Understanding the Importance of AC Contactors in Modern Electrical Systems

In contemporary electrical systems, the AC contactor plays a crucial role in managing power distribution and ensuring operational efficiency. These devices serve as electromagnetic switches that control the flow of alternating current to various equipment and machinery, allowing for automated operations that enhance productivity. Understanding how AC contactors work is vital for anyone involved in electrical engineering or maintenance, as they are integral to both residential and industrial applications.

This guide will delve into the essential functions, installation processes, and maintenance tips for AC contactors, equipping readers with the knowledge to effectively utilize these devices. Whether you are a seasoned professional or a novice in the field, this comprehensive overview will clarify the importance of AC contactors in supporting modern electrical systems and optimizing energy consumption.

The Critical Role of AC Contactors in Ensuring Electrical System Efficiency

AC contactors play a pivotal role in the efficiency of modern electrical systems. These electromechanical devices act as switches, enabling the control of high-voltage loads while ensuring safety and reliability. By facilitating the management of electrical circuits, AC contactors help prevent overloads and minimize the risk of equipment damage, thereby enhancing system performance. Their ability to handle large currents in a compact format makes them indispensable in applications ranging from industrial machinery to commercial HVAC systems.

Tips: Regular maintenance of AC contactors is essential to keep them functioning optimally. Check for signs of wear and overheating, and ensure that connections are clean and tight. Additionally, consider using contactor models with built-in overload protection to safeguard against unexpected surges.

Another significant aspect of AC contactors is their contribution to energy efficiency. By enabling precise control over electrical devices, they allow for effective load management and reduced energy consumption. This not only lowers operational costs but also supports sustainability initiatives by minimizing electricity waste. Proper selection and configuration of contactors can further enhance the overall efficiency of electrical systems.

Tips: When selecting AC contactors, ensure they are rated for the specific load requirements of your system. Pay attention to operating conditions and choose contactors designed to handle the environmental factors they will face.

Industry Statistics on AC Contactor Performance and Reliability Metrics

AC contactors play a crucial role in the functionality of modern electrical systems, particularly in industrial and commercial applications. Industry statistics have shown that reliable performance of AC contactors is essential for minimizing downtime and ensuring operational efficiency. For instance, a study revealed that systems utilizing high-quality contactors experienced a failure rate of just 2% over a five-year period, compared to 10% for those using lower-grade alternatives. This illustrates the direct correlation between the quality of contactors and the overall reliability of electrical systems.

When selecting AC contactors, it's essential to consider specific performance metrics such as coil voltage tolerance, load capacity, and operational lifespan. Tips for enhancing AC contactor reliability include regularly inspecting for signs of wear, ensuring proper matching of the contactor to the load requirements, and investing in contactors with proven track records in similar applications. Additionally, employing protective devices can safeguard contactors against voltage spikes and reduce the risk of premature failure. By focusing on these metrics and maintenance practices, industries can significantly improve the efficiency and reliability of their electrical systems.

Understanding the Performance and Reliability of AC Contactors

Understanding the Safety Standards and Compliance for AC Contactor Use

When discussing AC contactors, understanding the safety standards and compliance guidelines is essential for any electrician or technician working with modern electrical systems. These devices play a crucial role in controlling large electrical loads, and adhering to established safety standards ensures both operational efficiency and the protection of personnel and property. Compliance with standards such as UL 508 and IEC 60947 not only enhances reliability but also minimizes the risk of electrical fires and equipment damage.

Tips for ensuring compliance include regularly reviewing the latest safety standards and guidelines, conducting routine inspections of contactors for wear and tear, and ensuring that installation procedures are strictly followed. Additionally, training staff on the importance of these safety measures will foster a culture of safety and awareness.

Another important aspect of compliance is the selection of appropriate contactors for specific applications. Ensuring that the contactors are rated for the intended load and environmental conditions is vital. Always consult manufacturer specifications and guidelines when choosing or replacing AC contactors to maintain compliance and maximize safety.

Impacts of AC Contactor Quality on Energy Consumption and Costs

AC contactors play a crucial role in modern electrical systems, directly impacting energy consumption and operational costs. According to a 2022 report by the International Electrotechnical Commission (IEC), high-quality AC contactors can reduce energy losses by up to 15%. This improvement arises from enhanced efficiency leading to minimal heat generation during operation, which translates into lower electricity expenses. Industries that rely heavily on motors and HVAC systems particularly benefit from these savings, often recouping the initial investment in quality contactors within a year due to reduced energy bills.

Moreover, the choice of AC contactors can significantly affect maintenance costs and system longevity. A study by the National Electrical Manufacturers Association (NEMA) indicated that systems employing lower-quality contactors experienced failure rates up to 30% higher compared to those with better-quality components. Frequent failures not only lead to increased downtime but also escalate repair and replacement costs. Investing in high-grade AC contactors ensures consistent performance, reduces the total cost of ownership, and maximizes the efficiency of electrical operations, illustrating the profound impact of quality on overall energy consumption and financial expenditures in industrial applications.

An Overview of Technological Advances in AC Contactor Design and Functionality

The evolution of AC contactors is a testament to the rapid advancements in electrical technology. Modern designs have shifted towards increased energy efficiency, reduced physical size, and enhanced functionality. With the integration of smart technologies, contemporary AC contactors are equipped with sensors and communication capabilities that allow them to integrate seamlessly into automated systems. This not only improves operational efficiency but also ensures greater reliability and control over electrical loads.

Moreover, advancements in materials and manufacturing processes have led to the development of contactors that can withstand extreme conditions while maintaining optimal performance. For instance, improved insulation materials and contact designs have significantly enhanced their durability and energy consumption. Additionally, features such as built-in diagnostic tools provide real-time feedback on performance, making maintenance more efficient. Overall, these technological innovations are pivotal in meeting the demands of modern electrical systems, allowing for smarter, safer, and more sustainable energy management.

Home

About Us

Products

Terminal Power Distribution Electric

AC Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

MCB Accessories

Main Switch

RCBO RCCB

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

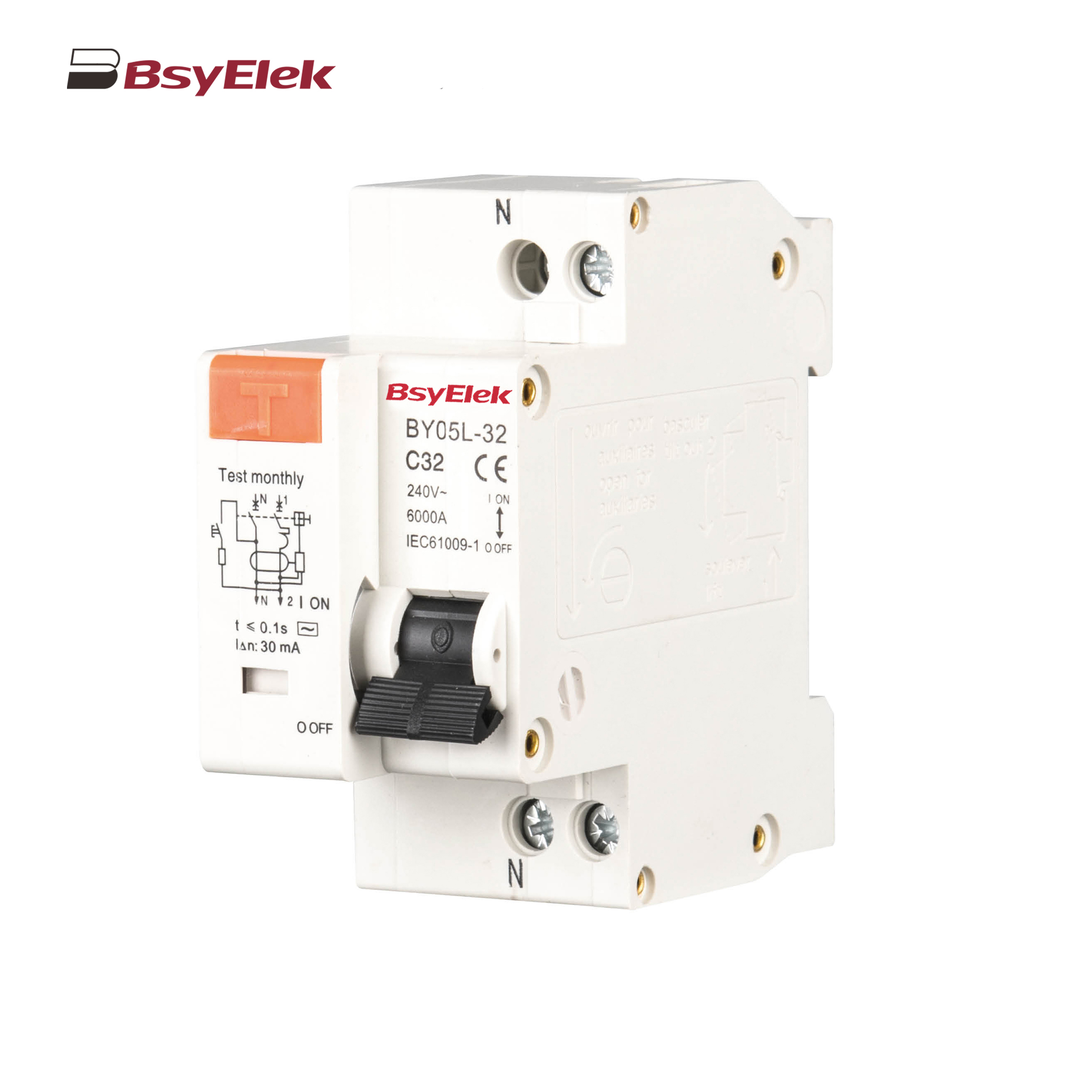

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

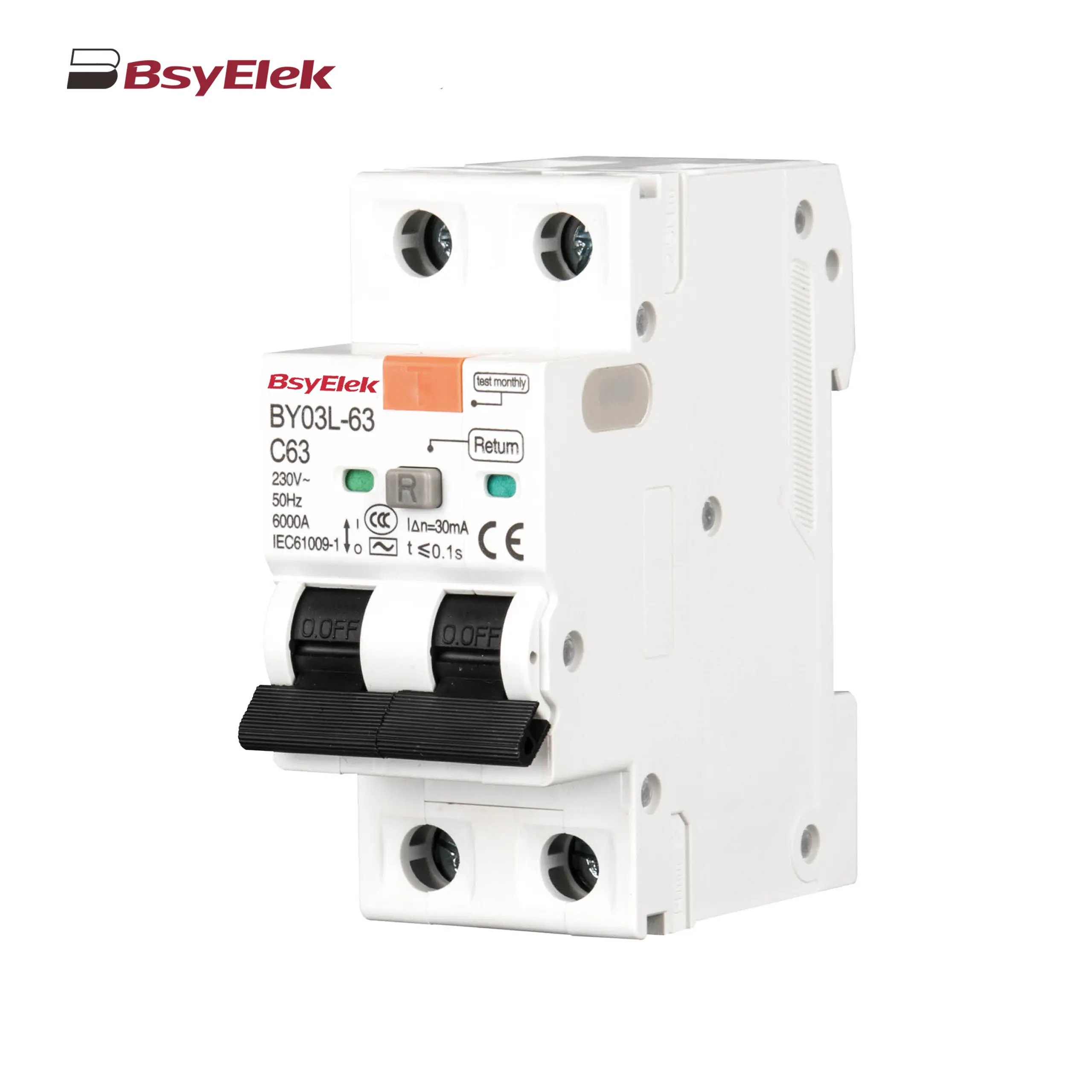

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

Resettable Overvoltage and Undervoltage Protector

AC Contactor

AC Surge Protective Device

Changeover Switch

Photovoltaic System Protection

DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

RCD

DC Surge Protective Device

DC Fuse

PV Isolator Switch

PV Connector

Cable Gland

PV Cable

PV Knife Switch

DC Molded Case Circuit Breaker

Industrial Power Distribution Electric

Distribution Box

Air Conditioning System

Definite Purpose Magnetic Contactor

Condensate Pump

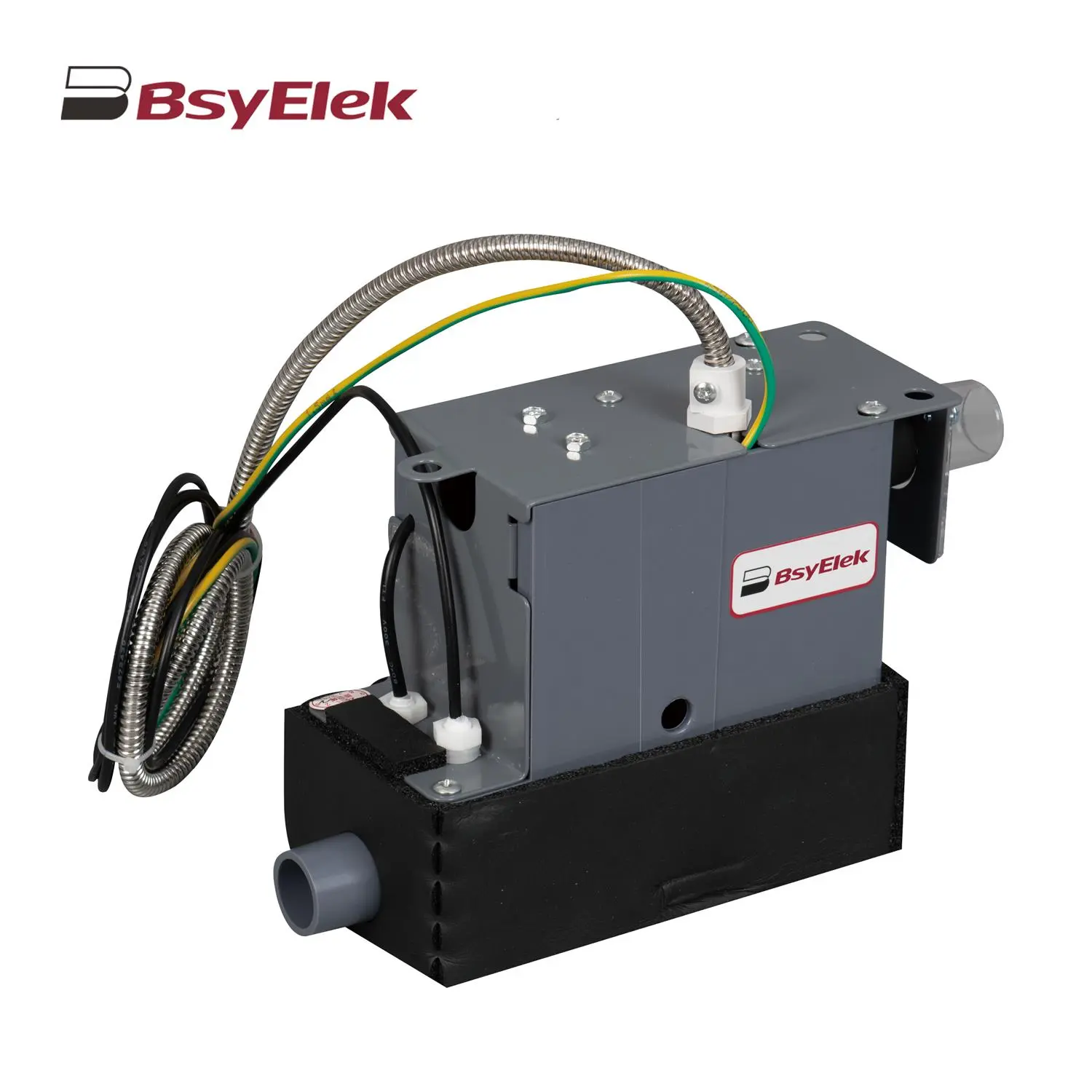

BY-5018 1.8M Engineering Drainage Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-24B/40B 10M Split Type Drainage Pump

BY-24B/40B 10M Split Type Drainage Pump

BY-100L 2M Drainage Pump of Air Conditioner

BY-100L 2M Drainage Pump of Air Conditioner

BY-360L 6M Large Displacement Drainage Pump

BY-360L 6M Large Displacement Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

News

Top Blog

Company News

Industry Dynamics

What is a miniature circuit breaker (MCB)?

PG Series Waterproof Cable Glands with Washer for Harsh Environments

LWSF-125 125A Manual Changeover Switch ensures reliable power transfer

BYX2 AC contactor series: reliable power control for modern electrical systems

High-performance 1000V DC fuse holder optimizes solar photovoltaic system protection

BY07L-63 Residual Current Circuit Breaker Ensures Global Electrical Safety

BYQ5 ATS Isolation Dual Power Automatic Transfer Switch

BY19G 63A Manual Changeover Switch: Features and Benefits

Support

Blog

Contact Us

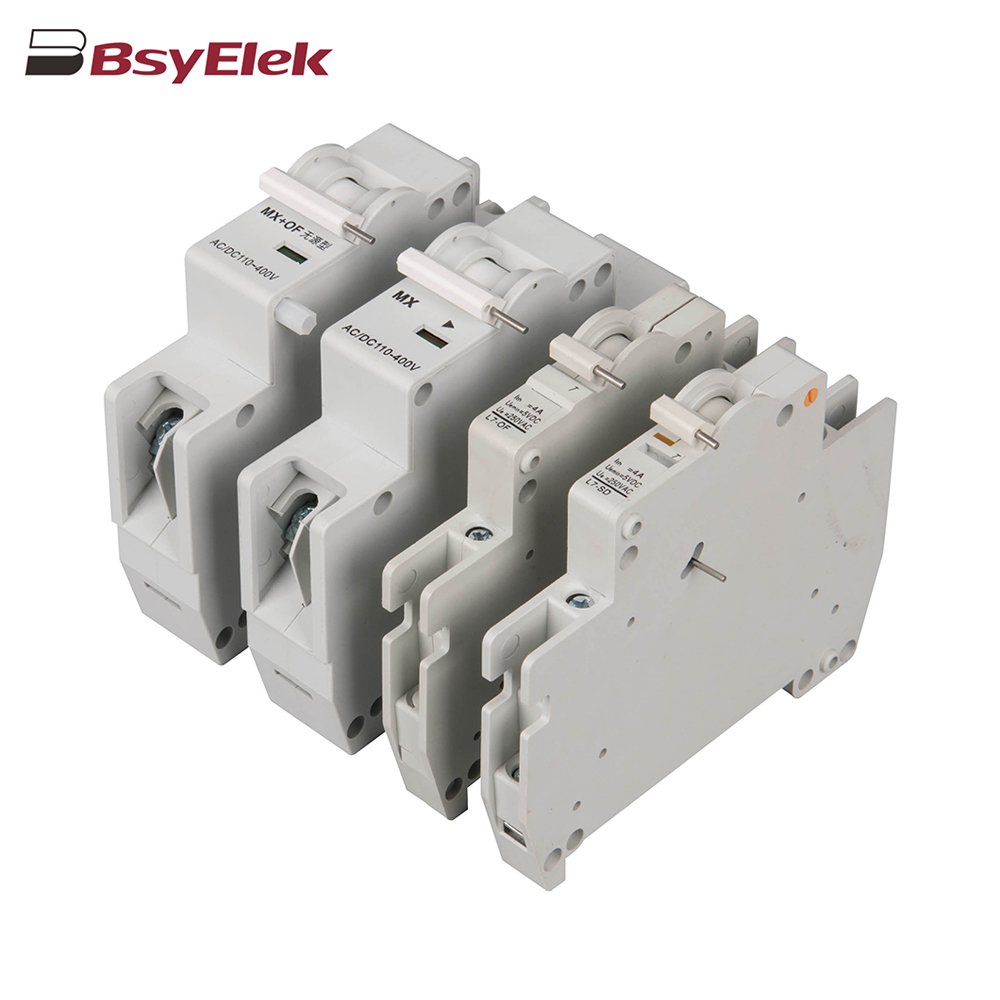

OF SD MX OF MCB Miniature Circuit Breaker Accessories

OF SD MX OF MCB Miniature Circuit Breaker Accessories BYG1-125 Main Switch MCB Isolator Switch

BYG1-125 Main Switch MCB Isolator Switch BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector

BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector

BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector BYX2 6-95A AC Contactor

BYX2 6-95A AC Contactor BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device

BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device

BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device

BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device BY19G 63A Manual Changeover Switch

BY19G 63A Manual Changeover Switch LWSF-125 125A Manual Changeover Switch

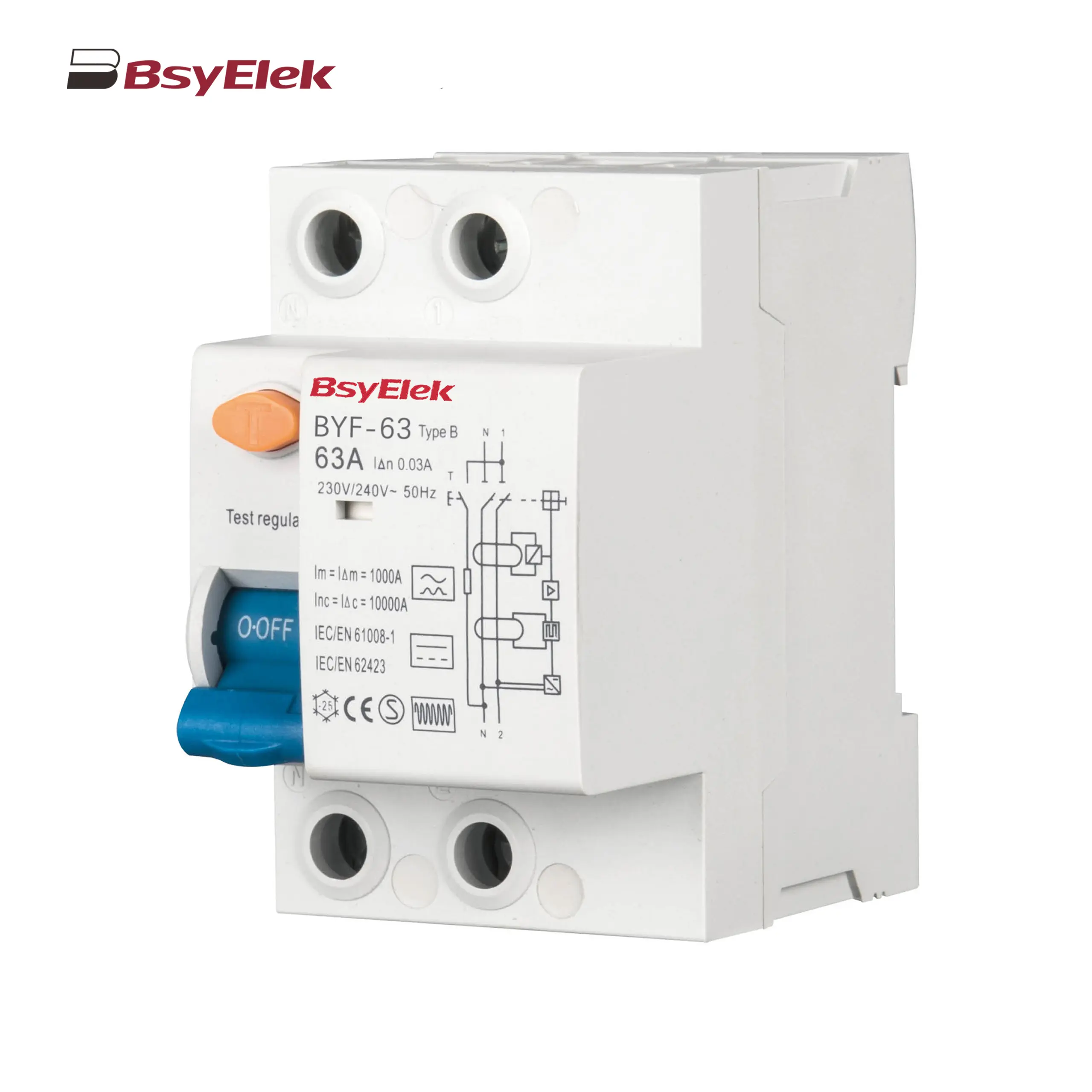

LWSF-125 125A Manual Changeover Switch BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device

BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device

BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device

BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link

BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link

BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link BYPV-ELR2 PV Isolator Switch with Enclosed Version

BYPV-ELR2 PV Isolator Switch with Enclosed Version BYPV-ELR1 PV Isolator Switch with Enclosed Version

BYPV-ELR1 PV Isolator Switch with Enclosed Version BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle

BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle BYPV-NL1 PV Isolator Switch with Lever Handle

BYPV-NL1 PV Isolator Switch with Lever Handle BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle

BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle PV-BY-01 30A/50A 1000V Photovoltaic Connector

PV-BY-01 30A/50A 1000V Photovoltaic Connector PV-BY-02 30A/50A 1500V Photovoltaic Connector

PV-BY-02 30A/50A 1500V Photovoltaic Connector PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector

PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector PV-BY-F01 30A 1500V Diode/Fuse Type Connector

PV-BY-F01 30A 1500V Diode/Fuse Type Connector PV-BY-T 50A 1500V T Type Branch Connector

PV-BY-T 50A 1500V T Type Branch Connector PV-BY-Y 30A 1500V Y Type Branch Connector

PV-BY-Y 30A 1500V Y Type Branch Connector PG Waterproof Cable Gland with Washer

PG Waterproof Cable Gland with Washer Photovoltaic Cable

Photovoltaic Cable HD11N Photovoltaic Knife Switch

HD11N Photovoltaic Knife Switch BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker

BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker

BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker BYM1E MCCB Electronic Type Molded Case Circuit Breaker

BYM1E MCCB Electronic Type Molded Case Circuit Breaker BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker

BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker BYW1 ACB Intelligent Universal Air Circuit Breaker

BYW1 ACB Intelligent Universal Air Circuit Breaker BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch

BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch Stainless Steel Hinge Type Electrical Box

Stainless Steel Hinge Type Electrical Box HA Waterproof Distribution Box

HA Waterproof Distribution Box HT Waterproof Distribution Box

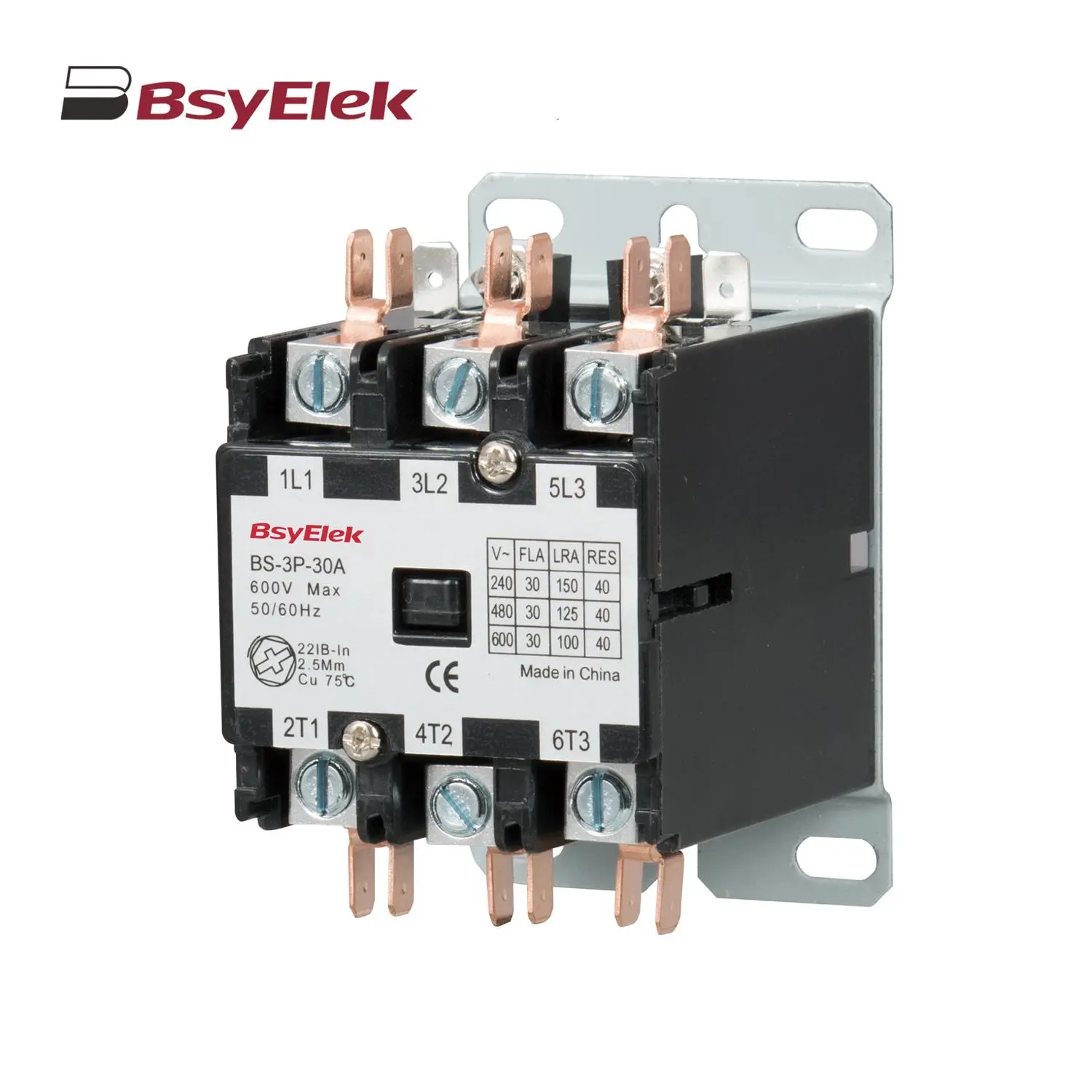

HT Waterproof Distribution Box BS Definite Purpose Magnetic AC Contactor

BS Definite Purpose Magnetic AC Contactor