Understanding the Importance of Disconnect Switches in Electrical Safety

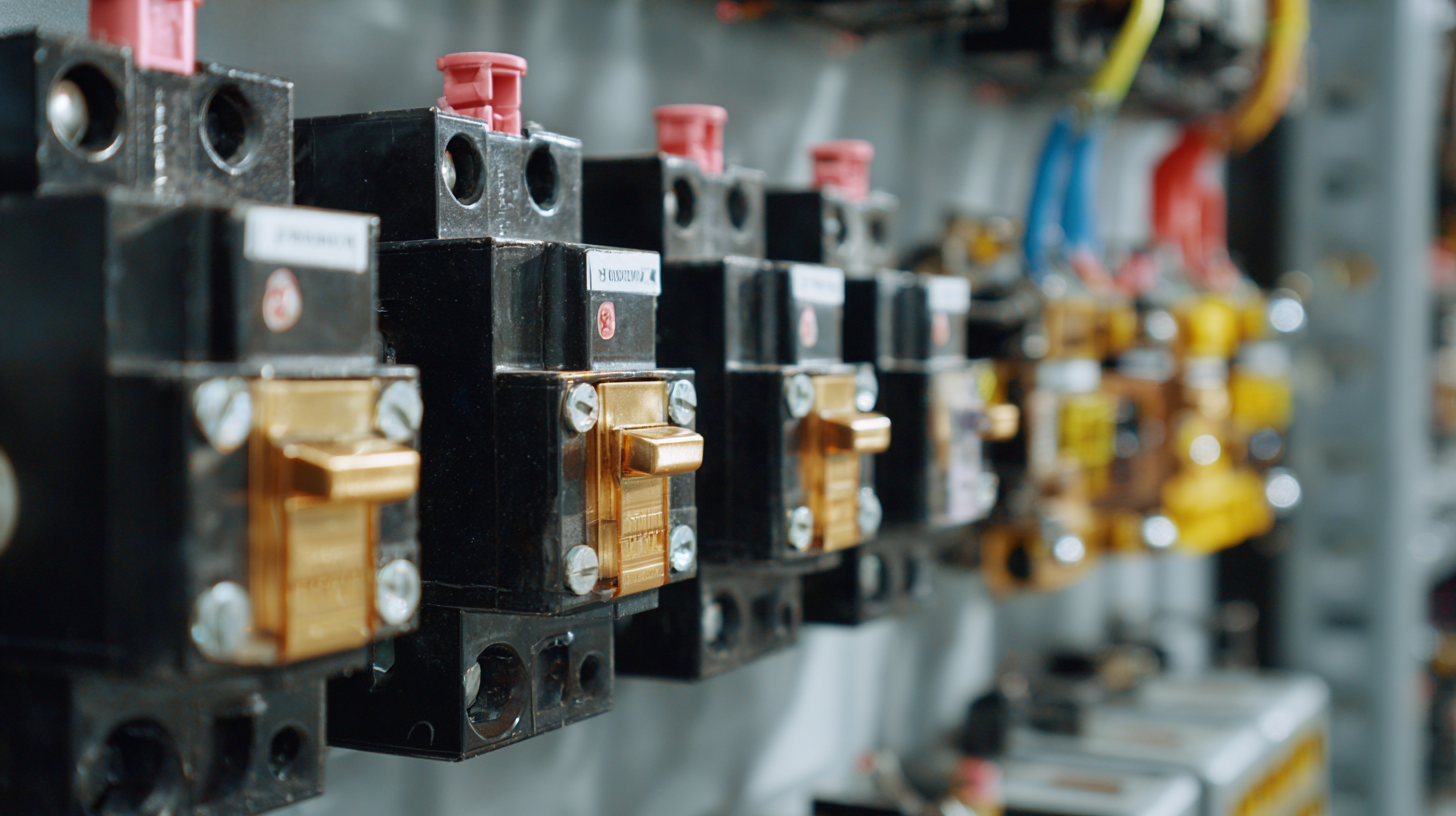

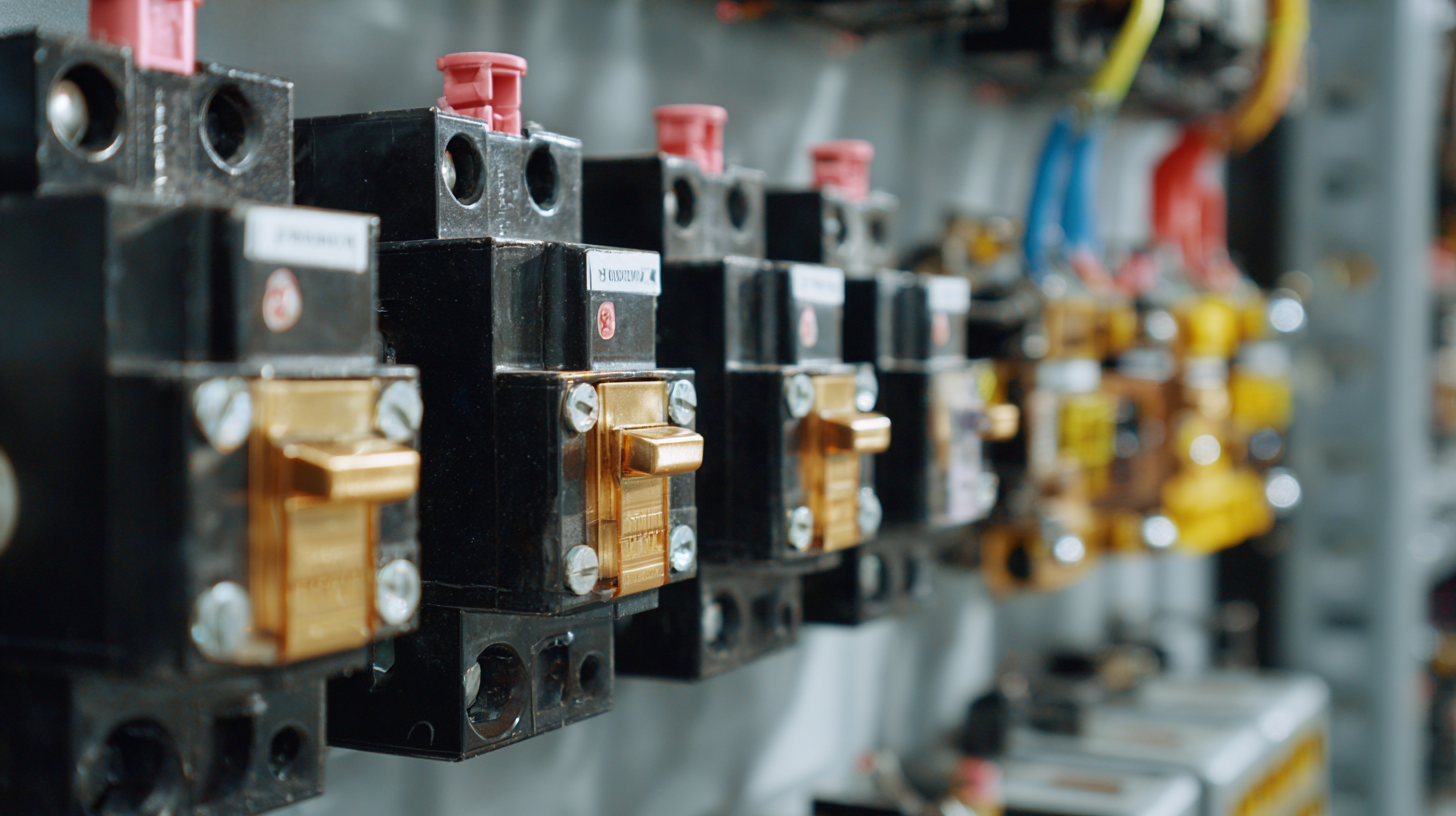

The significance of Disconnect Switches in ensuring electrical safety cannot be overstated, especially in industrial settings where the risks are compounded by high voltage operations.

According to a report by the National Fire Protection Association (NFPA), electrical failures are attributed to nearly 10% of all workplace fires, underscoring the necessity of reliable safety mechanisms such as Disconnect Switches.

These devices serve a critical role by providing a reliable means to isolate electrical circuits during maintenance or emergencies, thus preventing accidental electrocution and equipment damage.

Furthermore, the International Electrotechnical Commission highlights that improper use of electrical systems can lead to catastrophic failures, prompting the implementation of standards that recommend the use of Disconnect Switches in accordance with safety protocols.

By prioritizing the integration of Disconnect Switches, organizations can proactively mitigate risks, enhance worker safety, and comply with industry regulations, ultimately safeguarding both personnel and assets.

How to Identify the Right Disconnect Switch for Your Electrical System

When selecting a disconnect switch for your electrical system, it is crucial to consider several key factors to ensure both safety and efficiency. According to a report by the NEMA, approximately 30% of electrical incidents can be traced back to malfunctioning or improperly used disconnect switches. Therefore, understanding the specific requirements of your system is essential in preventing hazards.

When selecting a disconnect switch for your electrical system, it is crucial to consider several key factors to ensure both safety and efficiency. According to a report by the NEMA, approximately 30% of electrical incidents can be traced back to malfunctioning or improperly used disconnect switches. Therefore, understanding the specific requirements of your system is essential in preventing hazards.

Start by assessing the voltage and current ratings of your application. For instance, the IEEE Standard 241-2022 recommends that disconnect switches should be rated for at least 125% of the load current to accommodate inrush currents and prevent overheating. Additionally, it is essential to consider the environmental conditions where the switch will be installed. NEMA offers classifications for enclosures, indicating resistance to dust, moisture, and corrosion, which can significantly impact the longevity and reliability of the switch.

Furthermore, ensure that the switch complies with industry standards, such as UL 1008 for automatic transfer switches or IEC 60947-3 for low-voltage switchgear. A study by the Electrical Safety Foundation International (ESFI) indicates that using certified equipment lowers the risk of electrical failures by up to 50%. By taking these factors into account, you can identify a disconnect switch that not only suits your electrical system but also enhances overall safety and operational reliability.

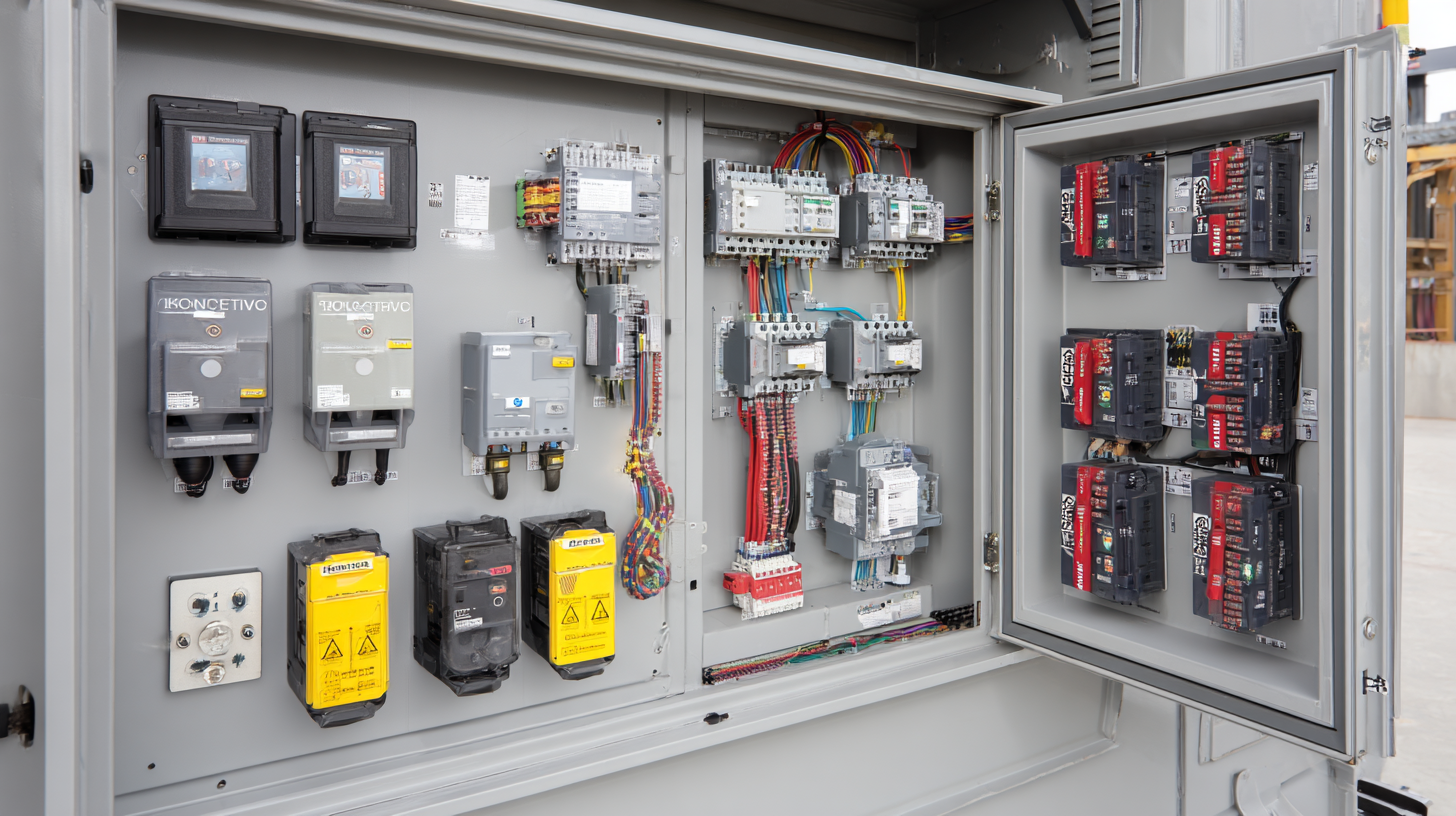

How to Ensure Proper Installation of Disconnect Switches for Maximum Safety

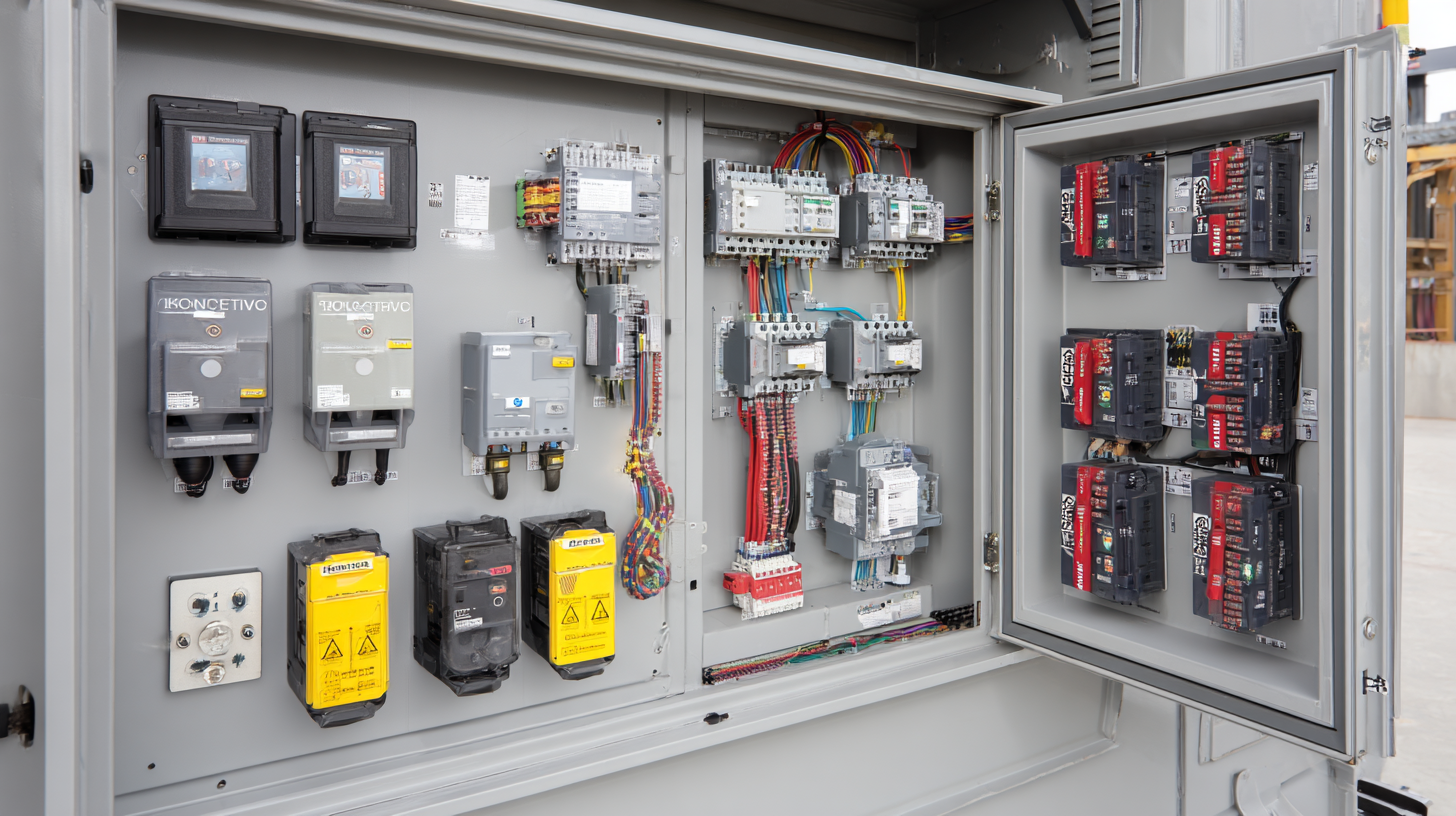

Proper installation of disconnect switches is crucial for enhancing electrical safety in industrial environments. Disconnect switches serve as critical components that allow for the safe isolation of electrical circuits, preventing potential hazards during maintenance and troubleshooting. The global disconnect switch market is witnessing significant growth, with a projected increase from $4.99 billion in 2025 to $7.66 billion by 2030. This trend underscores the importance of these devices in ensuring the reliability of electrical systems.

To maximize safety, it is essential that disconnect switches are installed correctly. Key considerations include ensuring that the switches are easily accessible and clearly marked to facilitate quick operation in emergencies. Additionally, regular maintenance checks should be conducted to ensure that the switches function properly and that connections remain secure. According to industry reports, the non-fused disconnect switch market is expected to expand from $9.80 billion in 2025 to $14.61 billion by 2032, highlighting the increasing recognition of their role in maintaining safe electrical practices. Implementing comprehensive installation guidelines can significantly reduce the risk of electrical accidents, ensuring a safer working environment.

Understanding the Importance of Disconnect Switches in Electrical Safety

This chart illustrates the correlation between the proper installation of disconnect switches and the reduction of electrical accidents over the years. It presents data on the percentage of incidents reported relative to the installation practices, highlighting the crucial role disconnect switches play in safety standards.

How to Perform Regular Maintenance on Disconnect Switches to Prevent Failures

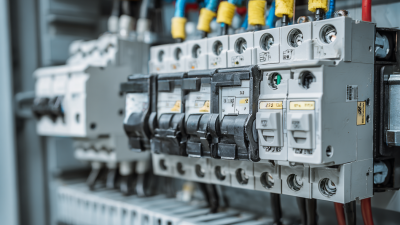

Regular maintenance of disconnect switches is crucial in ensuring the safety and reliability of electrical systems. Disconnect switches serve as a vital safety mechanism, allowing users to isolate electrical circuits for maintenance or emergencies. To prevent failures, a systematic approach to maintenance is essential. This includes routine inspections that check for signs of wear and corrosion, which can impact the performance of the switch. Visual inspections should be complemented by functional tests to confirm that the switches operate effectively under load.

In addition to inspections, it is important to clean the contacts and enclosures of disconnect switches regularly. Accumulation of dust and dirt can lead to overheating and operational failures. Lubricating moving parts can also ensure smooth operation, reducing the risk of malfunction during critical moments. Furthermore, maintaining a log of maintenance activities can help track the condition of each switch, making it easier to identify when replacement or more extensive repairs are needed. By adhering to these maintenance practices, organizations can greatly improve the safety and longevity of their electrical systems.

How to Understand the Role of Disconnect Switches in Equipment Lockout/Tagout Procedures

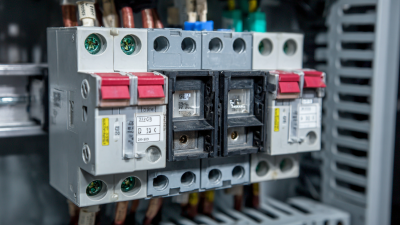

Disconnect switches play a critical role in ensuring safety during maintenance and repair of electrical equipment. Their primary function is to isolate electrical circuits from the power supply, thereby protecting workers from electric shock and equipment damage. In the context of Lockout/Tagout (LOTO) procedures, the implementation of disconnect switches becomes even more vital. By securely disconnecting power sources, these switches prevent accidental re-energization of equipment, ensuring a safe working environment for all personnel involved.

When employing disconnect switches in LOTO procedures, it's crucial to follow several key tips. First, always verify the operational status of the disconnect switch prior to work. Use appropriate testing equipment to confirm that the circuit is de-energized. Second, ensure that the switch is physically locked out and tagged by authorized personnel. This provides clear communication and prevents unauthorized access. Lastly, maintain clear documentation of the procedures, including personnel involved and equipment affected, to enhance accountability and improve safety protocols.

Understanding the interplay between disconnect switches and LOTO procedures is essential in minimizing risks. Workers must be trained to recognize the importance of these switches and to adhere strictly to safety guidelines. Implementing a culture of safety awareness not only protects individuals but also enhances overall workplace efficiency.

How to Educate Your Team on the Importance of Disconnect Switches in Electrical Safety

In today's industrial landscape, electrical safety is paramount, and educating your team on the significance of disconnect switches plays a crucial role in maintaining a safe working environment. Disconnect switches allow for the safe isolation of electrical circuits, particularly during maintenance and emergency situations. According to the National Fire Protection Association (NFPA), electrical failures accounted for over 9% of all reported fires in the United States in 2018, underscoring the need for proper safety measures. Implementing comprehensive training programs that emphasize the use and importance of disconnect switches can drastically reduce the risk of electrical hazards.

To effectively educate your team, start by incorporating hands-on training sessions that illustrate the correct operation of disconnect switches and their vital role in electrical safety. A report from the Electric Power Research Institute (EPRI) indicates that organizations with robust training programs can decrease electrical incidents by up to 50%. Additionally, consider using real-life case studies demonstrating the consequences of neglecting disconnect switch protocols. By fostering a culture of safety that prioritizes understanding and using disconnect switches, you can empower your team to take proactive measures, ultimately enhancing workplace safety and compliance with regulations.

Understanding the Importance of Disconnect Switches in Electrical Safety

| Dimension |

Description |

Importance |

Best Practices |

| Functionality |

Disconnects an electrical circuit quickly for maintenance and safety. |

Prevents accidental energization during maintenance. |

Regular training on appropriate usage and prompt labeling. |

| Types |

Manual, automatic, and emergency disconnect switches. |

Choosing the right type reduces risks in various environments. |

Assess the environment and load requirements regularly. |

| Regulations |

Standards set by agencies like OSHA and NEC. |

Compliance with regulations ensures safety and legality. |

Stay updated on regulatory changes and conduct audits. |

| Inspection |

Regular checks for wear, corrosion, and functionality. |

Identifying issues before they become hazards. |

Implement a scheduled inspection program. |

Home

About Us

Products

Terminal Power Distribution Electric

AC Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

MCB Accessories

Main Switch

RCBO RCCB

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

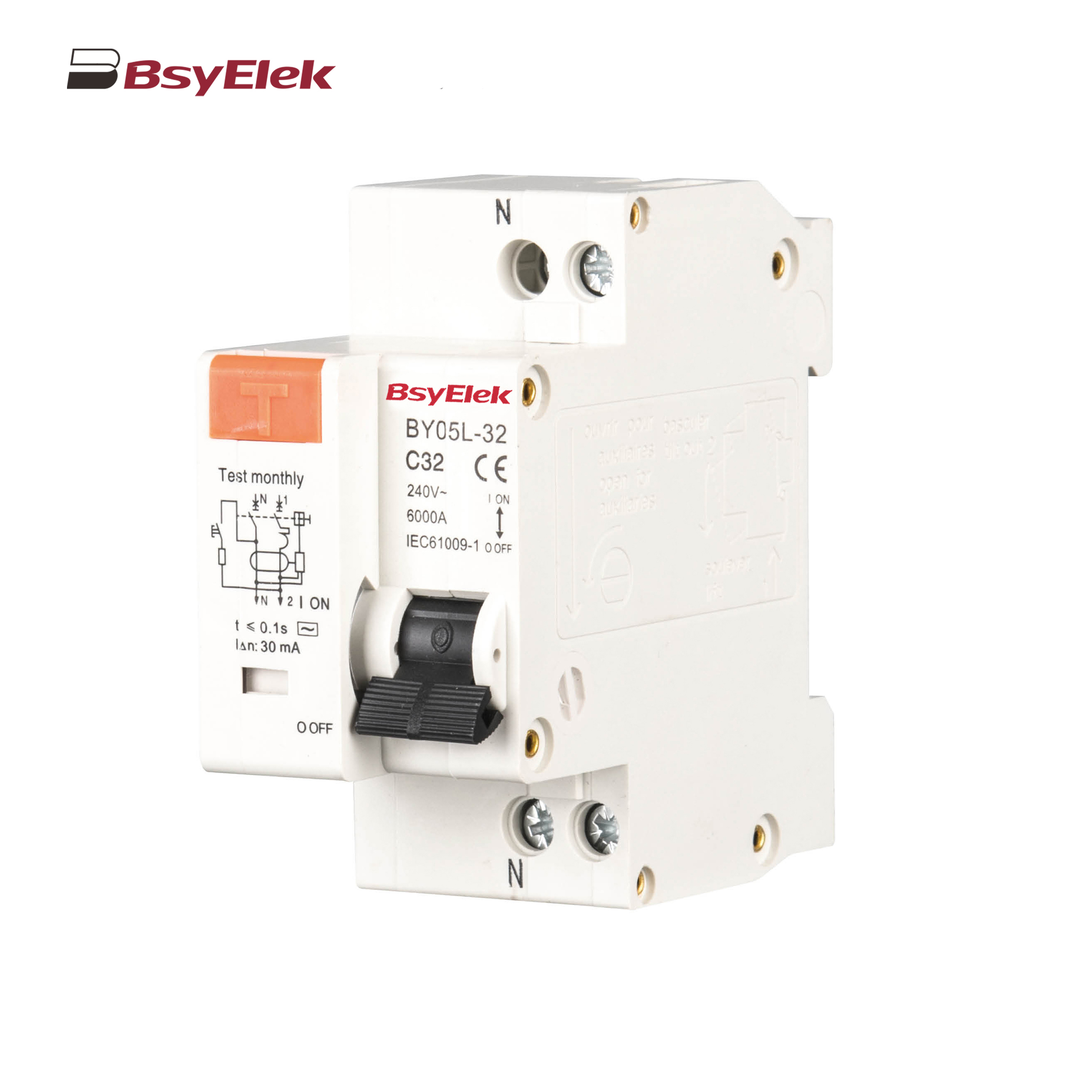

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

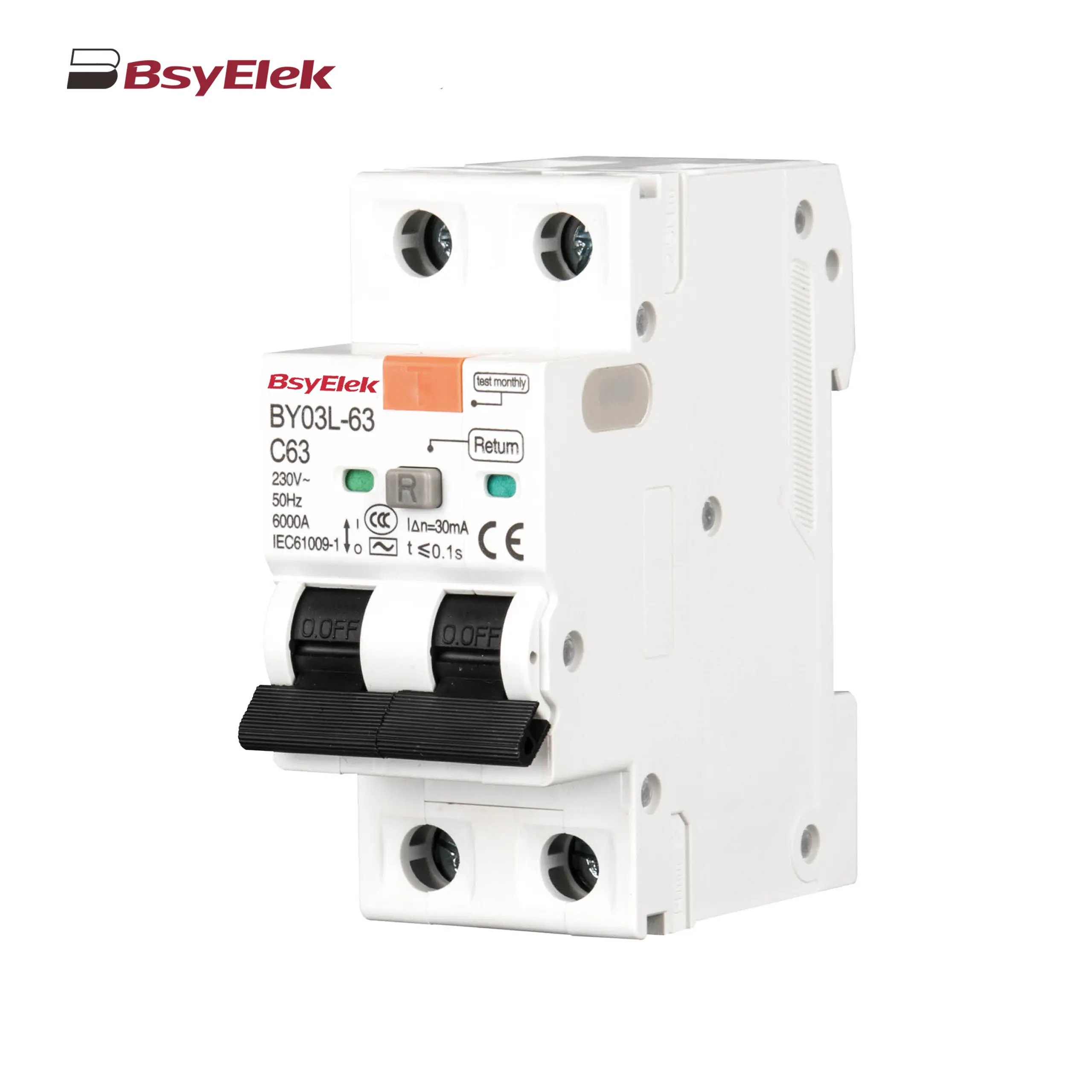

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

Resettable Overvoltage and Undervoltage Protector

AC Contactor

AC Surge Protective Device

Changeover Switch

Photovoltaic System Protection

DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

RCD

DC Surge Protective Device

DC Fuse

PV Isolator Switch

PV Connector

Cable Gland

PV Cable

PV Knife Switch

DC Molded Case Circuit Breaker

Industrial Power Distribution Electric

Distribution Box

Air Conditioning System

Definite Purpose Magnetic Contactor

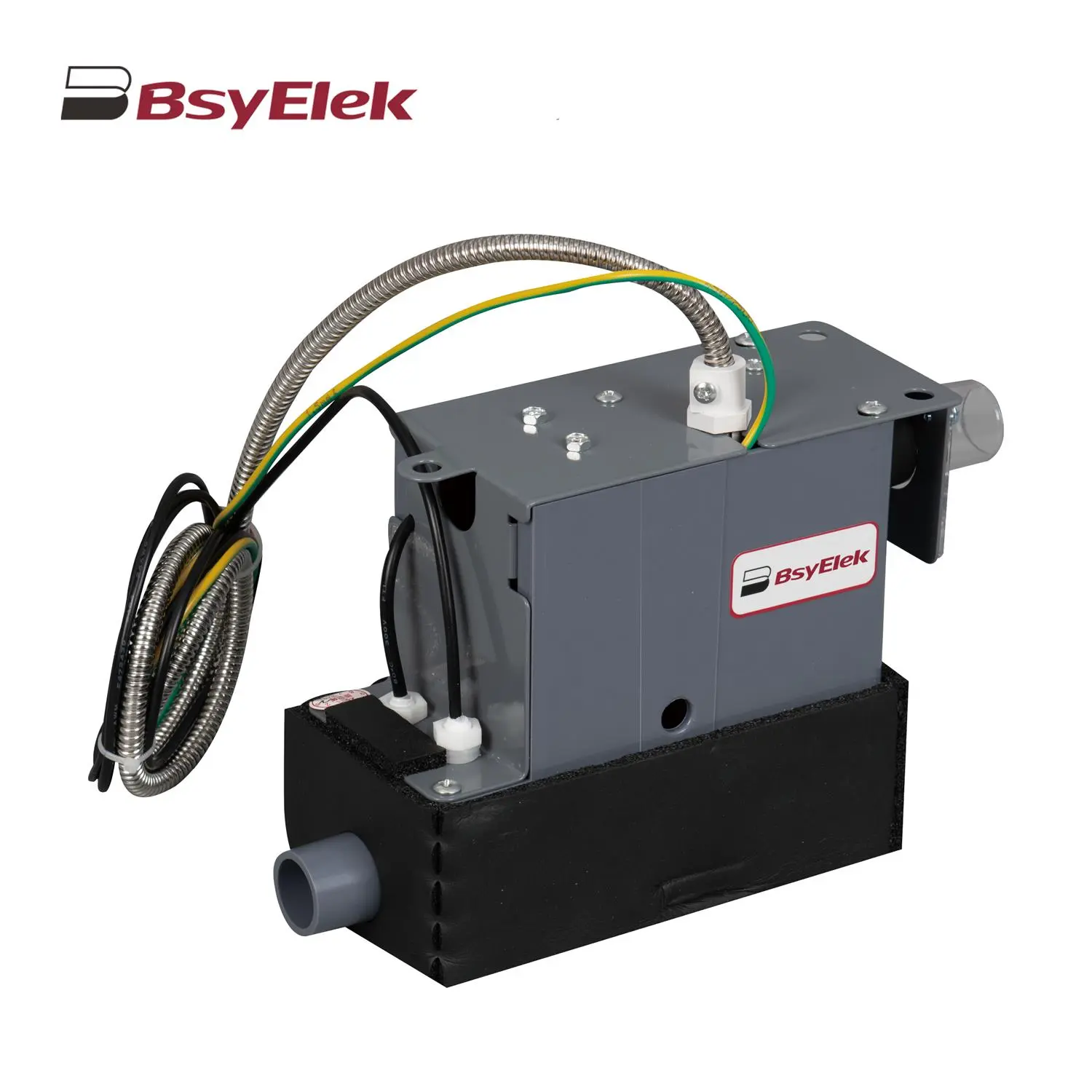

Condensate Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-24B/40B 10M Split Type Drainage Pump

BY-24B/40B 10M Split Type Drainage Pump

BY-100L 2M Drainage Pump of Air Conditioner

BY-100L 2M Drainage Pump of Air Conditioner

BY-360L 6M Large Displacement Drainage Pump

BY-360L 6M Large Displacement Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

News

Top Blog

Company News

Industry Dynamics

What is a miniature circuit breaker (MCB)?

PG Series Waterproof Cable Glands with Washer for Harsh Environments

LWSF-125 125A Manual Changeover Switch ensures reliable power transfer

BYX2 AC contactor series: reliable power control for modern electrical systems

High-performance 1000V DC fuse holder optimizes solar photovoltaic system protection

BY07L-63 Residual Current Circuit Breaker Ensures Global Electrical Safety

BYQ5 ATS Isolation Dual Power Automatic Transfer Switch

BY19G 63A Manual Changeover Switch: Features and Benefits

Support

Blog

Contact Us

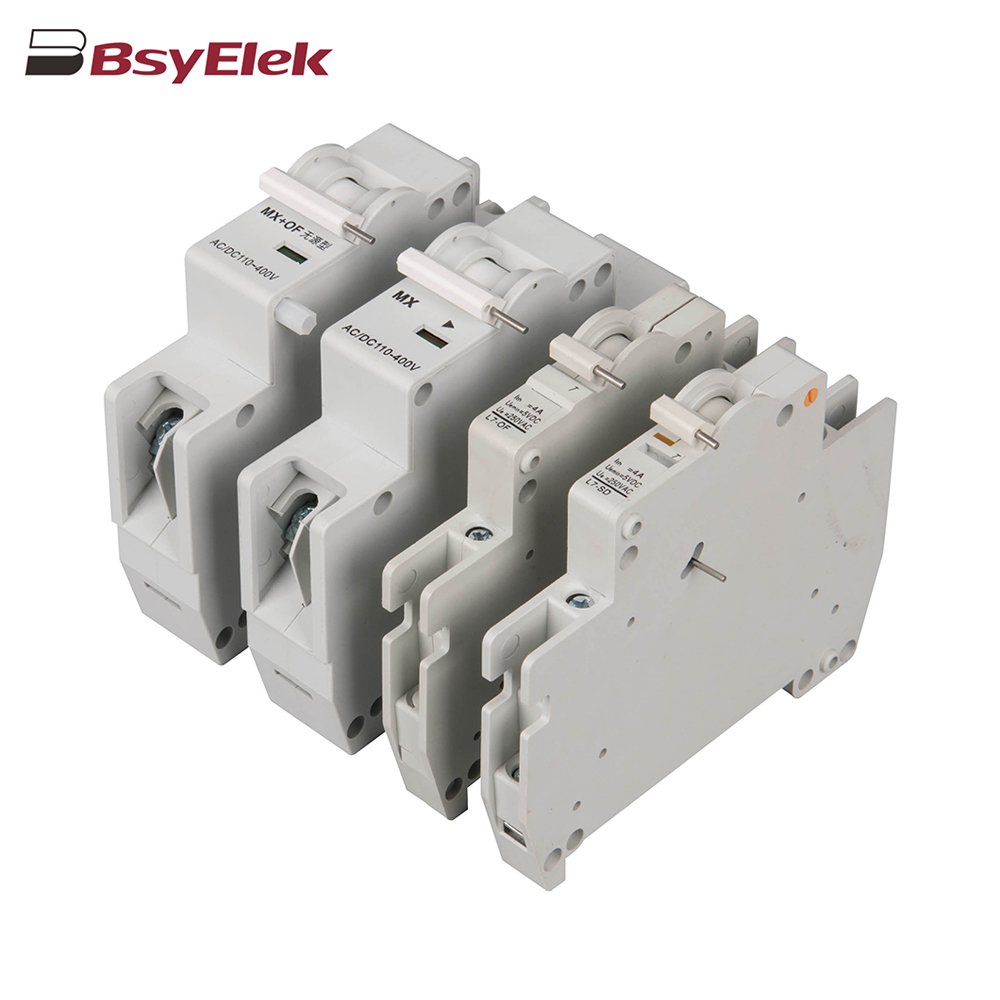

OF SD MX OF MCB Miniature Circuit Breaker Accessories

OF SD MX OF MCB Miniature Circuit Breaker Accessories BYG1-125 Main Switch MCB Isolator Switch

BYG1-125 Main Switch MCB Isolator Switch BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector

BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector

BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector BYX2 6-95A AC Contactor

BYX2 6-95A AC Contactor BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device

BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device

BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device

BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device BY19G 63A Manual Changeover Switch

BY19G 63A Manual Changeover Switch LWSF-125 125A Manual Changeover Switch

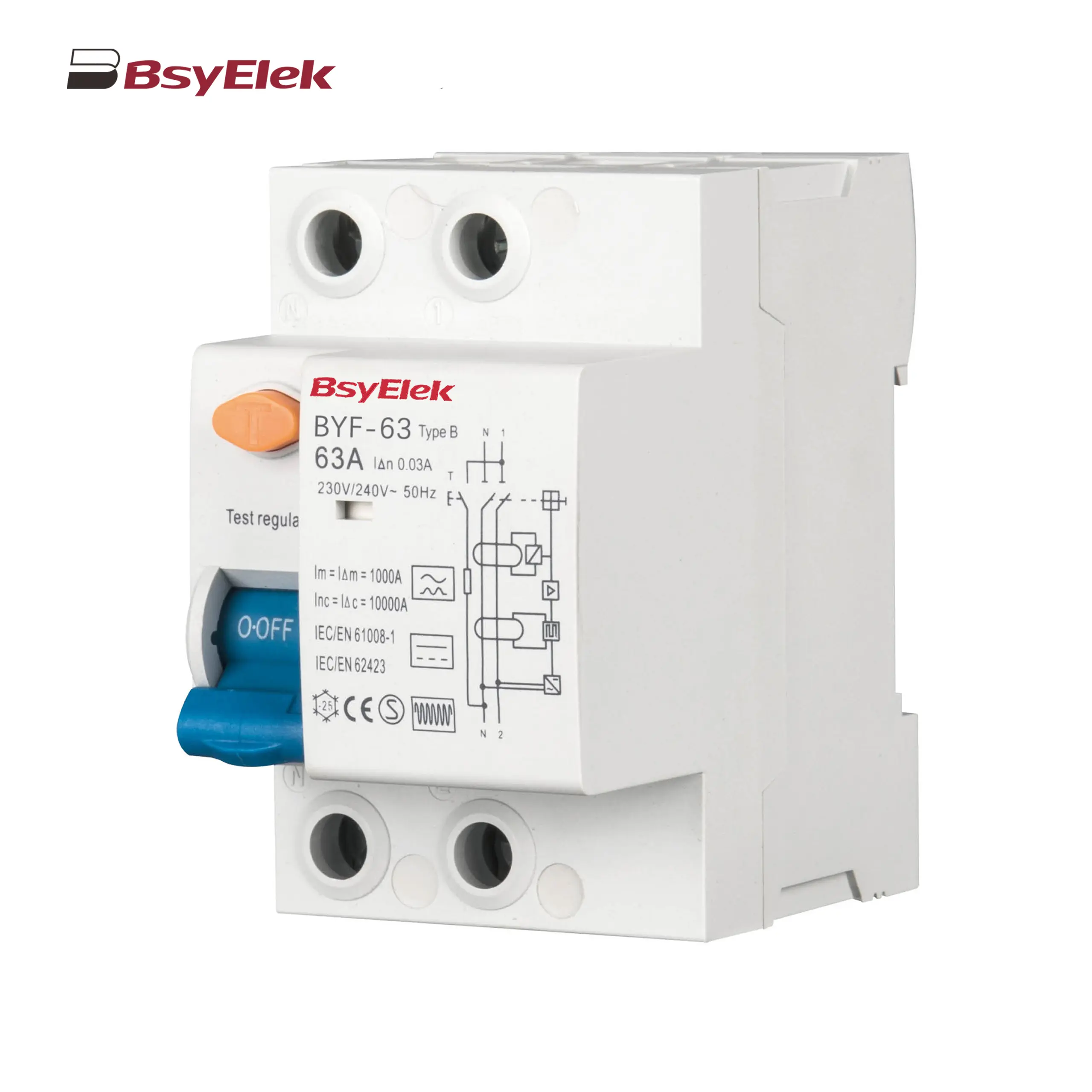

LWSF-125 125A Manual Changeover Switch BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device

BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device

BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device

BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link

BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link

BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link BYPV-ELR2 PV Isolator Switch with Enclosed Version

BYPV-ELR2 PV Isolator Switch with Enclosed Version BYPV-ELR1 PV Isolator Switch with Enclosed Version

BYPV-ELR1 PV Isolator Switch with Enclosed Version BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle

BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle BYPV-NL1 PV Isolator Switch with Lever Handle

BYPV-NL1 PV Isolator Switch with Lever Handle BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle

BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle PV-BY-01 30A/50A 1000V Photovoltaic Connector

PV-BY-01 30A/50A 1000V Photovoltaic Connector PV-BY-02 30A/50A 1500V Photovoltaic Connector

PV-BY-02 30A/50A 1500V Photovoltaic Connector PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector

PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector PV-BY-F01 30A 1500V Diode/Fuse Type Connector

PV-BY-F01 30A 1500V Diode/Fuse Type Connector PV-BY-T 50A 1500V T Type Branch Connector

PV-BY-T 50A 1500V T Type Branch Connector PV-BY-Y 30A 1500V Y Type Branch Connector

PV-BY-Y 30A 1500V Y Type Branch Connector PG Waterproof Cable Gland with Washer

PG Waterproof Cable Gland with Washer Photovoltaic Cable

Photovoltaic Cable HD11N Photovoltaic Knife Switch

HD11N Photovoltaic Knife Switch BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker

BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker

BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker BYM1E MCCB Electronic Type Molded Case Circuit Breaker

BYM1E MCCB Electronic Type Molded Case Circuit Breaker BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker

BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker BYW1 ACB Intelligent Universal Air Circuit Breaker

BYW1 ACB Intelligent Universal Air Circuit Breaker BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch

BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch Stainless Steel Hinge Type Electrical Box

Stainless Steel Hinge Type Electrical Box HA Waterproof Distribution Box

HA Waterproof Distribution Box HT Waterproof Distribution Box

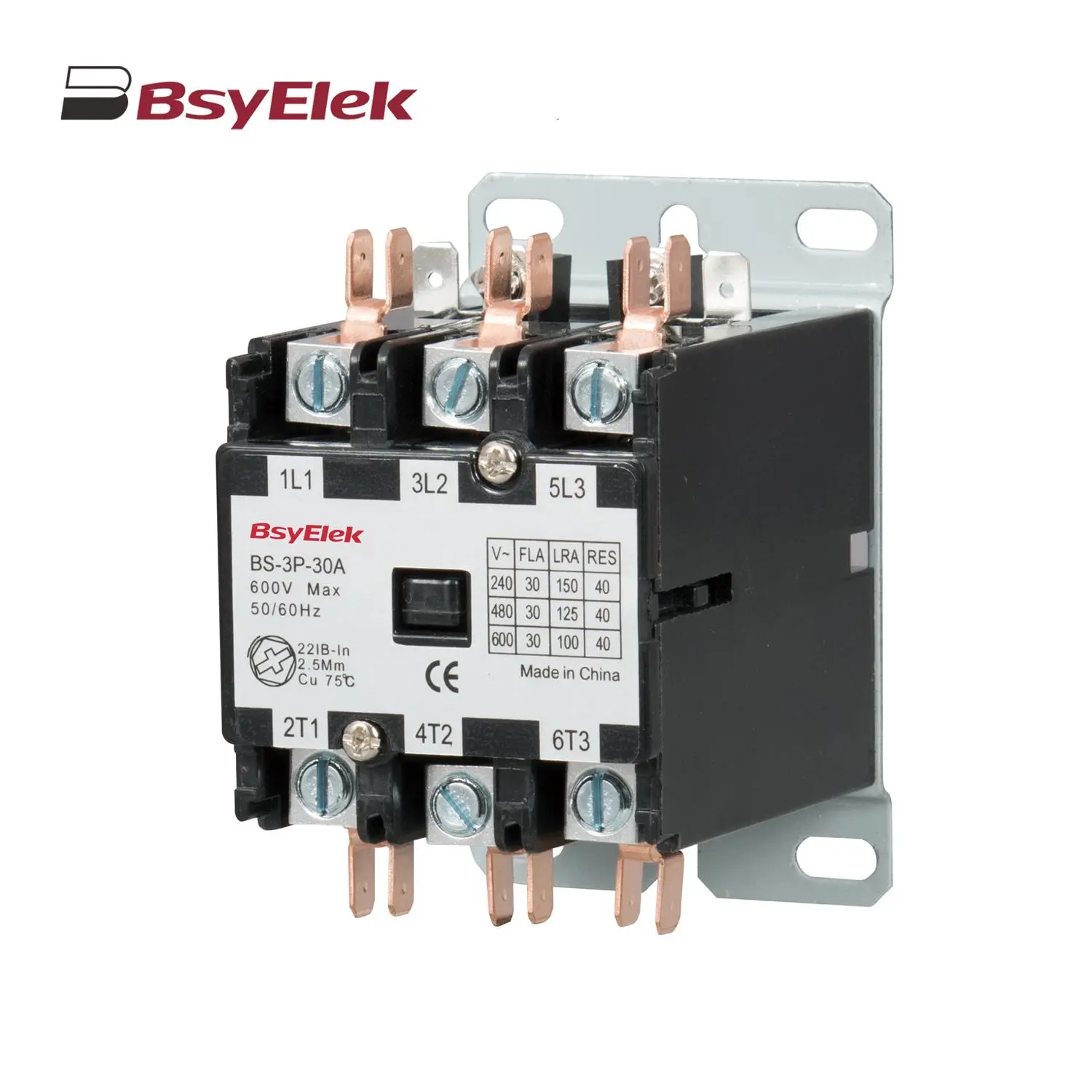

HT Waterproof Distribution Box BS Definite Purpose Magnetic AC Contactor

BS Definite Purpose Magnetic AC Contactor

When selecting a disconnect switch for your electrical system, it is crucial to consider several key factors to ensure both safety and efficiency. According to a report by the NEMA, approximately 30% of electrical incidents can be traced back to malfunctioning or improperly used disconnect switches. Therefore, understanding the specific requirements of your system is essential in preventing hazards.

When selecting a disconnect switch for your electrical system, it is crucial to consider several key factors to ensure both safety and efficiency. According to a report by the NEMA, approximately 30% of electrical incidents can be traced back to malfunctioning or improperly used disconnect switches. Therefore, understanding the specific requirements of your system is essential in preventing hazards.