How to Ensure Longevity and Safety with Waterproof Distribution Boxes: Insights & Best Practices

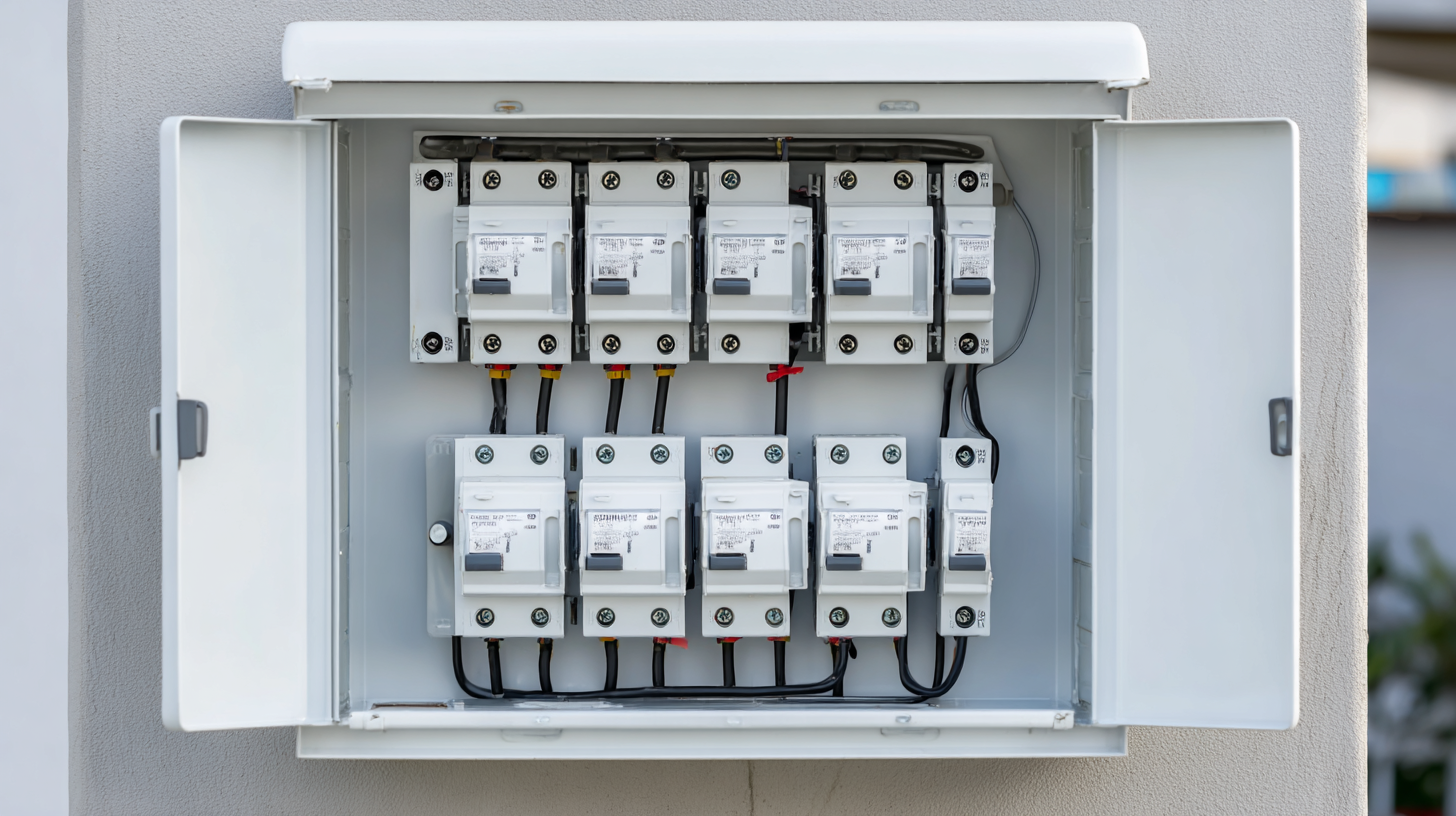

In today's rapidly evolving electrical infrastructure, ensuring the longevity and safety of power distribution systems is paramount. Waterproof Distribution Boxes have emerged as critical components in safeguarding electrical connections against environmental elements, thereby enhancing reliability.

According to a report by the National Electrical Manufacturers Association (NEMA), the failure of electrical distribution systems due to inadequate protection can lead to annual losses exceeding $2 billion, underscoring the importance of utilizing robust solutions like waterproof distribution boxes. These enclosures not only provide protection against water ingress but also help mitigate risks related to corrosion, short circuits, and electrical failures.

As industries increasingly shift towards automation and outdoor installations, understanding the best practices for implementing waterproof distribution boxes is essential for maintaining system integrity and ensuring operational safety. This guide aims to equip professionals with the insights necessary for optimizing the usage of waterproof distribution boxes in diverse applications.

Best Materials for Waterproof Distribution Boxes: Ensuring Durability and Performance

When it comes to ensuring longevity and safety in waterproof distribution boxes, selecting the right materials is paramount. According to a study by the International Electrotechnical Commission, materials that withstand harsh environmental conditions can significantly reduce the failure rates of electrical components housed in these boxes. For instance, materials such as polycarbonate and fiberglass-reinforced polyester provide excellent impact resistance and UV stability, making them ideal for outdoor applications where exposure to the elements is a constant threat.

Moreover, the use of thermoplastic elastomers (TPE) for seals and gaskets has been shown to enhance the waterproofing capabilities of distribution boxes. Research from the Waterproofing Industry Association indicates that TPE seals can maintain their integrity over a wider range of temperatures compared to traditional rubber seals, thus minimizing the risk of leaks. Incorporating corrosion-resistant metals, such as stainless steel or aluminum with protective coatings, further ensures the durability of distribution boxes against humidity and saltwater exposure. These material choices not only contribute to optimal performance but also extend the operational lifespan of the equipment, leading to reduced maintenance costs over time.

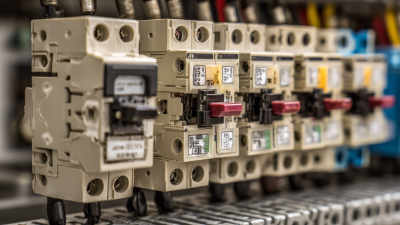

Key Features to Look for in High-Quality Waterproof Distribution Boxes

When selecting high-quality waterproof distribution boxes, there are several

key features that should be prioritized to ensure both longevity and safety, especially in

challenging weather conditions. First and foremost, look for robust materials that are designed to

withstand exposure to water and extreme temperatures. Materials like high-grade plastic or aluminum

with corrosion-resistant coatings can significantly enhance durability, reducing the likelihood of damage

during heavy rain or storms.

Additionally, proper sealing mechanisms are critical for water resistance.

High-quality distribution boxes often feature advanced gaskets and seals

that create an airtight barrier, preventing moisture ingress. It's also important to consider the design,

ensuring that drainage systems are incorporated to channel away any water that might

accumulate. This is especially relevant given recent weather events, such as heavy rainfall that has affected

various regions, where well-designed distribution boxes can help maintain power supply stability and prevent

electrical hazards. By focusing on these essential features, you can enhance the operational safety

and lifespan of waterproof distribution boxes in demanding environments.

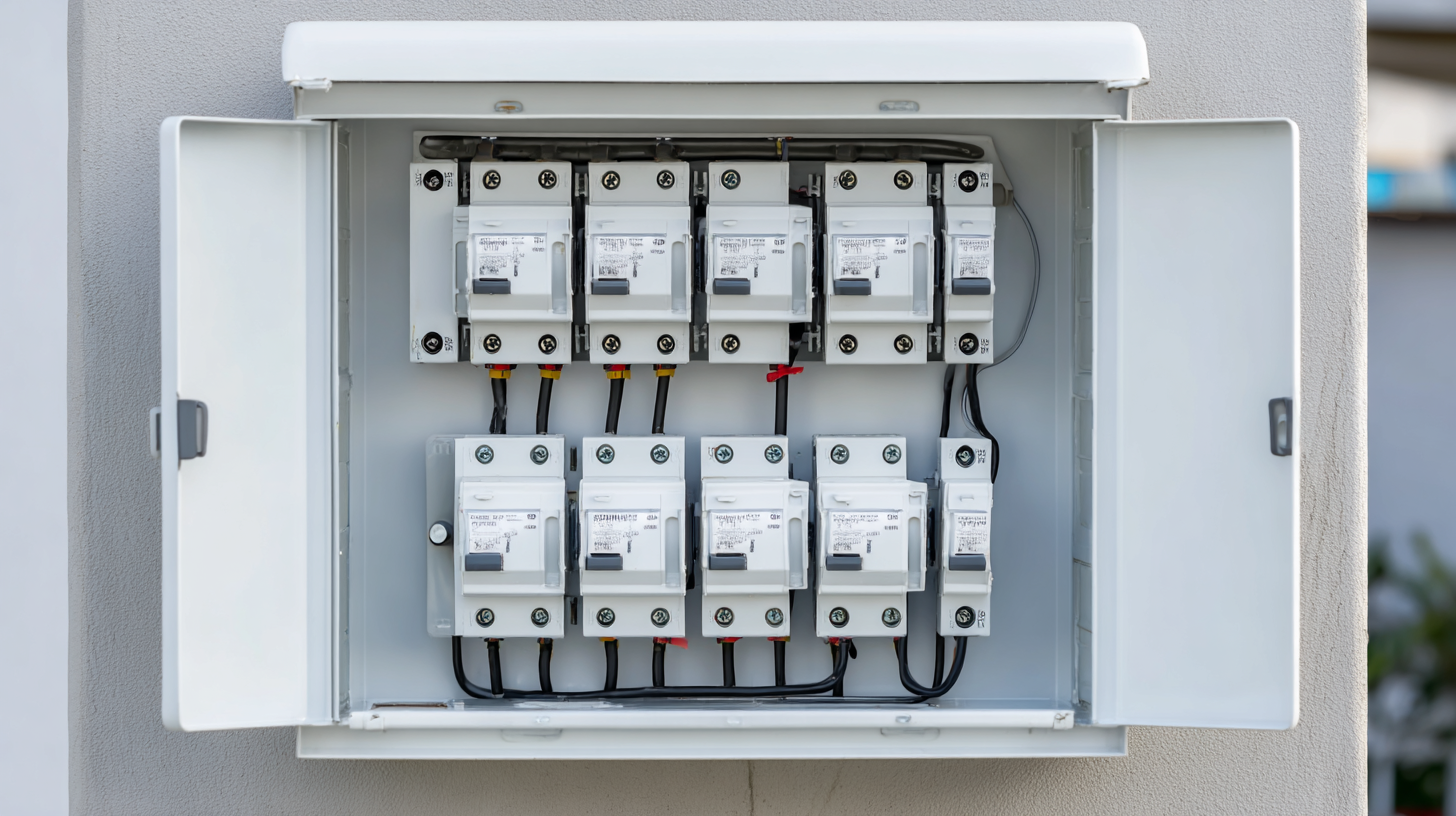

Essential Installation Guidelines for Maximizing Safety and Longevity

Installing waterproof distribution boxes correctly is crucial for maximizing safety and longevity. According to a recent industry report from the National Electrical Manufacturers Association (NEMA), improper installation can reduce the lifespan of electrical components by up to 40%. Ensuring a proper seal and selecting appropriate materials are foundational steps in safeguarding against moisture intrusion. Use high-quality gaskets and screws made of corrosion-resistant materials to maintain integrity over time.

Tips: Always check the manufacturer's guidelines for installation angles and weight limitations to enhance performance and minimize risks. Additionally, keeping the installation location dry and well-ventilated can significantly extend the life of the distribution box.

Regular maintenance cannot be overlooked; as per a survey by the International Electrotechnical Commission (IEC), 30% of system failures are attributed to insufficient inspections. Schedule periodic checks to ensure no water has infiltrated the box and that all connections remain secure. Small adjustments and prompt repairs can make a significant difference in durability, ensuring that your installation remains safe and efficient.

Maintenance Tips for Prolonging the Life of Waterproof Distribution Boxes

Waterproof distribution boxes are crucial for maintaining the integrity of electrical systems, especially as we move towards renewable energy solutions and smart city infrastructures. Regular maintenance plays a pivotal role in ensuring these boxes remain functional and safe over time. According to industry reports, waterproof junction boxes can extend their lifespan by up to 30% with proper care, which includes routine inspections and cleaning to remove debris and moisture accumulation. It's essential to check seals and gaskets for wear, as any compromise can lead to water ingress and potential failures.

In addition to physical inspections, adopting protective measures such as applying corrosion-resistant coatings can significantly enhance the durability of these distribution boxes. Research indicates that implementing such protective strategies can reduce maintenance costs by approximately 25%, as fewer replacements are needed. Furthermore, as the emphasis on sustainable infrastructure grows, ensuring the reliability of electrical systems is paramount. Investing in regular maintenance and following best practices can ultimately safeguard not just equipment longevity but also the safety of the overall electrical network.

In addition to physical inspections, adopting protective measures such as applying corrosion-resistant coatings can significantly enhance the durability of these distribution boxes. Research indicates that implementing such protective strategies can reduce maintenance costs by approximately 25%, as fewer replacements are needed. Furthermore, as the emphasis on sustainable infrastructure grows, ensuring the reliability of electrical systems is paramount. Investing in regular maintenance and following best practices can ultimately safeguard not just equipment longevity but also the safety of the overall electrical network.

Common Mistakes to Avoid When Using Waterproof Distribution Boxes

When utilizing waterproof distribution boxes, avoiding common mistakes can significantly enhance their longevity and ensure safety in any application. One major pitfall is improper installation. According to industry reports, nearly 30% of equipment failures can be attributed to inadequate mounting techniques or failure to follow installation guidelines. This can lead to water ingress, effectively nullifying the waterproofing features.

Tip: Always refer to the manufacturer’s installation instructions and utilize proper tools to ensure a secure and appropriate fit. Regular inspection and maintenance checks can also prevent long-term failures.

Another common mistake is overlooking environmental factors that contribute to wear and tear. For instance, exposure to extreme temperatures, UV rays, or corrosive substances can degrade materials over time. A study revealed that 40% of waterproof distribution boxes did not meet performance expectations due to insufficient material selection for their specific environmental conditions.

Tip: Before choosing a distribution box, consider the specific environment in which it will be installed and select materials that offer enhanced resistance to those conditions. Implementing these best practices ensures that your waterproof distribution boxes remain functional and safe, complying with industry standards and extending their service life.

Home

About Us

Products

Terminal Power Distribution Electric

AC Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

MCB Accessories

Main Switch

RCBO RCCB

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

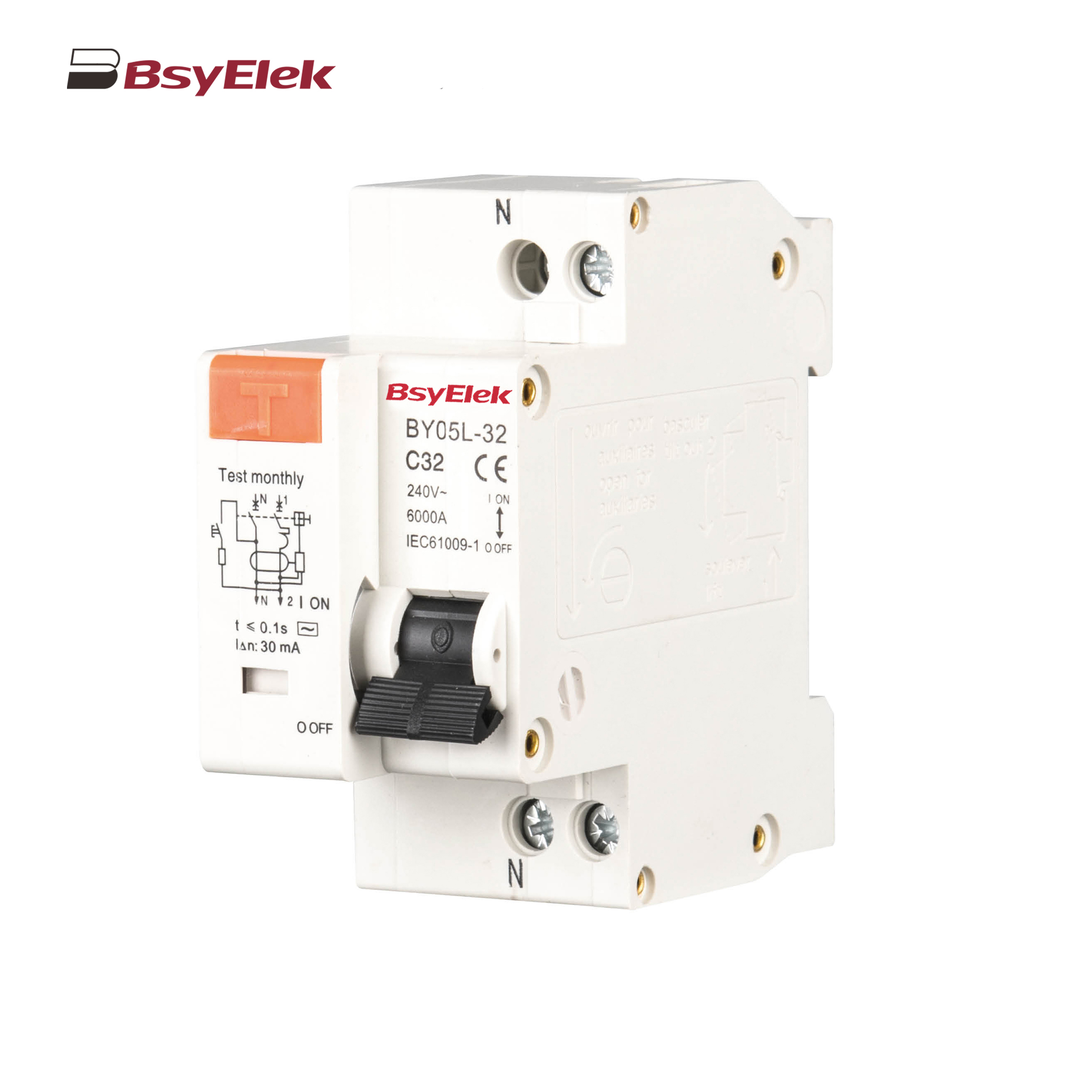

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

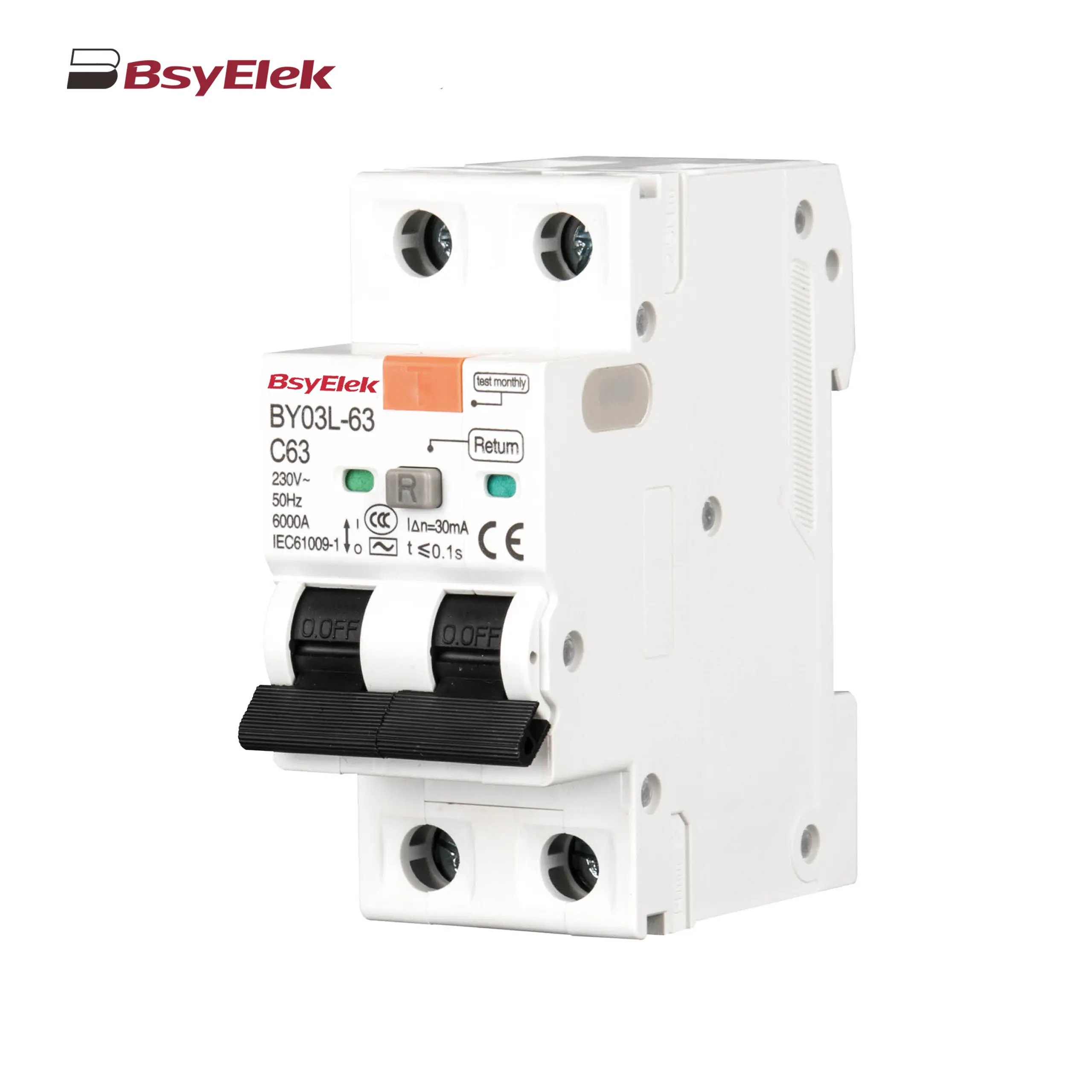

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

Resettable Overvoltage and Undervoltage Protector

AC Contactor

AC Surge Protective Device

Changeover Switch

Photovoltaic System Protection

DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

RCD

DC Surge Protective Device

DC Fuse

PV Isolator Switch

PV Connector

Cable Gland

PV Cable

PV Knife Switch

DC Molded Case Circuit Breaker

Industrial Power Distribution Electric

Distribution Box

Air Conditioning System

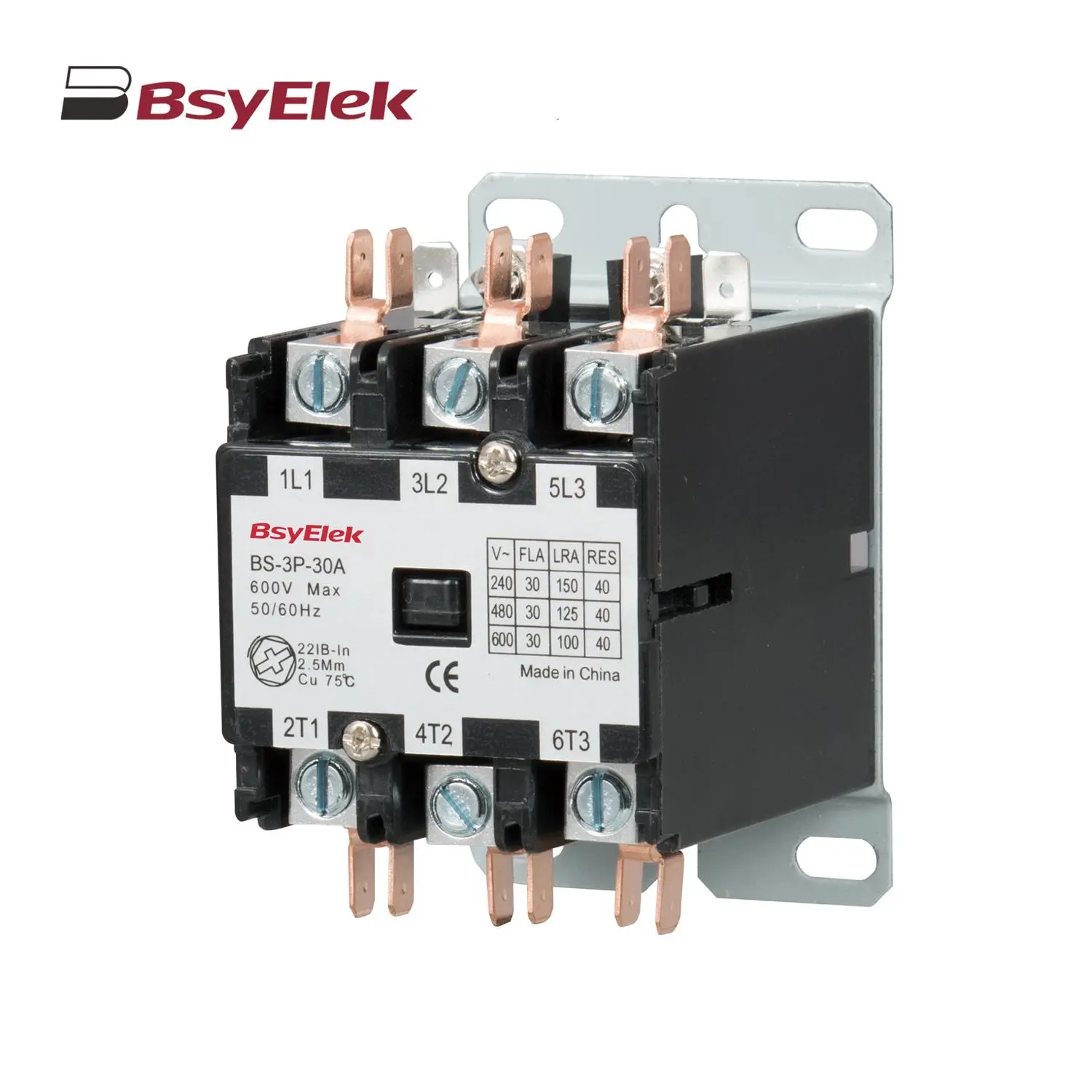

Definite Purpose Magnetic Contactor

Condensate Pump

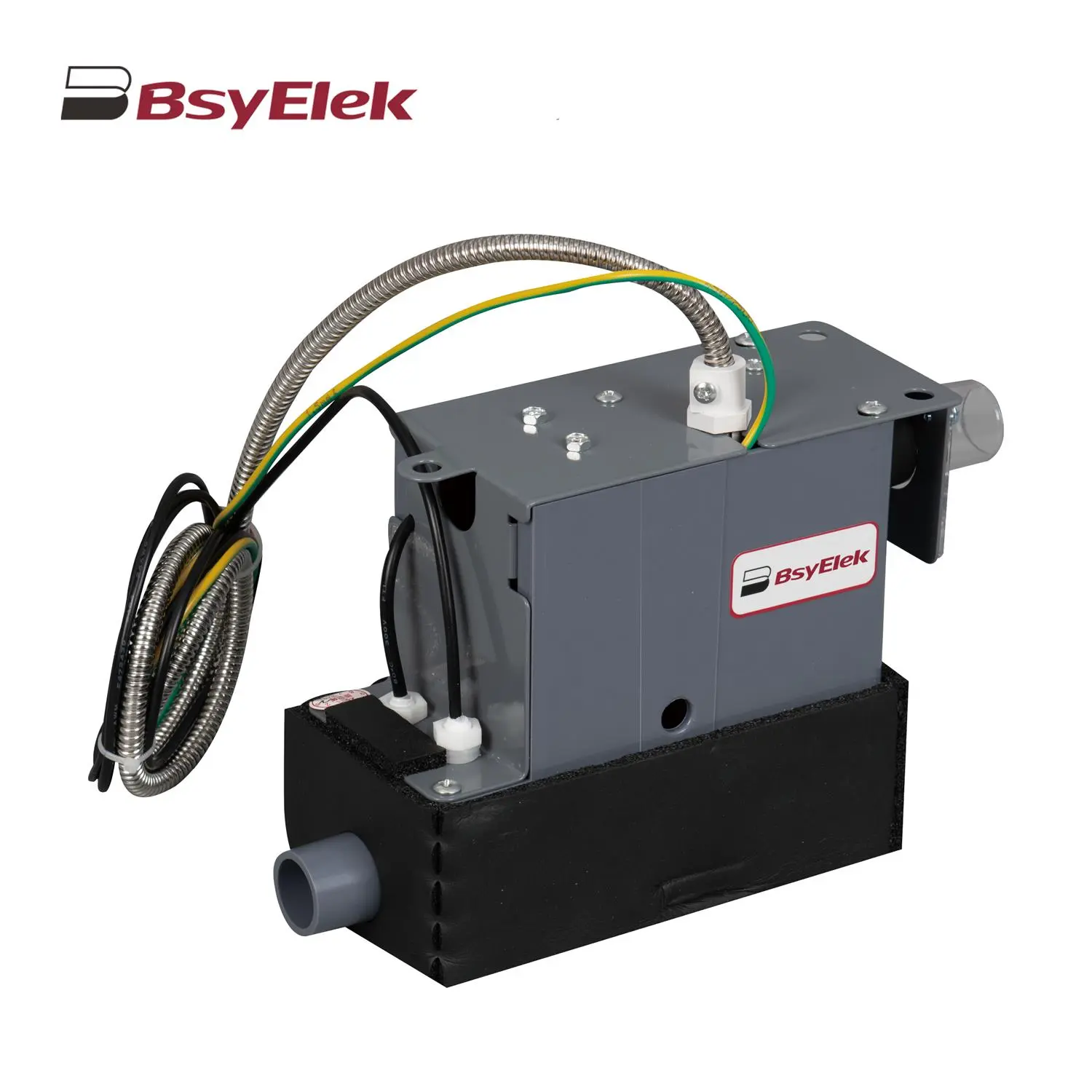

BY-5018 1.8M Engineering Drainage Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-24B/40B 10M Split Type Drainage Pump

BY-24B/40B 10M Split Type Drainage Pump

BY-100L 2M Drainage Pump of Air Conditioner

BY-100L 2M Drainage Pump of Air Conditioner

BY-360L 6M Large Displacement Drainage Pump

BY-360L 6M Large Displacement Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

News

Top Blog

Company News

Industry Dynamics

What is a miniature circuit breaker (MCB)?

PG Series Waterproof Cable Glands with Washer for Harsh Environments

LWSF-125 125A Manual Changeover Switch ensures reliable power transfer

BYX2 AC contactor series: reliable power control for modern electrical systems

High-performance 1000V DC fuse holder optimizes solar photovoltaic system protection

BY07L-63 Residual Current Circuit Breaker Ensures Global Electrical Safety

BYQ5 ATS Isolation Dual Power Automatic Transfer Switch

BY19G 63A Manual Changeover Switch: Features and Benefits

Support

Blog

Contact Us

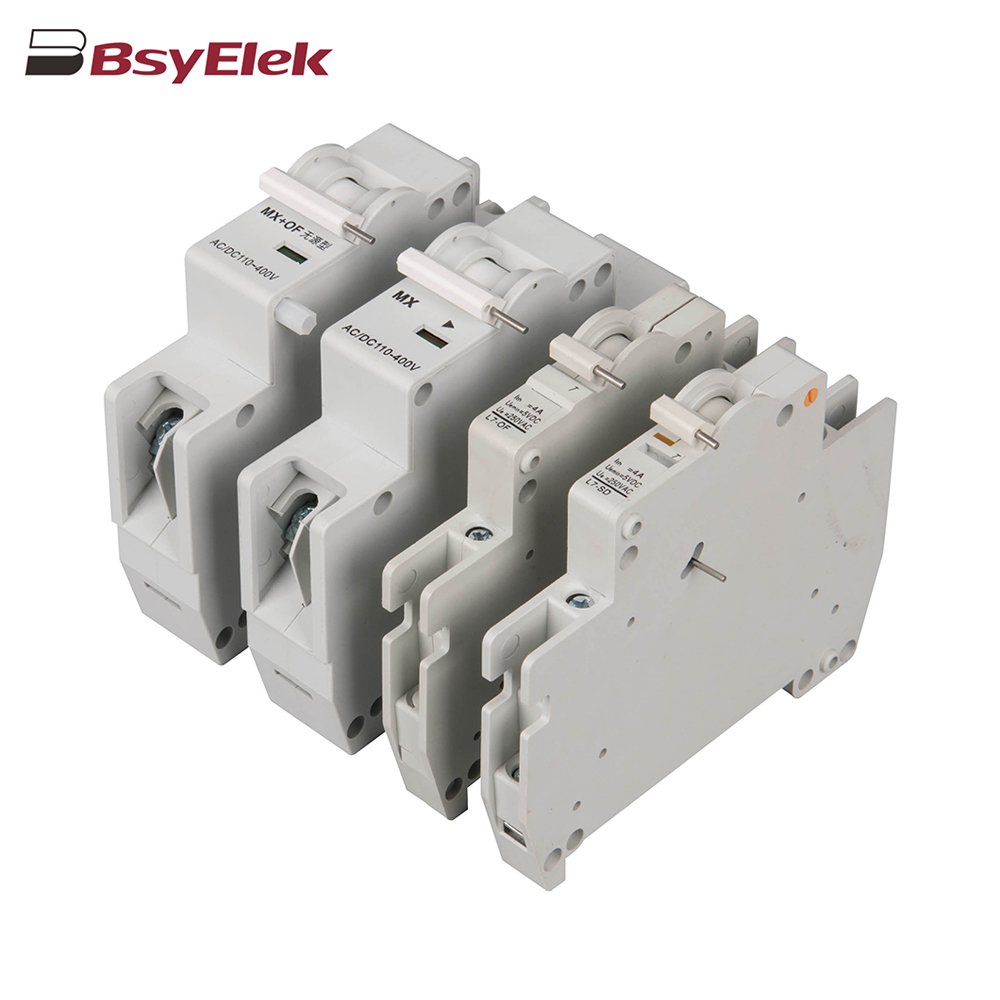

OF SD MX OF MCB Miniature Circuit Breaker Accessories

OF SD MX OF MCB Miniature Circuit Breaker Accessories BYG1-125 Main Switch MCB Isolator Switch

BYG1-125 Main Switch MCB Isolator Switch BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector

BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector

BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector BYX2 6-95A AC Contactor

BYX2 6-95A AC Contactor BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device

BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device

BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device

BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device BY19G 63A Manual Changeover Switch

BY19G 63A Manual Changeover Switch LWSF-125 125A Manual Changeover Switch

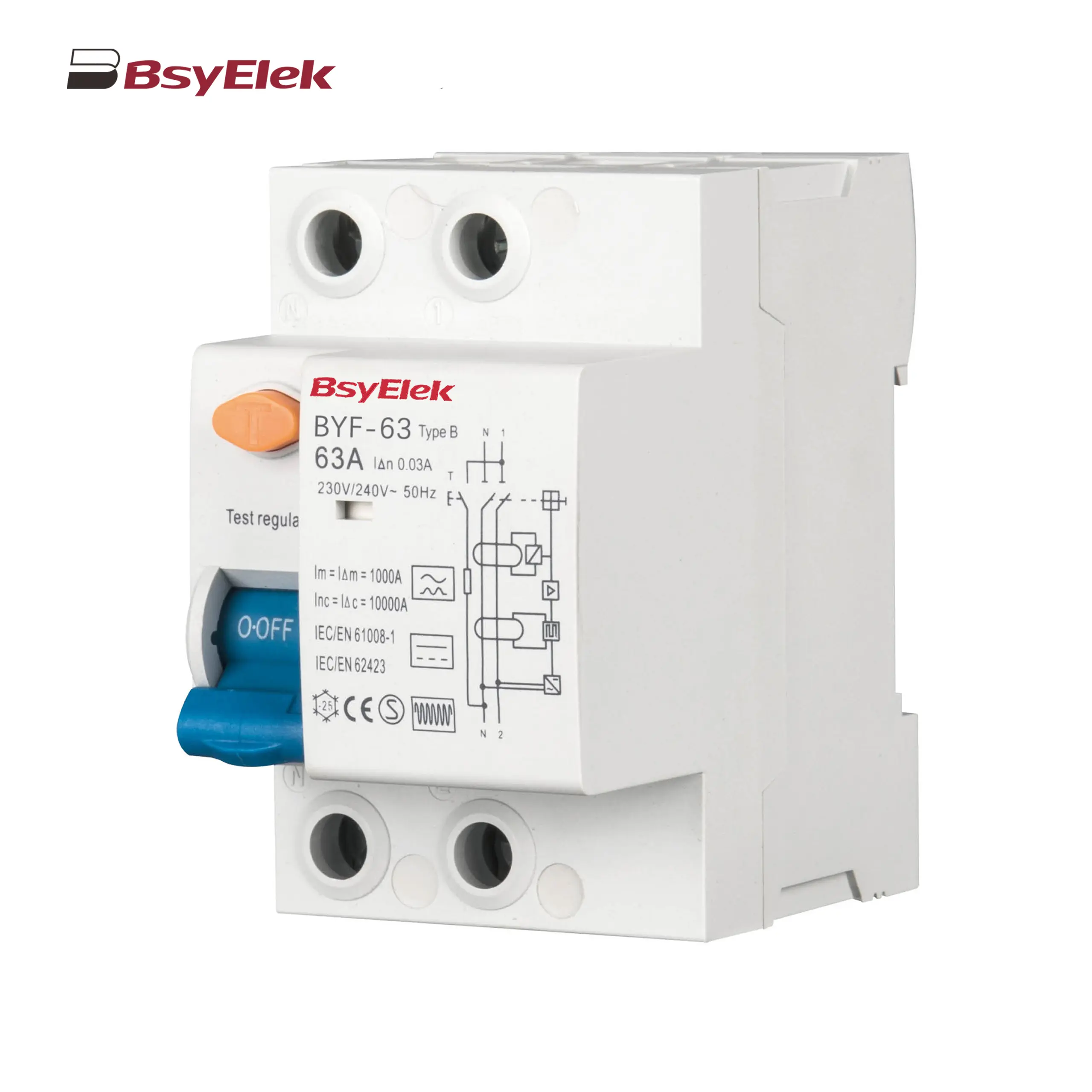

LWSF-125 125A Manual Changeover Switch BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device

BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device

BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device

BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link

BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link

BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link BYPV-ELR2 PV Isolator Switch with Enclosed Version

BYPV-ELR2 PV Isolator Switch with Enclosed Version BYPV-ELR1 PV Isolator Switch with Enclosed Version

BYPV-ELR1 PV Isolator Switch with Enclosed Version BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle

BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle BYPV-NL1 PV Isolator Switch with Lever Handle

BYPV-NL1 PV Isolator Switch with Lever Handle BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle

BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle PV-BY-01 30A/50A 1000V Photovoltaic Connector

PV-BY-01 30A/50A 1000V Photovoltaic Connector PV-BY-02 30A/50A 1500V Photovoltaic Connector

PV-BY-02 30A/50A 1500V Photovoltaic Connector PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector

PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector PV-BY-F01 30A 1500V Diode/Fuse Type Connector

PV-BY-F01 30A 1500V Diode/Fuse Type Connector PV-BY-T 50A 1500V T Type Branch Connector

PV-BY-T 50A 1500V T Type Branch Connector PV-BY-Y 30A 1500V Y Type Branch Connector

PV-BY-Y 30A 1500V Y Type Branch Connector PG Waterproof Cable Gland with Washer

PG Waterproof Cable Gland with Washer Photovoltaic Cable

Photovoltaic Cable HD11N Photovoltaic Knife Switch

HD11N Photovoltaic Knife Switch BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker

BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker

BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker BYM1E MCCB Electronic Type Molded Case Circuit Breaker

BYM1E MCCB Electronic Type Molded Case Circuit Breaker BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker

BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker BYW1 ACB Intelligent Universal Air Circuit Breaker

BYW1 ACB Intelligent Universal Air Circuit Breaker BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch

BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch Stainless Steel Hinge Type Electrical Box

Stainless Steel Hinge Type Electrical Box HA Waterproof Distribution Box

HA Waterproof Distribution Box HT Waterproof Distribution Box

HT Waterproof Distribution Box BS Definite Purpose Magnetic AC Contactor

BS Definite Purpose Magnetic AC Contactor

In addition to physical inspections, adopting protective measures such as applying corrosion-resistant coatings can significantly enhance the durability of these distribution boxes. Research indicates that implementing such protective strategies can reduce maintenance costs by approximately

In addition to physical inspections, adopting protective measures such as applying corrosion-resistant coatings can significantly enhance the durability of these distribution boxes. Research indicates that implementing such protective strategies can reduce maintenance costs by approximately