Future Proof Your Power Systems with the 2025 Checklist for Best Molded Case Circuit Breakers

In an era where electrical infrastructure faces increasing demands and evolving technologies, ensuring the reliability and efficiency of power systems is paramount. Molded Case Circuit Breakers (MCCBs) play a crucial role in safeguarding electrical circuits from overloads and short circuits, which can lead to catastrophic failures and costly downtimes.

According to the latest Global Market Insights report, the MCCB market is anticipated to exceed $18 billion by 2025, evidencing the growing reliance on these devices in both industrial and commercial applications. However, as we look toward the future, it is essential to address common problems associated with MCCBs, including inadequate sizing, failure to meet environmental standards, and the impact of digitalization on traditional circuit protection methods.

By adhering to a comprehensive checklist for best practices, stakeholders can future-proof their power systems and enhance their operational resilience.

Best Practices for Selecting Molded Case Circuit Breakers in Modern Power Systems

In modern power systems, selecting the right molded case circuit breakers (MCCBs) is critical for ensuring reliability and efficiency. As energy demands escalate and systems become increasingly complex, the need for advanced protective solutions is undeniable. Recent industry reports indicate that the global MCCB market is expected to reach $8.5 billion by 2025, driven by the integration of smart technologies that enhance energy management and system safety.

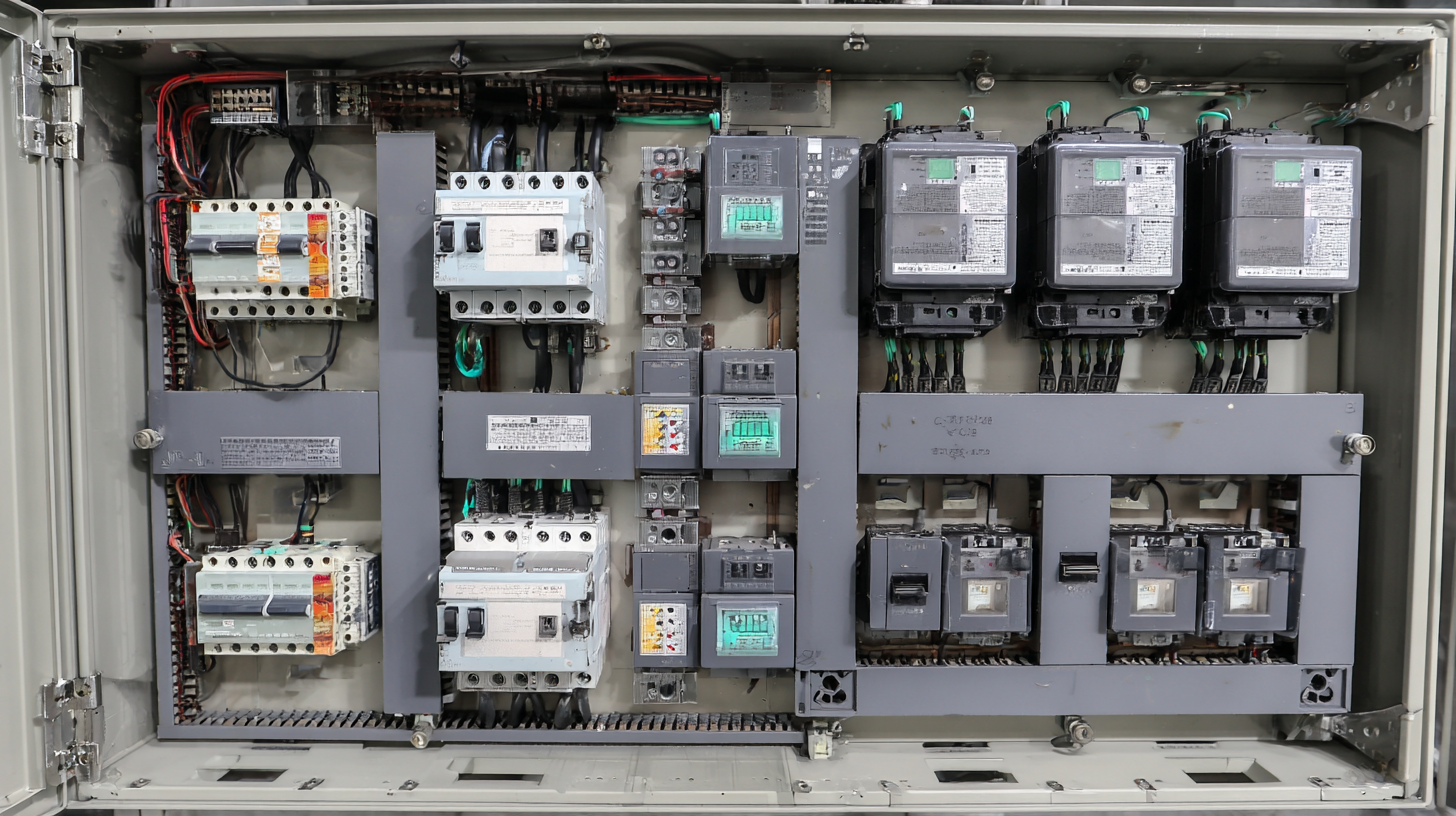

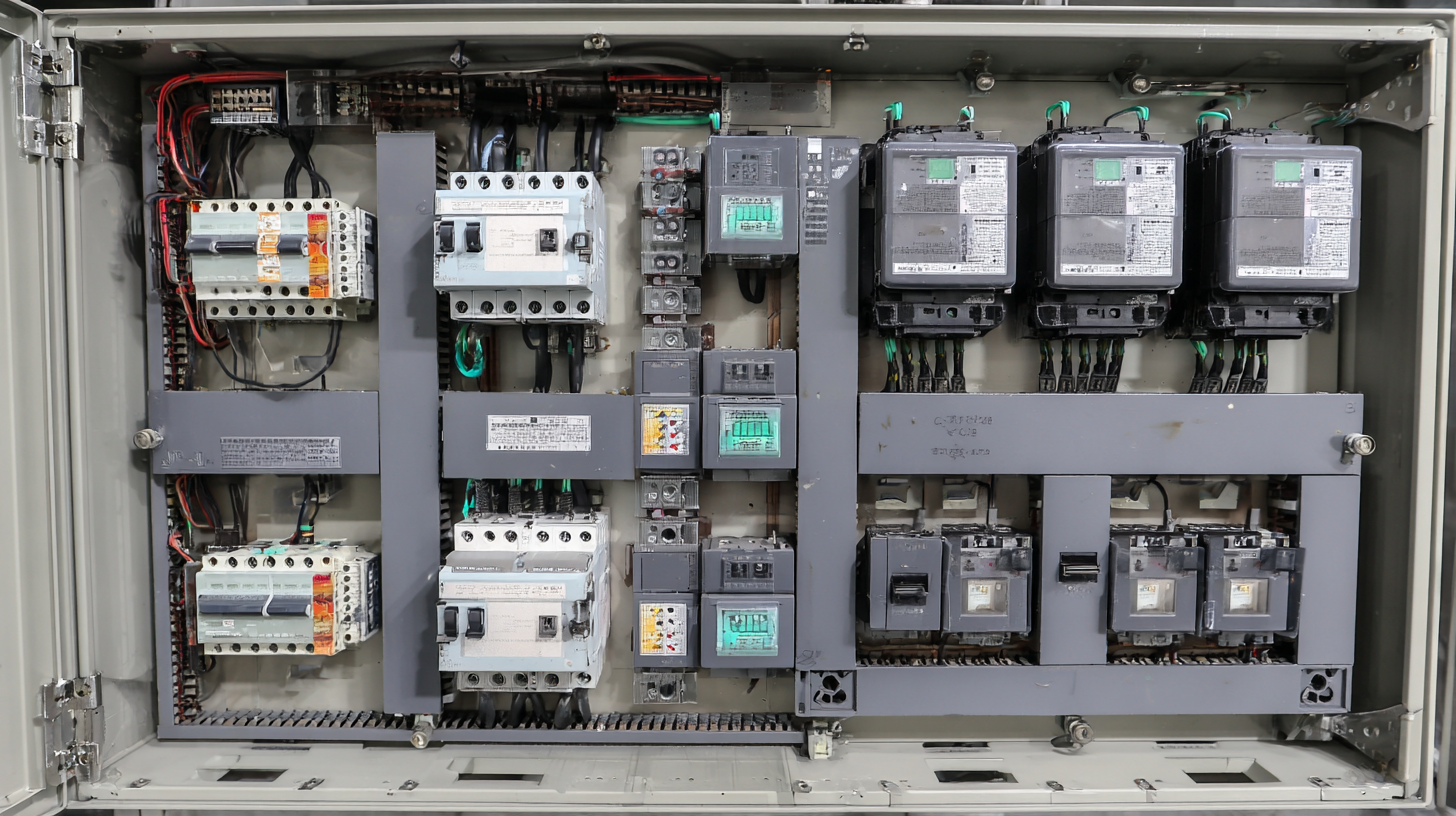

When choosing MCCBs, it's essential to consider aspects such as modularity, intelligence, and connectivity. Modern MCCBs offer features that extend beyond traditional circuit protection, including built-in energy metering and intelligent diagnostic tools. These innovations not only provide real-time monitoring but also aid in predictive maintenance, reducing downtime and improving overall system performance. Adopting best practices in selecting MCCBs can significantly contribute to future-proofing your power systems, ensuring they can adapt to evolving electrical demands and regulatory requirements.

Furthermore, with a comprehensive range of accessory components available for modern MCCBs, operators can customize their systems to better fit specific operational needs. By prioritizing intelligent and modular solutions, businesses can enhance efficiency and reduce costs, making informed choices that align with both current and future energy landscapes.

Key Features of Molded Case Circuit Breakers: Ensuring Reliability and Safety

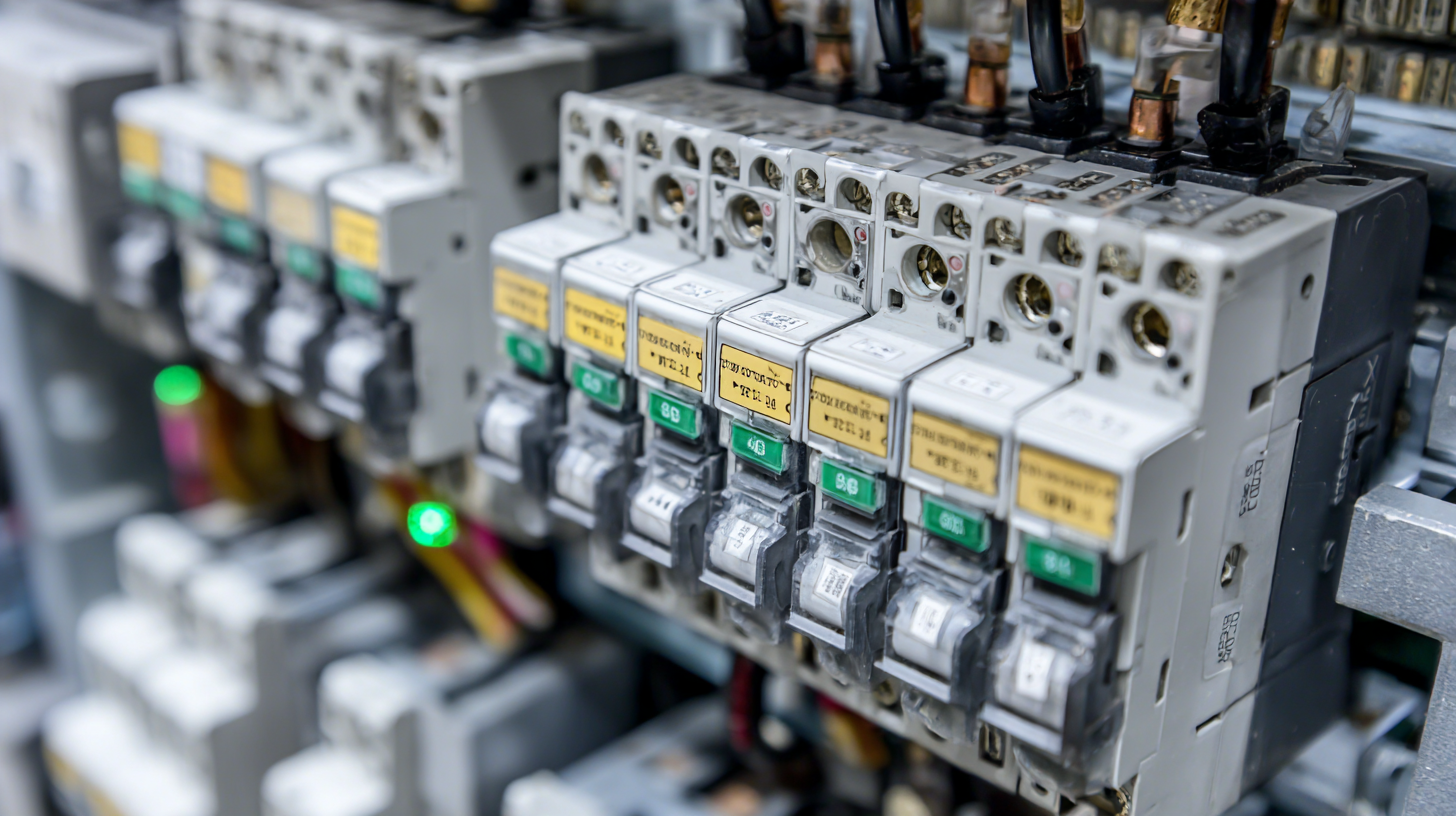

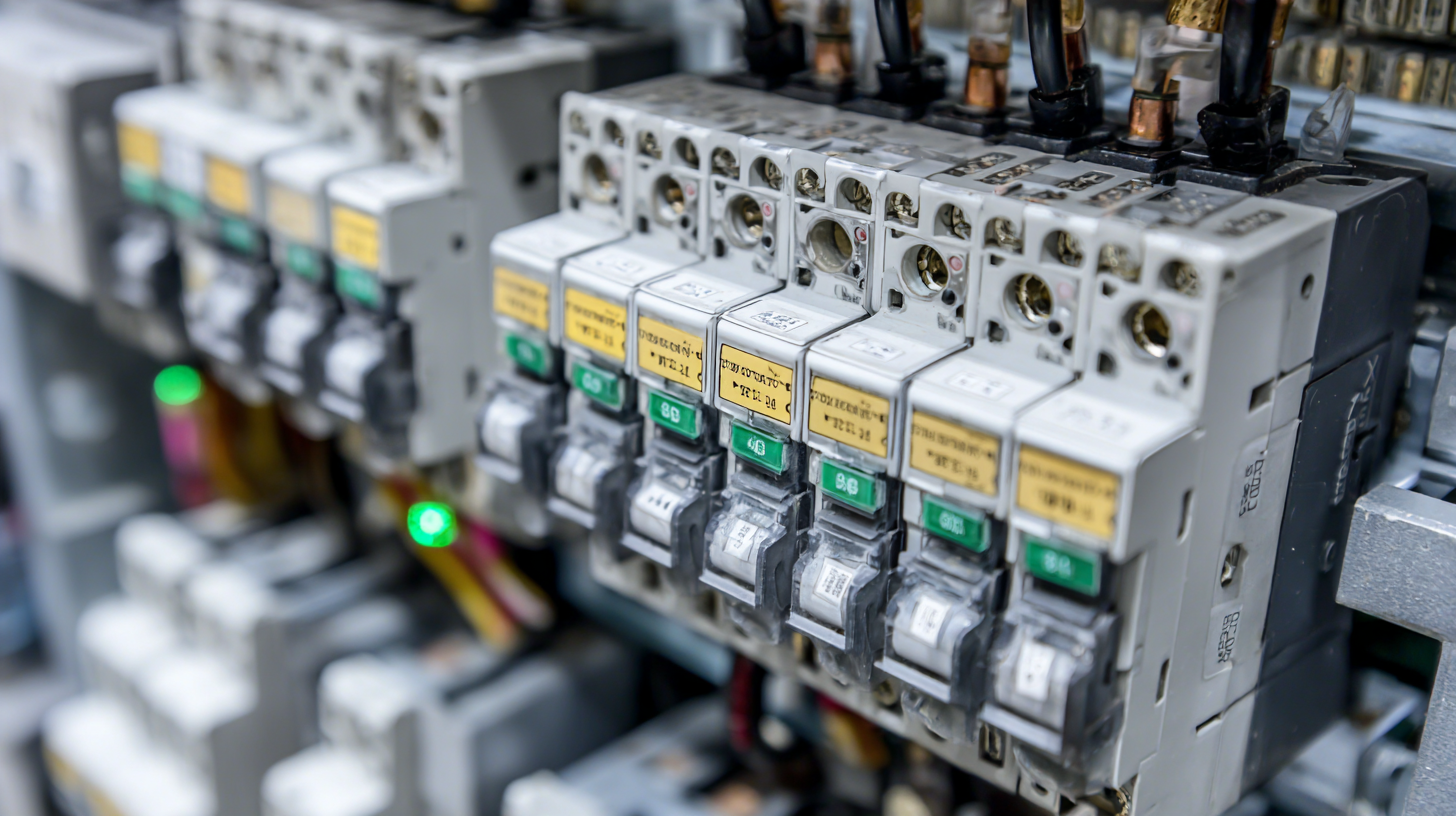

Molded Case Circuit Breakers (MCCBs) are essential components in modern power systems, providing both reliability and safety. According to a 2023 report by MarketsandMarkets, the global MCCB market is projected to reach $7.5 billion by 2025, driven by demands for energy-efficient solutions and stringent safety regulations. Key features to consider when selecting MCCBs include thermal and magnetic trip settings, which protect against overloads and short circuits, ensuring minimal downtime and enhanced operational safety.

**Tip:** Always verify the rating of MCCBs in relation to your specific application. Selecting the appropriate current rating ensures that the breakers will operate effectively without nuisance tripping, thereby safeguarding equipment and maintaining system integrity.

Another crucial aspect of MCCBs is their ability to communicate with modern control systems. Many of today’s breakers come equipped with advanced monitoring features, such as real-time data analysis and remote accessibility, enhancing oversight and proactive maintenance. A recent study from the International Electrotechnical Commission noted that integrating smart technology into circuit protection can reduce system failures by up to 30%.

**Tip:** When upgrading your power systems, consider MCCBs with smart technology integration. This will not only enhance safety but also optimize energy management, allowing for adjustments based on real-time demand.

Future Proof Your Power Systems with the 2025 Checklist for Best Molded Case Circuit Breakers - Key Features of Molded Case Circuit Breakers: Ensuring Reliability and Safety

| Key Feature |

Description |

Importance |

Compliance Standards |

| Overload Protection |

Prevents damage from excessive current |

Critical for equipment longevity |

IEC 60947-2 |

| Short Circuit Protection |

Safeguards against sudden surges |

Essential for safety and operation |

UL 489, IEC 60947-2 |

| Dual Ratings |

Allows for versatility in applications |

Useful for various operational needs |

NEMA, IEC Compliance |

| Thermal Magnetic Trip |

Combines thermal and magnetic protection |

Reliable response to overloads |

IEC 60947-2 |

| Modularity |

Easy to expand and adapt to future needs |

Future-proofing solutions |

R&D Standards |

Evaluating the Performance Metrics of Molded Case Circuit Breakers in Industrial Applications

In industrial applications, the performance metrics of Molded Case Circuit Breakers (MCCBs) play a crucial role in ensuring safety and reliability. Evaluating these metrics involves assessing key factors such as interrupting capacity, thermal-magnetic performance, and operational durability. The interrupting capacity of an MCCB determines its ability to handle short circuits, which is essential in preventing equipment damage and ensuring personnel safety.

Understanding the specific interrupting ratings required for various applications can help in selecting the right breaker for diverse environments.

Moreover, thermal-magnetic performance is critical in protecting against overload conditions and short circuits. An MCCB’s response time to these situations can significantly impact overall system performance and can vary between different models. It’s important for industrial operators to consider how quickly a breaker can react to surges in current, which could otherwise lead to equipment failure. Lastly, evaluating an MCCB’s operational durability, including its mechanical and electrical lifespan, ensures long-term reliability in demanding industrial settings. By focusing on these performance metrics, businesses can future-proof their power systems and enhance operational efficiency.

Understanding the Regulatory Standards Impacting Molded Case Circuit Breakers by 2025

As we approach the regulatory landscape of 2025, understanding the standards for molded case circuit breakers (MCCBs) becomes crucial for power system professionals. The changing regulatory environment is shaped by advancements in technology, with an emphasis on safety, efficiency, and environmental sustainability. By 2025, MCCBs will likely be required to meet more stringent criteria that address energy consumption, reduce greenhouse gas emissions, and improve overall reliability in performance.

Key regulations will include updated performance metrics and more rigorous testing protocols to ensure that MCCBs can withstand extreme operating conditions. Compliance will not only protect facilities from costly outages but also enhance the environmental credentials of organizations. Manufacturers and end-users alike must prioritize these evolving standards to future-proof their power systems against regulatory non-compliance and potential penalties. By staying informed and adapting to these changes, businesses can secure their operations while contributing to a more sustainable future.

Future Trends in Molded Case Circuit Breaker Technology and Their Implications for Energy Efficiency

As we move towards a more energy-conscious future, the evolution of molded case circuit breakers (MCCBs) plays a crucial role in enhancing energy efficiency across various sectors. The 2025 checklist emphasizes the importance of integrating advanced technologies such as IoT and predictive analytics into MCCBs.

These innovations allow for real-time monitoring and diagnostics, enabling facilities to anticipate issues before they escalate into significant problems. By adopting these smart features, organizations can not only reduce downtime but also enhance overall power management.

Moreover, future trends indicate a shift towards the use of sustainable materials and designs in the manufacturing of MCCBs. This trend is driven by an increasing awareness of environmental impact, leading to the incorporation of recyclable materials and energy-efficient manufacturing processes.

As regulations become more stringent and consumers demand greener solutions, companies that prioritize these developments can position themselves as leaders in energy efficiency. Investing in updated MCCB technology now ensures compliance with future standards while promoting a sustainable operational footprint.

Home

About Us

Products

Terminal Power Distribution Electric

AC Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

MCB Accessories

Main Switch

RCBO RCCB

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

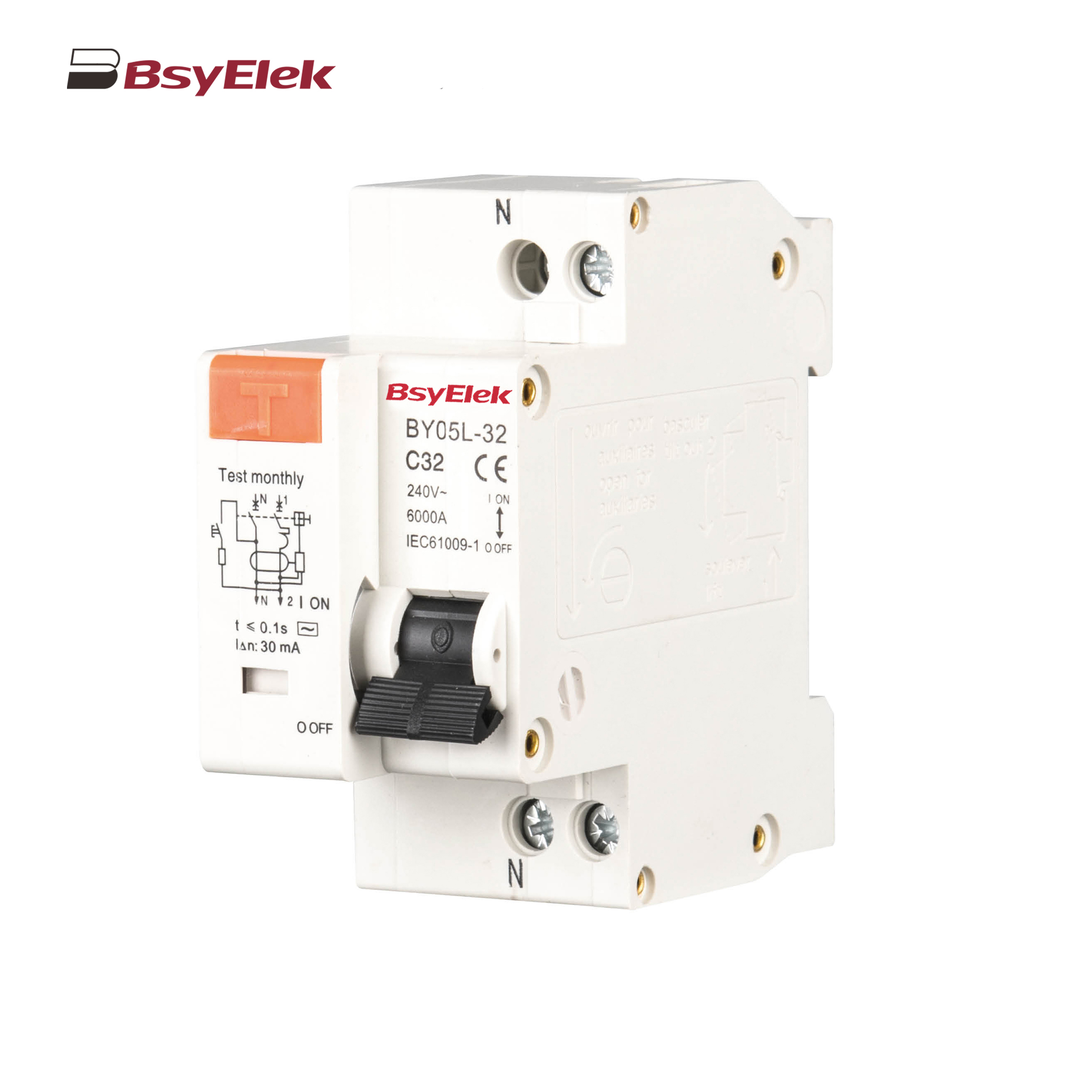

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

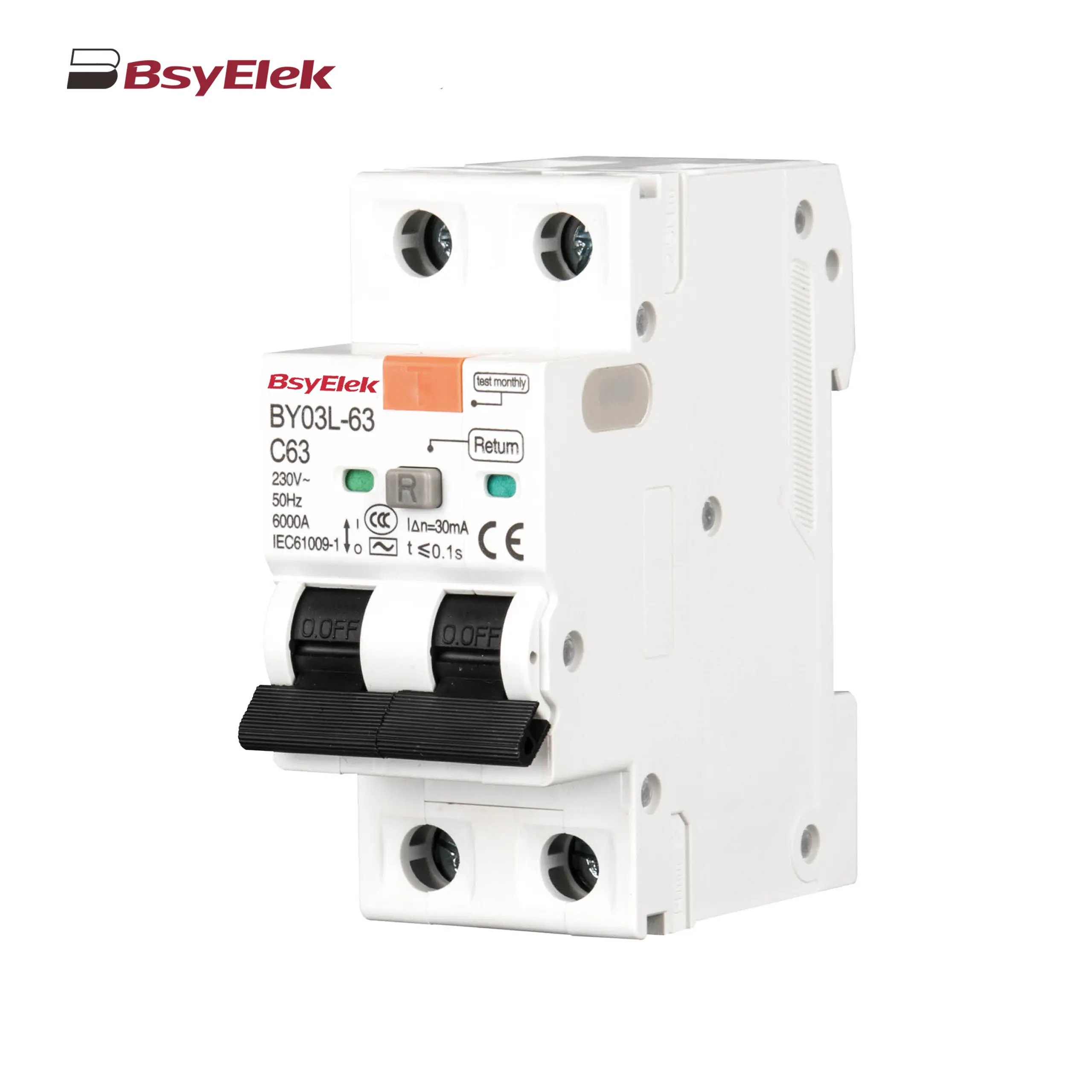

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

Resettable Overvoltage and Undervoltage Protector

AC Contactor

AC Surge Protective Device

Changeover Switch

Photovoltaic System Protection

DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

RCD

DC Surge Protective Device

DC Fuse

PV Isolator Switch

PV Connector

Cable Gland

PV Cable

PV Knife Switch

DC Molded Case Circuit Breaker

Industrial Power Distribution Electric

Distribution Box

Air Conditioning System

Definite Purpose Magnetic Contactor

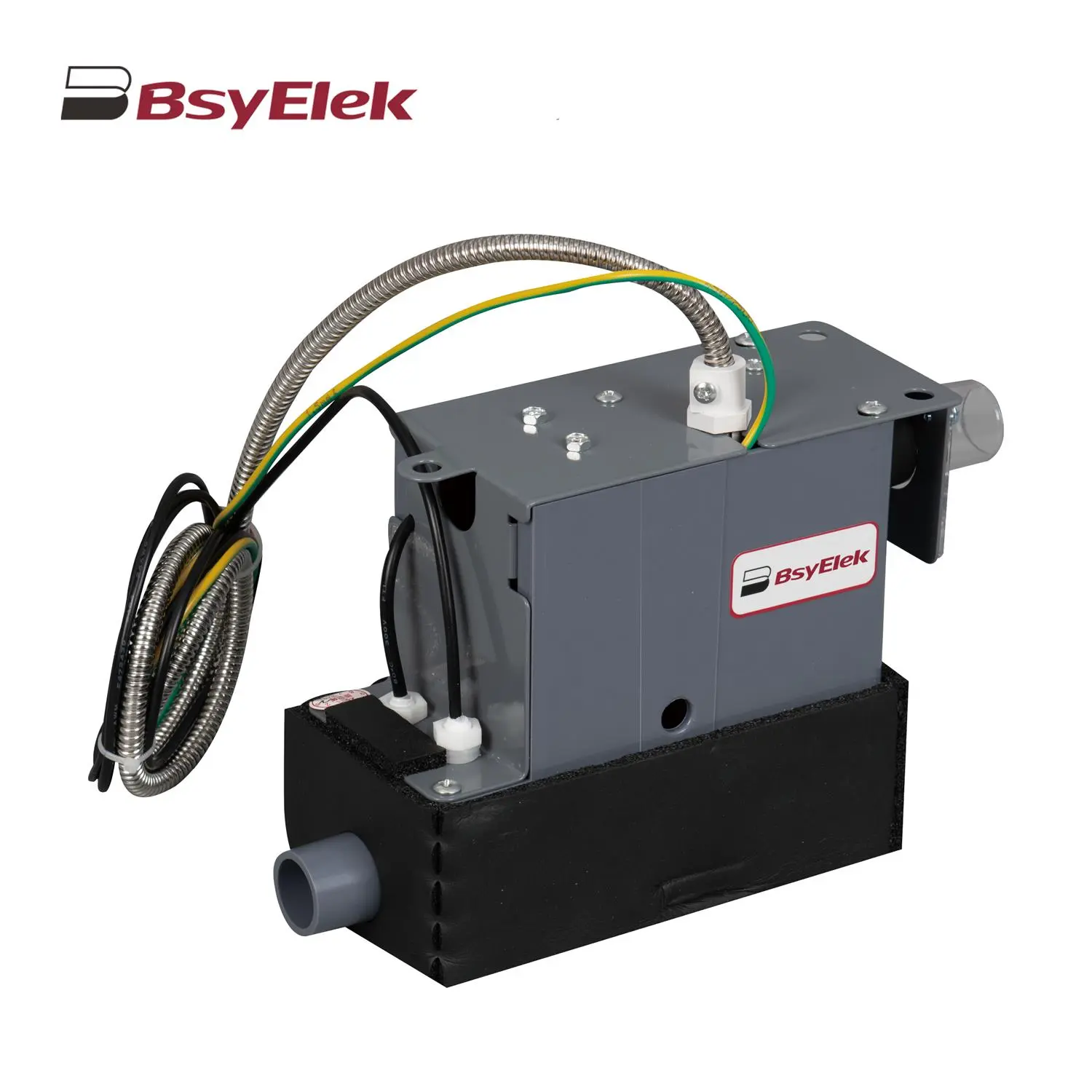

Condensate Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-24B/40B 10M Split Type Drainage Pump

BY-24B/40B 10M Split Type Drainage Pump

BY-100L 2M Drainage Pump of Air Conditioner

BY-100L 2M Drainage Pump of Air Conditioner

BY-360L 6M Large Displacement Drainage Pump

BY-360L 6M Large Displacement Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

News

Top Blog

Company News

Industry Dynamics

What is a miniature circuit breaker (MCB)?

PG Series Waterproof Cable Glands with Washer for Harsh Environments

LWSF-125 125A Manual Changeover Switch ensures reliable power transfer

BYX2 AC contactor series: reliable power control for modern electrical systems

High-performance 1000V DC fuse holder optimizes solar photovoltaic system protection

BY07L-63 Residual Current Circuit Breaker Ensures Global Electrical Safety

BYQ5 ATS Isolation Dual Power Automatic Transfer Switch

BY19G 63A Manual Changeover Switch: Features and Benefits

Support

Blog

Contact Us

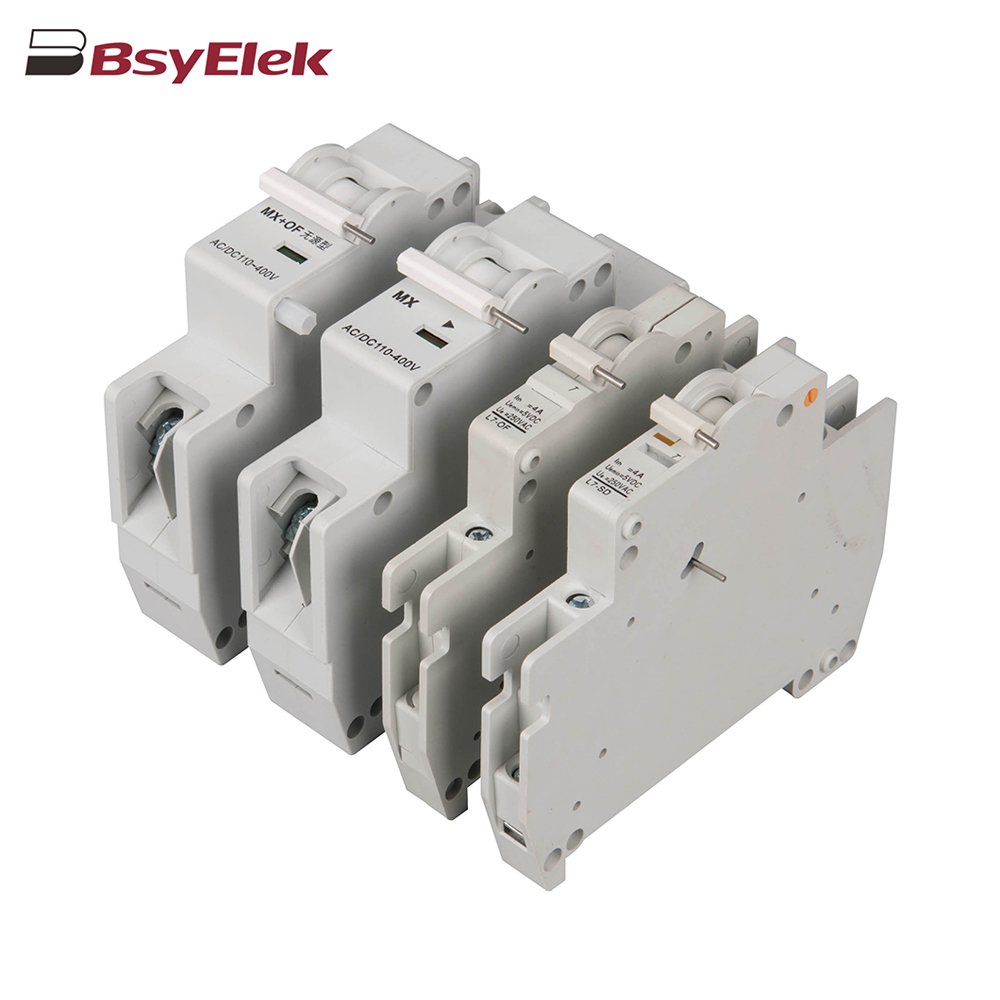

OF SD MX OF MCB Miniature Circuit Breaker Accessories

OF SD MX OF MCB Miniature Circuit Breaker Accessories BYG1-125 Main Switch MCB Isolator Switch

BYG1-125 Main Switch MCB Isolator Switch BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector

BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector

BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector BYX2 6-95A AC Contactor

BYX2 6-95A AC Contactor BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device

BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device

BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device

BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device BY19G 63A Manual Changeover Switch

BY19G 63A Manual Changeover Switch LWSF-125 125A Manual Changeover Switch

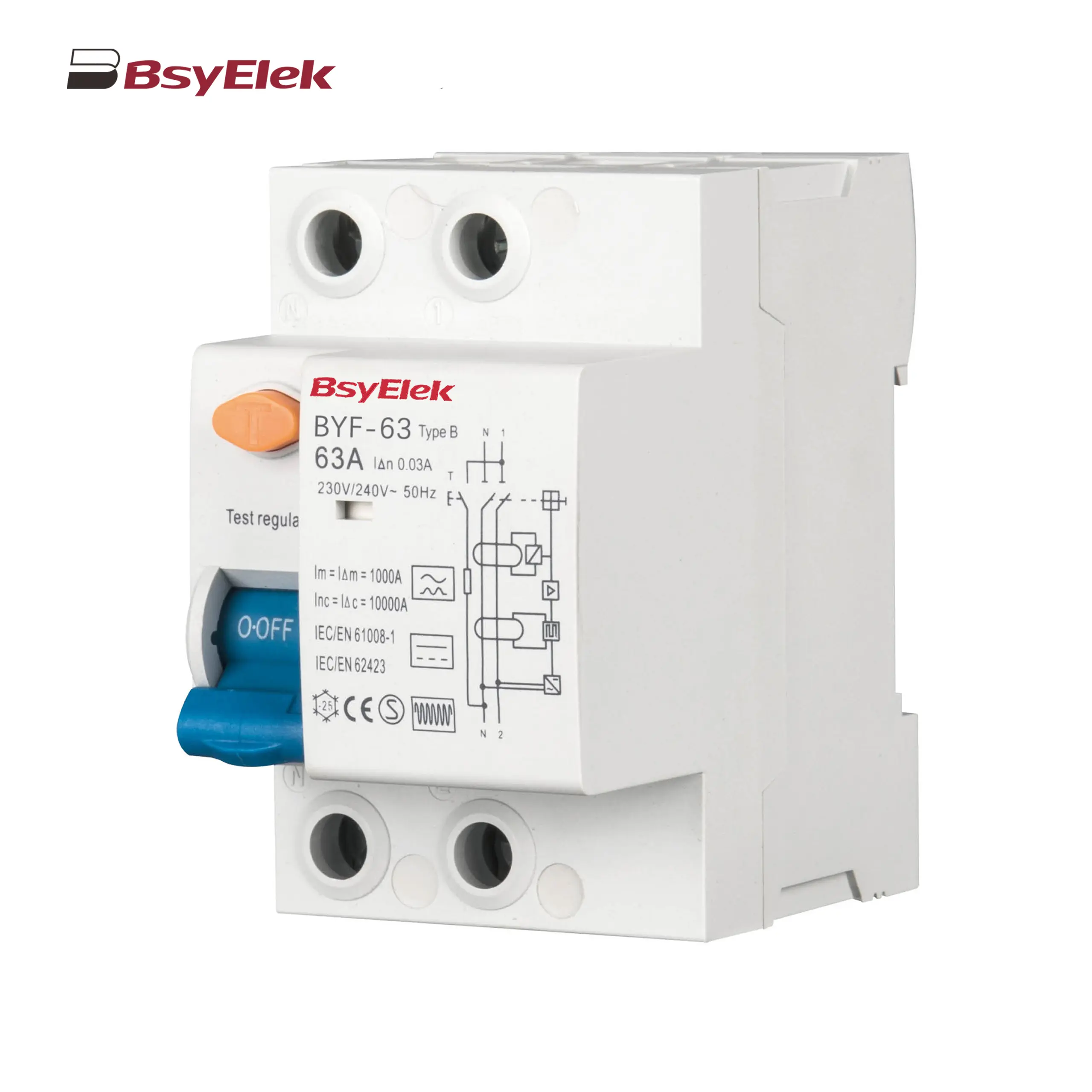

LWSF-125 125A Manual Changeover Switch BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device

BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device

BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device

BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link

BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link

BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link BYPV-ELR2 PV Isolator Switch with Enclosed Version

BYPV-ELR2 PV Isolator Switch with Enclosed Version BYPV-ELR1 PV Isolator Switch with Enclosed Version

BYPV-ELR1 PV Isolator Switch with Enclosed Version BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle

BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle BYPV-NL1 PV Isolator Switch with Lever Handle

BYPV-NL1 PV Isolator Switch with Lever Handle BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle

BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle PV-BY-01 30A/50A 1000V Photovoltaic Connector

PV-BY-01 30A/50A 1000V Photovoltaic Connector PV-BY-02 30A/50A 1500V Photovoltaic Connector

PV-BY-02 30A/50A 1500V Photovoltaic Connector PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector

PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector PV-BY-F01 30A 1500V Diode/Fuse Type Connector

PV-BY-F01 30A 1500V Diode/Fuse Type Connector PV-BY-T 50A 1500V T Type Branch Connector

PV-BY-T 50A 1500V T Type Branch Connector PV-BY-Y 30A 1500V Y Type Branch Connector

PV-BY-Y 30A 1500V Y Type Branch Connector PG Waterproof Cable Gland with Washer

PG Waterproof Cable Gland with Washer Photovoltaic Cable

Photovoltaic Cable HD11N Photovoltaic Knife Switch

HD11N Photovoltaic Knife Switch BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker

BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker

BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker BYM1E MCCB Electronic Type Molded Case Circuit Breaker

BYM1E MCCB Electronic Type Molded Case Circuit Breaker BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker

BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker BYW1 ACB Intelligent Universal Air Circuit Breaker

BYW1 ACB Intelligent Universal Air Circuit Breaker BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch

BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch Stainless Steel Hinge Type Electrical Box

Stainless Steel Hinge Type Electrical Box HA Waterproof Distribution Box

HA Waterproof Distribution Box HT Waterproof Distribution Box

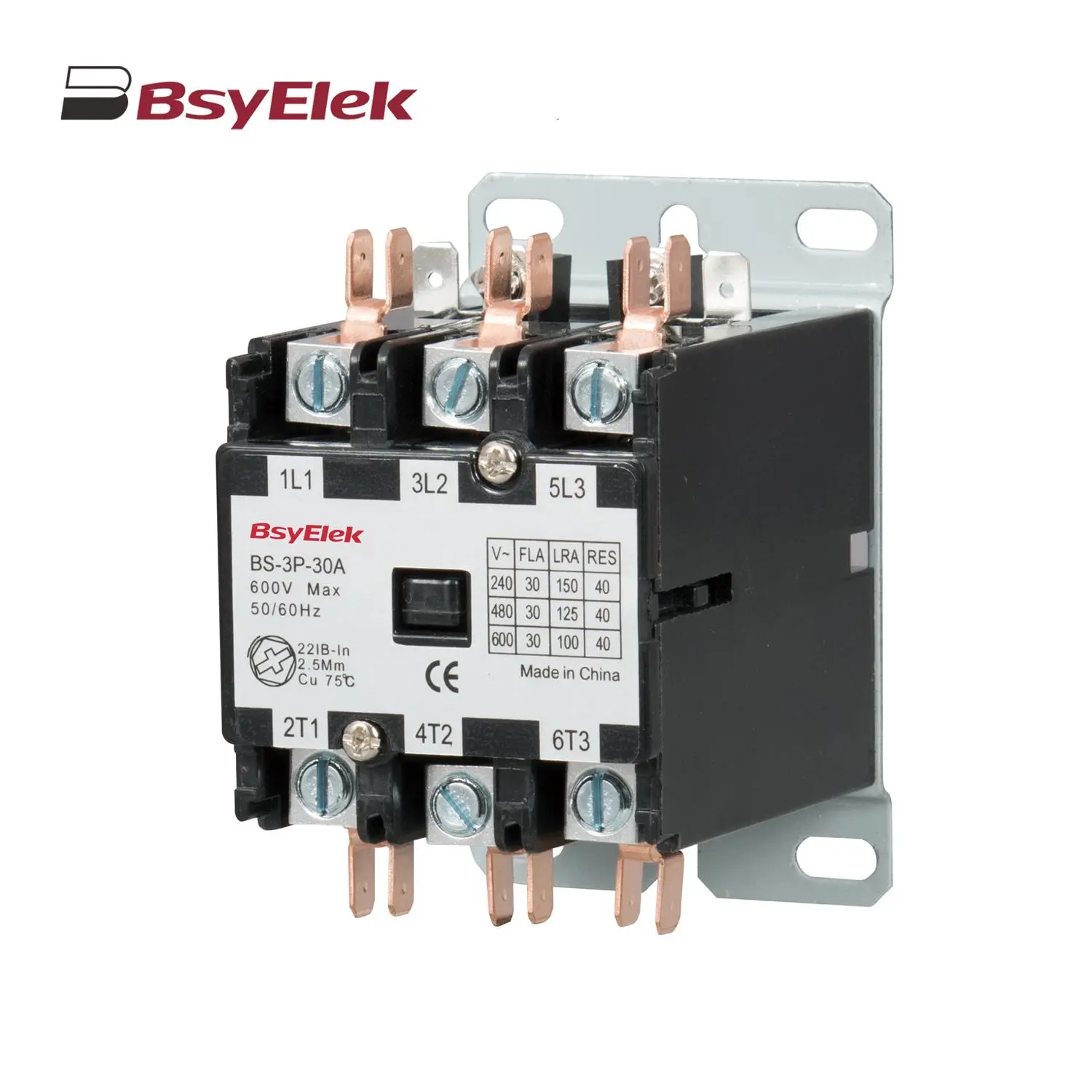

HT Waterproof Distribution Box BS Definite Purpose Magnetic AC Contactor

BS Definite Purpose Magnetic AC Contactor