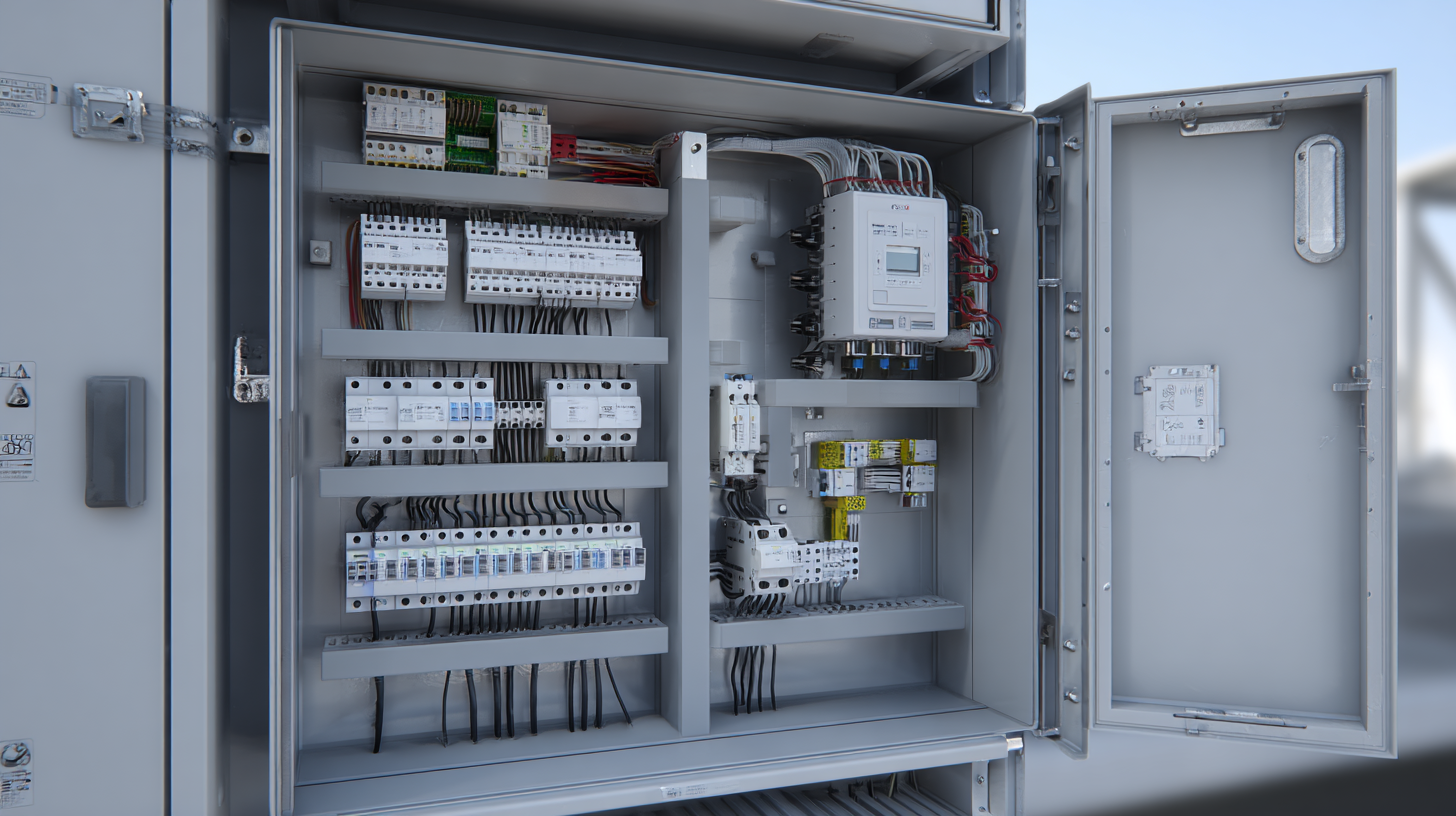

Exploring the Benefits of Modular Distribution Boxes in Flexible Electrical Systems

Understanding the role of distribution boxes in modern electrical systems is becoming increasingly important, especially as we transition to more flexible and energy-efficient solutions. Modular distribution boxes offer significant benefits, such as ease of installation and adaptability to various power requirements. These systems streamline design processes, allowing for faster assembly and adjustments as electrical needs evolve.

Tips for optimizing your electrical system with modular distribution boxes include assessing current and projected power demands to ensure the distribution box can accommodate future expansions. Additionally, consider integrating digital intelligence tools for diagnostics, which can enhance the reliability of your electrical distribution assets and prevent downtime.

As industries increasingly prioritize renewable energy, the demand for efficient modular wiring systems will only grow. With a focus on sustainability and operational flexibility, embracing these advanced distribution solutions can significantly enhance energy management across various applications, from data centers to commercial buildings.

Benefits of Modular Distribution Boxes in Modern Electrical Systems

This chart illustrates the key benefits of modular distribution boxes in modern electrical systems, highlighting aspects such as cost efficiency, flexibility, ease of maintenance, safety, and scalability. Each category represents a percentage score based on overall advantages observed in various electrical system implementations.

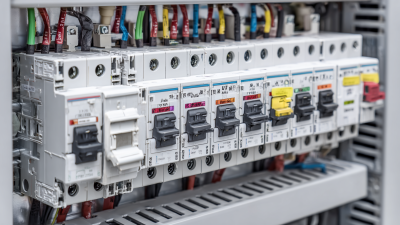

Comparative Analysis: Standard Distribution Boxes vs. Smart Distribution Solutions

In today's rapidly evolving electrical landscape, the choice between standard distribution boxes and smart distribution solutions has significant implications for efficiency and safety. Standard distribution boxes have long served as the backbone of electrical systems, offering straightforward functionality with limited monitoring capabilities. They effectively manage the distribution of electricity but often do not provide real-time data about power usage or system operations.

On the other hand, smart distribution solutions are increasingly becoming the norm due to their advanced features. These systems integrate technology that allows for remote monitoring and control, energy management, and enhanced safety protocols. Users can access data via mobile applications, enabling them to analyze power consumption patterns and identify potential issues before they escalate.

Tip: When choosing a distribution box, assess your specific needs and future scalability. Smart solutions may require a higher initial investment, but they often lead to long-term savings through improved energy efficiency and automation. Also, consider the ease of integration with existing systems to ensure a smooth transition to modern electrical management.

Enhancing Safety and Efficiency: The Role of Alternative Materials in Distribution Boxes

In modern electrical systems, the distribution box serves as a crucial hub, managing the flow of electrical power safely and efficiently. Traditionally, these boxes were constructed from metal materials that, while robust, posed challenges such as corrosion and increased weight. However, the advent of alternative materials has revolutionized the design and functionality of distribution boxes, enhancing both safety and efficiency. Composite materials, for example, offer excellent insulation properties and resistance to environmental factors, thereby reducing the overall risk of electrical hazards.

Additionally, the integration of lightweight and durable materials allows for easier installation and maintenance of distribution boxes. Engineers can now design more compact systems without compromising on strength or safety. The use of polycarbonate and fiberglass has become increasingly popular, enabling manufacturers to create boxes that withstand extreme conditions while remaining cost-effective. This shift not only ensures compliance with stringent safety regulations but also optimizes energy distribution, leading to improved overall performance of modern electrical systems. By leveraging these innovative materials, the industry is moving towards a future that prioritizes both functionality and safety in electrical distribution.

Understanding the Role of Distribution Box in Modern Electrical Systems - Enhancing Safety and Efficiency: The Role of Alternative Materials in Distribution Boxes

| Material Type |

Benefits |

Safety Features |

Efficiency Enhancements |

Cost per Unit |

| Polycarbonate |

High impact resistance, lightweight |

Flame retardant properties |

Improves thermal efficiency |

$15 |

| Fiberglass |

Corrosion resistant, durable |

Non-combustible |

Excellent thermal insulation |

$20 |

| Stainless Steel |

High strength and longevity |

Robust against external hazards |

High reliability in severe conditions |

$25 |

| Aluminum |

Lightweight, good conductivity |

Anodized for enhanced safety |

Reduces energy loss |

$18 |

Case Studies: Successful Implementations of Alternative Distribution Box Designs

The role of the distribution box within modern electrical systems is crucial, as it serves as the central hub for electrical distribution in residential and commercial buildings. Various innovative designs have emerged, showcasing how alternative distribution box configurations can enhance both functionality and safety. One prominent case study involves a smart distribution box that integrates IoT technology. This design incorporates real-time monitoring capabilities, allowing users to track energy consumption and detect potential faults immediately. By implementing such systems, facility managers can significantly improve energy efficiency and reduce the risk of electrical fires.

Another exemplary case is the use of modular distribution boxes in a large-scale commercial project. These boxes are designed to be easily expandable and customizable, which allows for seamless upgrades as the electrical demands of the building evolve. This flexibility is particularly beneficial in dynamic environments such as co-working spaces, where tenant needs frequently change. The successful execution of this modular design demonstrates its cost-effectiveness and adaptability, paving the way for broader adoption in future electrical installations.

Home

About Us

Products

Terminal Power Distribution Electric

AC Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

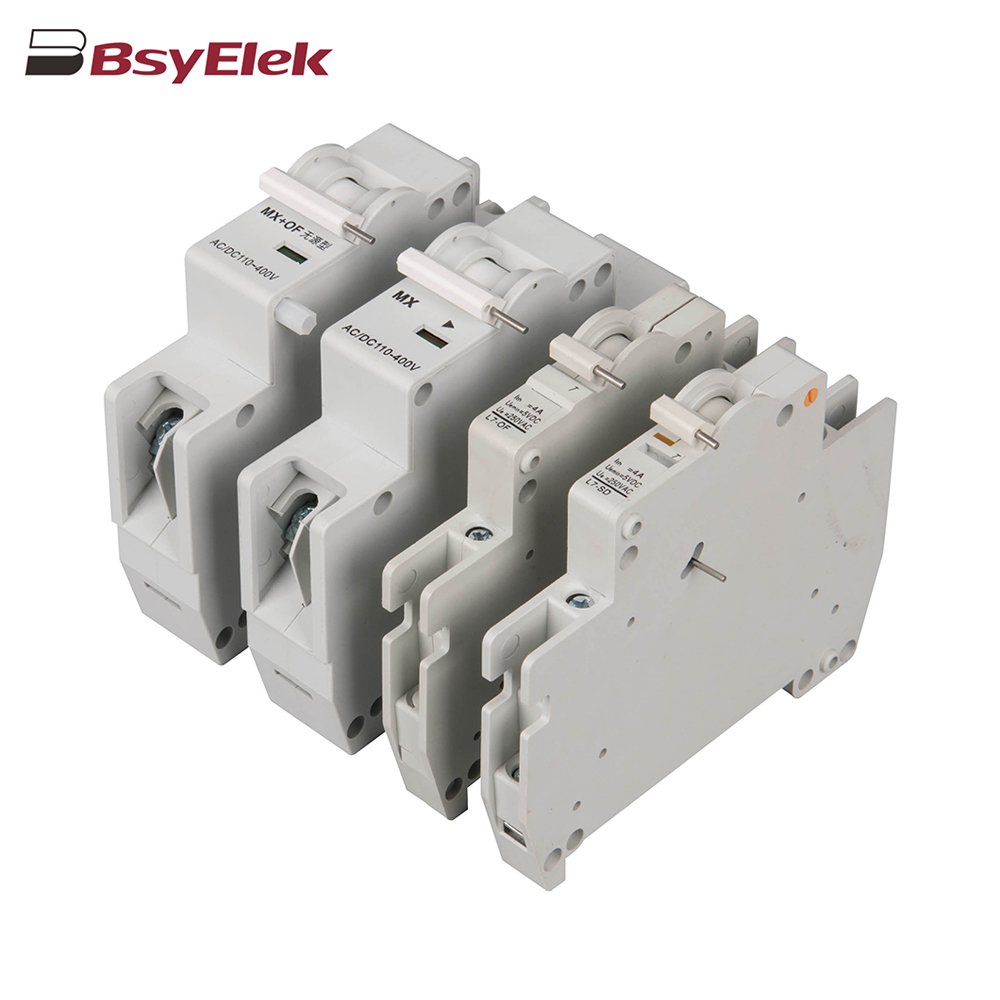

MCB Accessories

Main Switch

RCBO RCCB

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

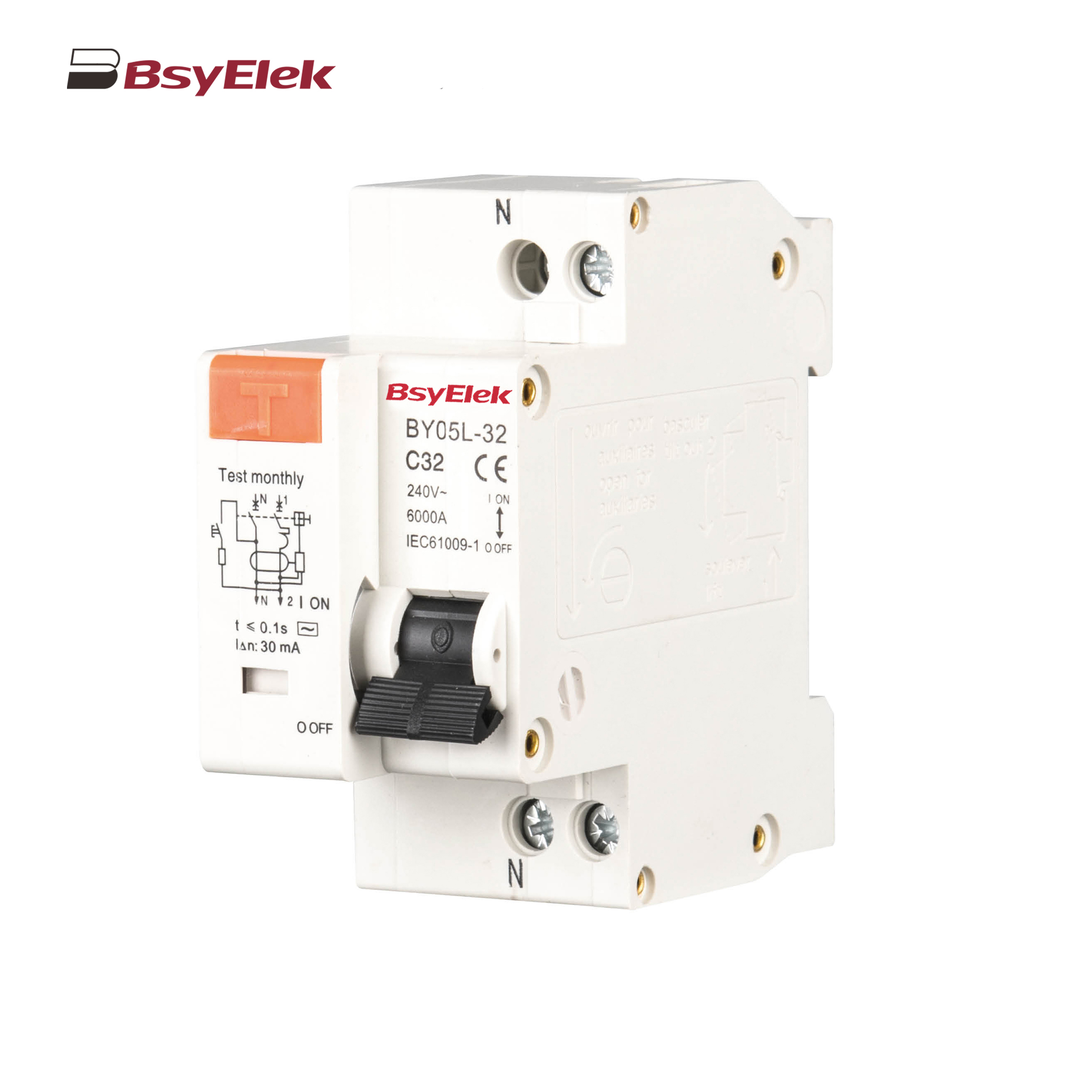

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

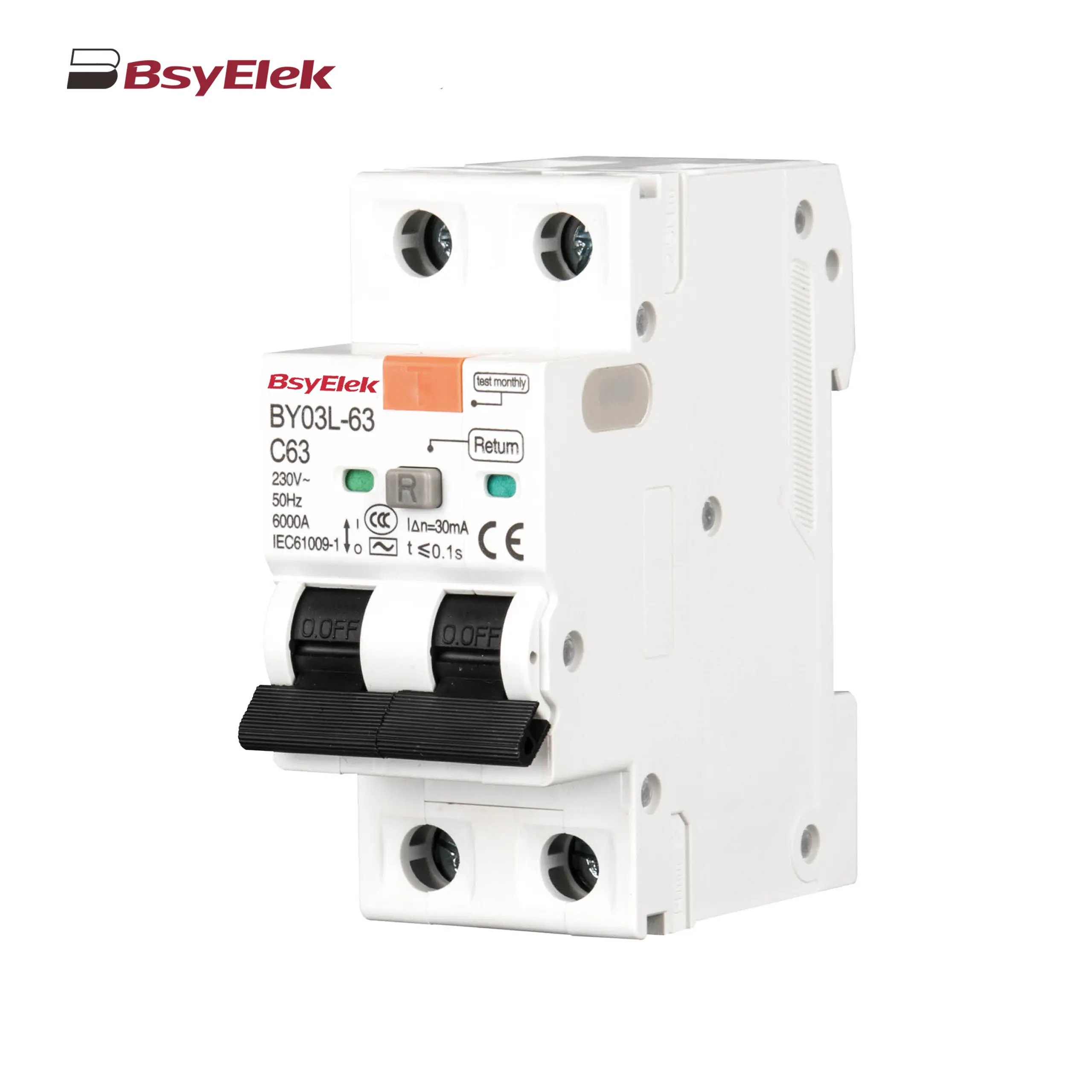

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

Resettable Overvoltage and Undervoltage Protector

AC Contactor

AC Surge Protective Device

Changeover Switch

Photovoltaic System Protection

DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

RCD

DC Surge Protective Device

DC Fuse

PV Isolator Switch

PV Connector

Cable Gland

PV Cable

PV Knife Switch

DC Molded Case Circuit Breaker

Industrial Power Distribution Electric

Distribution Box

Air Conditioning System

Definite Purpose Magnetic Contactor

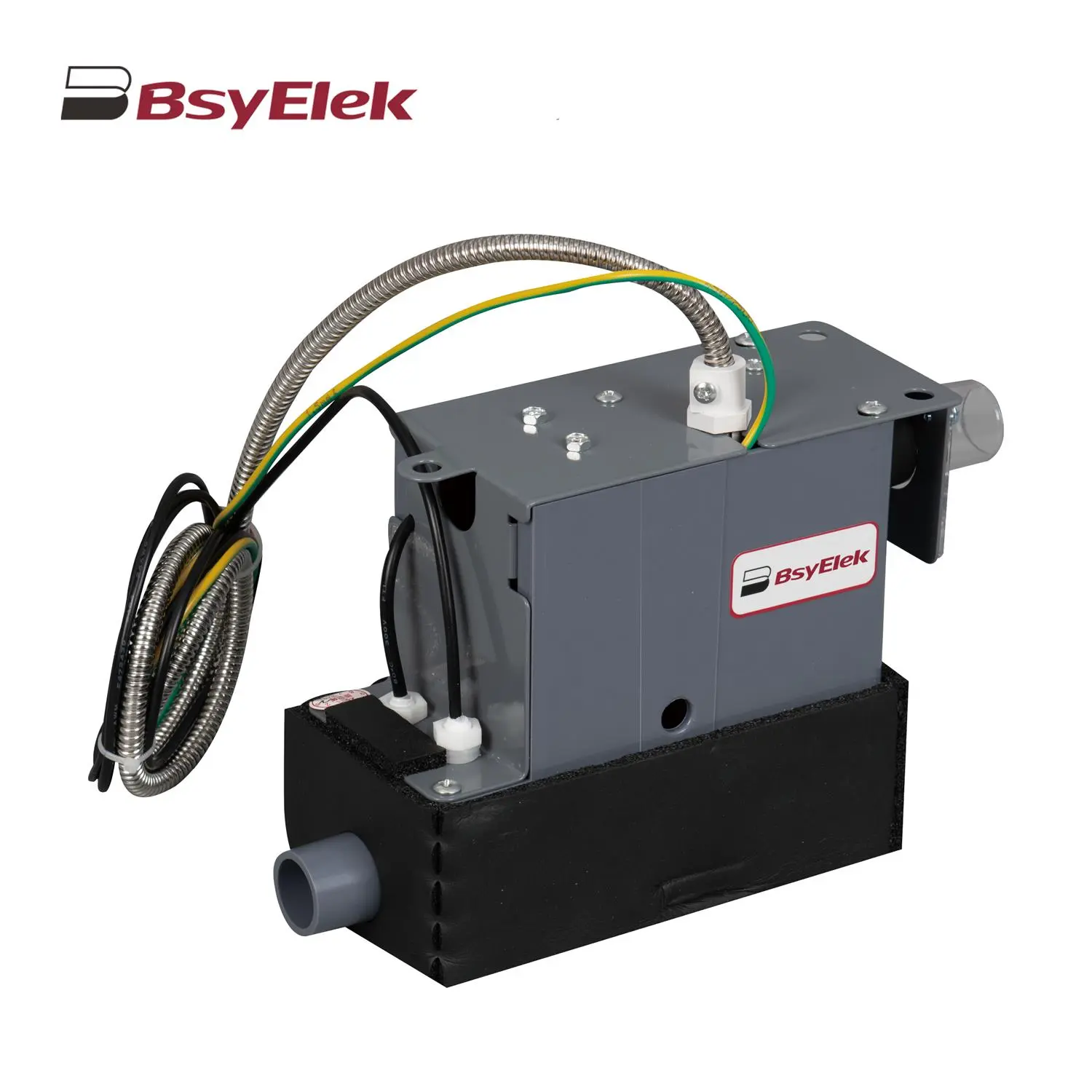

Condensate Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-24B/40B 10M Split Type Drainage Pump

BY-24B/40B 10M Split Type Drainage Pump

BY-100L 2M Drainage Pump of Air Conditioner

BY-100L 2M Drainage Pump of Air Conditioner

BY-360L 6M Large Displacement Drainage Pump

BY-360L 6M Large Displacement Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

News

Top Blog

Company News

Industry Dynamics

What is a miniature circuit breaker (MCB)?

PG Series Waterproof Cable Glands with Washer for Harsh Environments

LWSF-125 125A Manual Changeover Switch ensures reliable power transfer

BYX2 AC contactor series: reliable power control for modern electrical systems

High-performance 1000V DC fuse holder optimizes solar photovoltaic system protection

BY07L-63 Residual Current Circuit Breaker Ensures Global Electrical Safety

BYQ5 ATS Isolation Dual Power Automatic Transfer Switch

BY19G 63A Manual Changeover Switch: Features and Benefits

Support

Blog

Contact Us

OF SD MX OF MCB Miniature Circuit Breaker Accessories

OF SD MX OF MCB Miniature Circuit Breaker Accessories BYG1-125 Main Switch MCB Isolator Switch

BYG1-125 Main Switch MCB Isolator Switch BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector

BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector

BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector BYX2 6-95A AC Contactor

BYX2 6-95A AC Contactor BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device

BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device

BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device

BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device BY19G 63A Manual Changeover Switch

BY19G 63A Manual Changeover Switch LWSF-125 125A Manual Changeover Switch

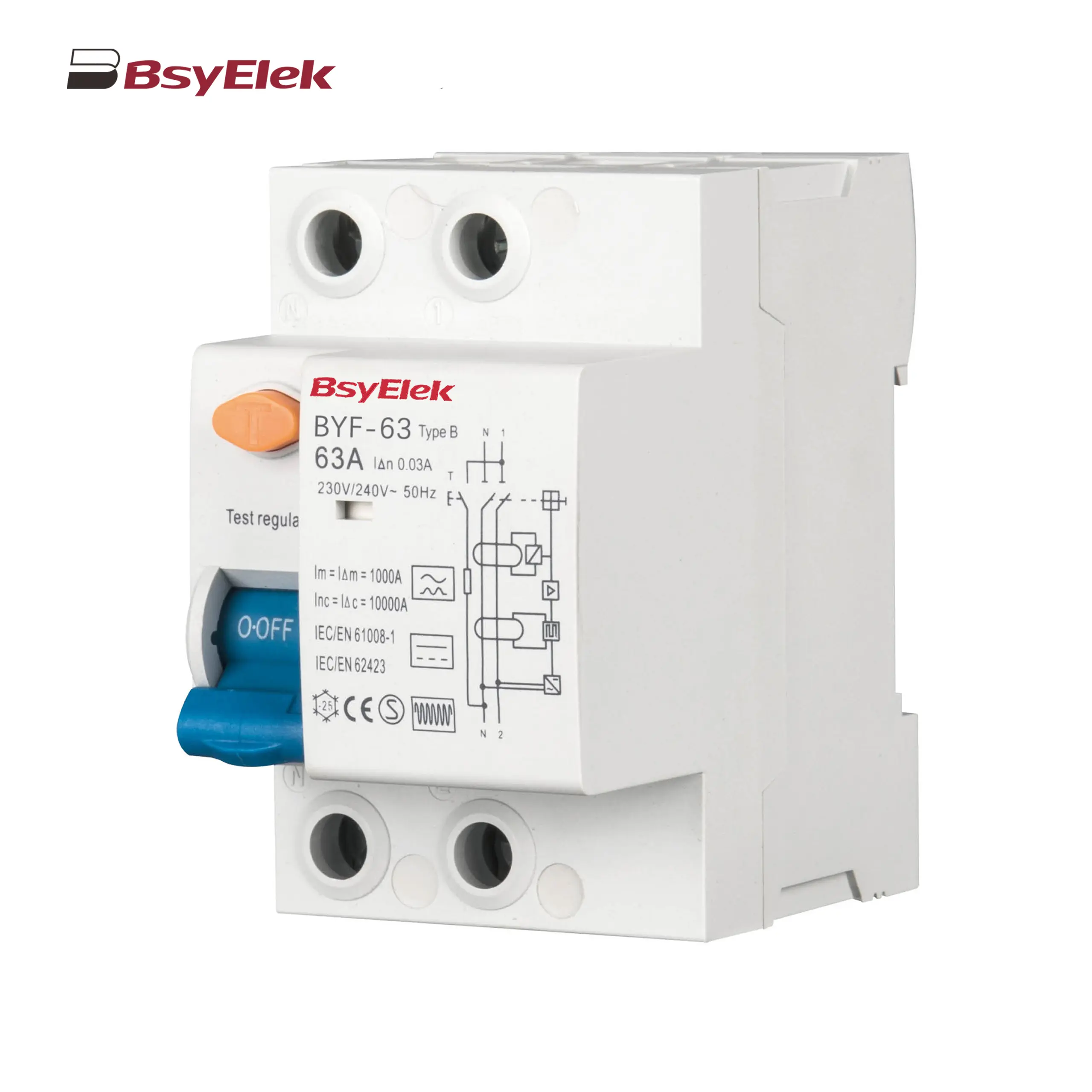

LWSF-125 125A Manual Changeover Switch BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device

BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device

BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device

BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link

BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link

BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link BYPV-ELR2 PV Isolator Switch with Enclosed Version

BYPV-ELR2 PV Isolator Switch with Enclosed Version BYPV-ELR1 PV Isolator Switch with Enclosed Version

BYPV-ELR1 PV Isolator Switch with Enclosed Version BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle

BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle BYPV-NL1 PV Isolator Switch with Lever Handle

BYPV-NL1 PV Isolator Switch with Lever Handle BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle

BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle PV-BY-01 30A/50A 1000V Photovoltaic Connector

PV-BY-01 30A/50A 1000V Photovoltaic Connector PV-BY-02 30A/50A 1500V Photovoltaic Connector

PV-BY-02 30A/50A 1500V Photovoltaic Connector PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector

PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector PV-BY-F01 30A 1500V Diode/Fuse Type Connector

PV-BY-F01 30A 1500V Diode/Fuse Type Connector PV-BY-T 50A 1500V T Type Branch Connector

PV-BY-T 50A 1500V T Type Branch Connector PV-BY-Y 30A 1500V Y Type Branch Connector

PV-BY-Y 30A 1500V Y Type Branch Connector PG Waterproof Cable Gland with Washer

PG Waterproof Cable Gland with Washer Photovoltaic Cable

Photovoltaic Cable HD11N Photovoltaic Knife Switch

HD11N Photovoltaic Knife Switch BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker

BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker

BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker BYM1E MCCB Electronic Type Molded Case Circuit Breaker

BYM1E MCCB Electronic Type Molded Case Circuit Breaker BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker

BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker BYW1 ACB Intelligent Universal Air Circuit Breaker

BYW1 ACB Intelligent Universal Air Circuit Breaker BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch

BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch Stainless Steel Hinge Type Electrical Box

Stainless Steel Hinge Type Electrical Box HA Waterproof Distribution Box

HA Waterproof Distribution Box HT Waterproof Distribution Box

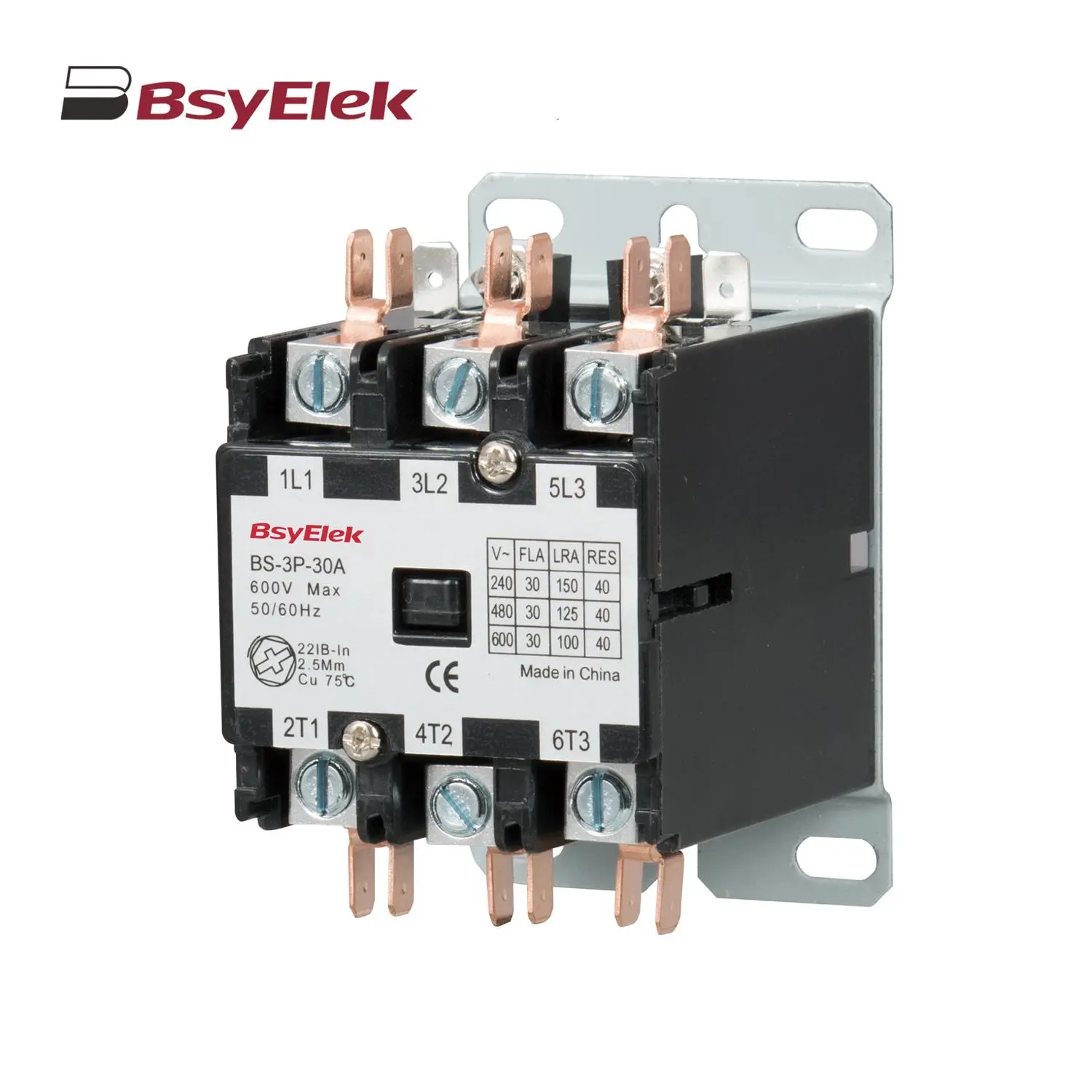

HT Waterproof Distribution Box BS Definite Purpose Magnetic AC Contactor

BS Definite Purpose Magnetic AC Contactor