7 Essential Tips to Choose the Right Waterproof Cable Gland for Your Projects

In today's increasingly complex electrical installations, the selection of a high-quality Waterproof Cable Gland has become more critical than ever. With forecasts indicating that the global market for cable management systems is expected to reach approximately $46 billion by 2025, ensuring the integrity and safety of electrical connections is paramount. Waterproof Cable Glands are essential components that safeguard against moisture, dust, and other environmental factors that can compromise the performance of electrical systems. According to industry reports, improper sealing and inadequate protection can lead to system failures and costly downtimes, affecting both operational efficiency and safety. Therefore, understanding the fundamental aspects of Waterproof Cable Glands, including their types, materials, and installation requirements, is vital for engineers and project managers looking to ensure long-term reliability and performance in their projects.

Understanding Waterproof Cable Gland Ratings and Standards

When selecting a waterproof cable gland for your projects, understanding the ratings and standards associated with these components is crucial.

Waterproof cable glands are classified based on their Ingress Protection (IP) rating, which indicates their ability to prevent the entry of water and dust.

The IP rating consists of two digits, with the first digit representing protection against solids and the second digit against liquids.

For instance, an IP68 rating signifies that the gland is dust-tight and can withstand continuous immersion in water beyond a specified depth.

In addition to IP ratings, it’s essential to consider other industry standards relevant to your specific application.

These include the National Electrical Manufacturers Association (NEMA) ratings in North America, which provide guidelines for the performance of enclosures in various environmental conditions.

Furthermore, certifications such as UL, CE, and RoHS ensure that the cable glands meet safety and quality requirements.

By familiarizing yourself with these standards, you can make informed decisions that enhance the reliability and durability of your project's electrical connections in demanding environments.

Assessing the Environmental Conditions for Your Project

When selecting the right waterproof cable gland for your project, understanding the environmental conditions is crucial. Different environments can significantly impact the performance and longevity of cable glands. For instance, if your installation is in a highly humid or wet area, you'll need to ensure that the gland offers a high ingress protection (IP) rating, such as IP68. This rating indicates that the gland can withstand prolonged exposure to water, making it ideal for outdoor applications or locations prone to flooding.

Additionally, consider temperature fluctuations and potential exposure to harsh chemicals. In environments where temperatures can soar or plummet, a cable gland rated for extreme conditions will prevent premature failure. Similarly, if your project involves exposure to corrosive agents, opt for cable glands made from durable materials like stainless steel or reinforced plastics. By assessing the specific environmental factors associated with your project, you can make an informed decision that enhances the reliability and safety of your electrical installations.

Environmental Conditions Impact on Waterproof Cable Gland Selection

This chart illustrates the importance of different environmental conditions when choosing a waterproof cable gland, showing factors like humidity, temperature, exposure to chemicals, and UV light.

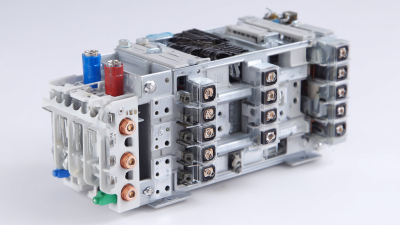

Selecting the Right Material for Durability and Functionality

Selecting the right material for a waterproof cable gland is crucial for ensuring both durability and functionality in various projects. Materials such as plastics have traditionally dominated the market due to their affordability and versatility. However, rising environmental awareness has prompted a shift towards more sustainable materials that not only reduce ecological impact but also offer comparable durability. For instance, innovative polymer designs are emerging, allowing for enhanced performance in extreme conditions while being environmentally friendly.

In recent developments, research teams have focused on functionalized polymer molecular structures to optimize materials for specific applications, such as lithium metal batteries with improved longevity. This trend reflects a broader commitment within the industry to prioritize sustainable design solutions. By doing so, designers can significantly influence the environmental footprint of products right from the design stage, emphasizing efficiency alongside durability and responsible sourcing. This proactive approach not only meets market demands but also aligns with the growing consumer preference for eco-friendly alternatives.

7 Essential Tips to Choose the Right Waterproof Cable Gland for Your Projects

| Tip |

Description |

Material Types |

Environmental Suitability |

IP Ratings |

| 1. Consider the Environment |

Evaluate the location’s exposure to water, humidity, and other environmental factors. |

Plastic, Stainless Steel, Brass |

Indoor/Outdoor conditions, High humidity areas |

IP66, IP67, IP68 |

| 2. Identify Cable Types |

Ensure the cable gland is compatible with the type of cables being used. |

Single core, Multi-core |

Electrical installations, Signal transmission |

IP65, IP67 |

| 3. Assess Mechanical Stability |

Choose a gland that can withstand mechanical strain and stress. |

Heavy-duty plastic, Metal |

Industrial environments, Vibration-prone areas |

IP66 |

| 4. Evaluate Temperature Ranges |

Ensure the materials chosen can operate effectively within the temperature range. |

Silicone, PVC, Rubber |

Extreme environments, Controlled conditions |

IP67 |

| 5. Check the Sealing Method |

Choose a gland that offers effective sealing against water ingress. |

O-ring sealed, Mechanical seal |

Outdoor installations, Marine environments |

IP68 |

| 6. Ensure Compliance with Standards |

Select products that meet international safety standards. |

UL listed, IEC compliant |

Commercial and industrial standards |

IP65, IP66 |

| 7. Factor in Installation Ease |

Choose a design that is easy to install and reduces labor time. |

Quick-mount, Standard screw-fit |

Projects requiring quick turnarounds |

IP66 |

Evaluating Size and Thread Types for Optimal Compatibility

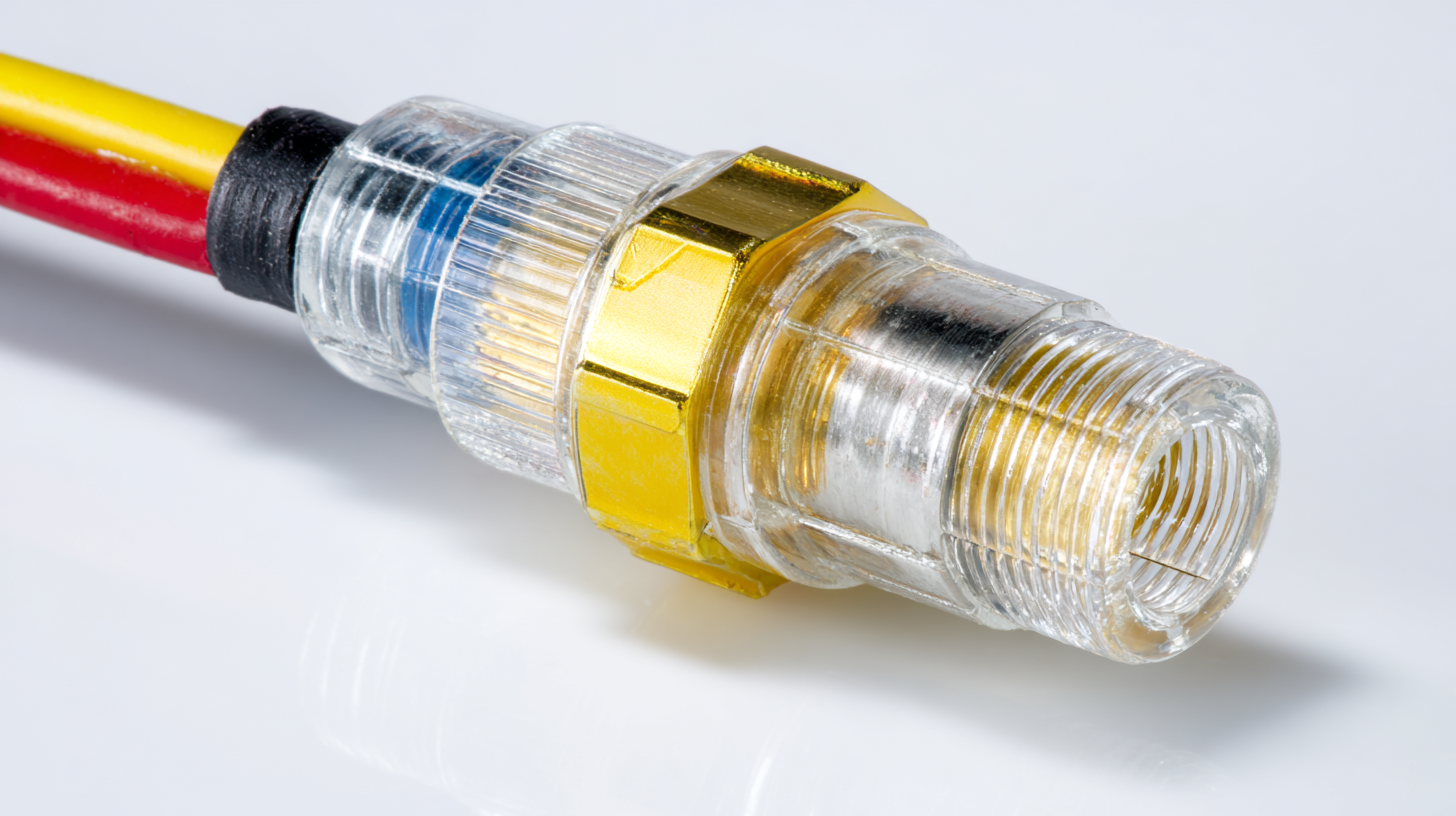

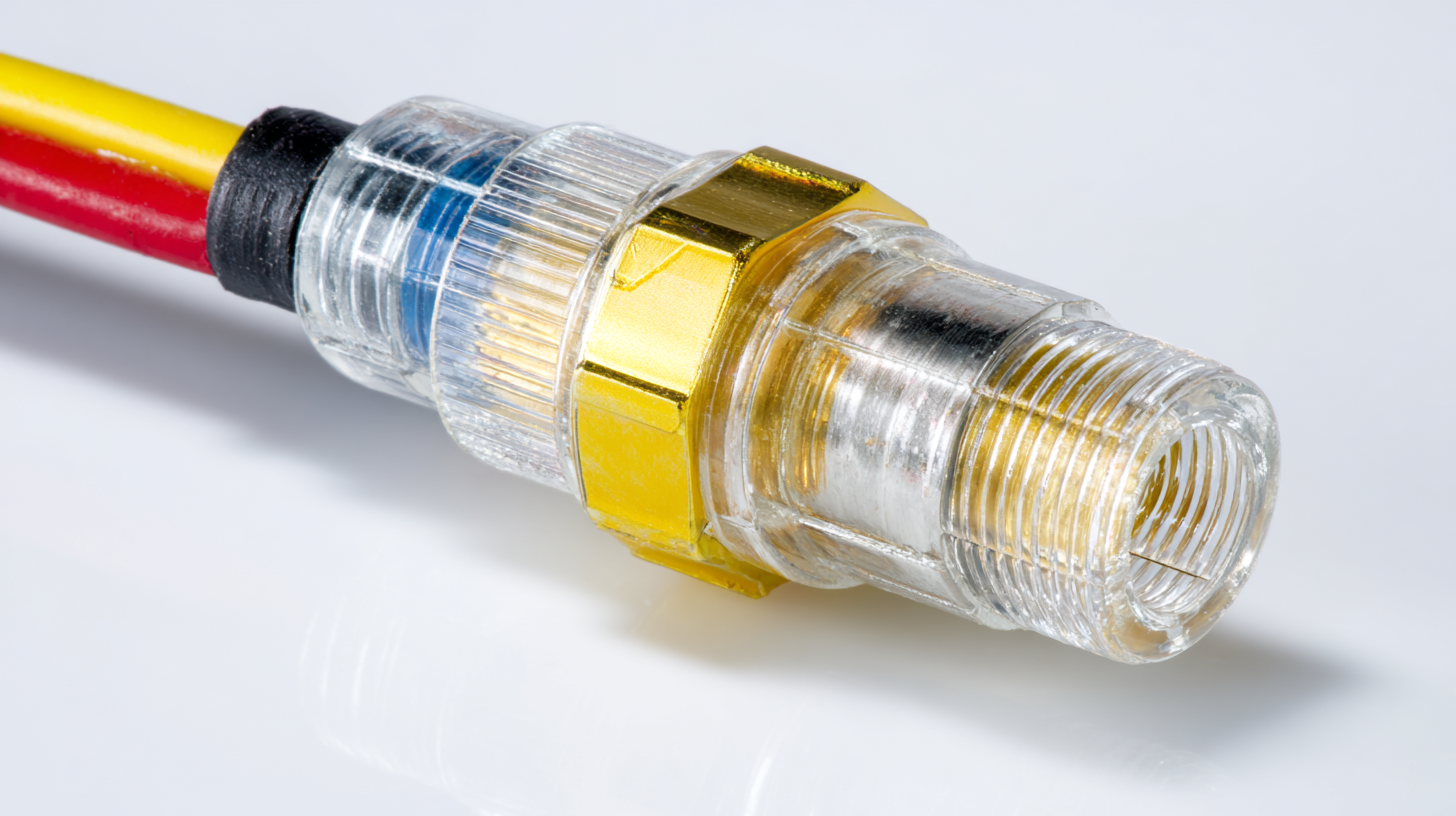

When selecting the right waterproof cable gland for your project, evaluating the size and thread types is crucial for ensuring optimal compatibility with your cabling and enclosures. The size of the gland must align with the diameter of the cable it will accommodate. A tight fit is essential to maintain the integrity of the waterproof seal and prevent moisture ingress. Manufacturers often provide size charts, so take the time to measure your cable accurately to ensure a suitable match for the chosen gland.

Thread types also play a significant role in achieving a secure fit. There are several thread standards available, such as metric, NPT, and PG, each with its specific application and fitting requirements. Choosing the correct thread type not only facilitates proper installation but also prevents any potential damage to the cable insulation when tightening the gland. Be sure to check the threading compatibility with your enclosure to avoid any mismatches that could compromise the effectiveness of the waterproof seal. By carefully considering both size and thread type, you can select a cable gland that meets the demands of your environment and project specifications.

Exploring Additional Features for Enhanced Performance

When selecting waterproof cable glands, it’s essential to consider additional features that can enhance performance and longevity. For instance, features such as integrated strain relief and sealing properties play a crucial role in protecting cables from environmental factors. According to a recent industry report by MarketsandMarkets, the cable gland market is projected to grow from $2.5 billion in 2020 to $3.6 billion by 2025, reflecting the increasing demand for reliable waterproof solutions.

Investing in high-quality materials is another tip to ensure optimal performance. Opt for cable glands made from materials like polyamide or stainless steel, which exhibit superior resistance to corrosion and impact. These materials not only improve durability but also contribute to the overall safety of electrical installations in harsh environments. Research indicates that installations using advanced waterproof cable glands can reduce maintenance costs by up to 30%, highlighting the long-term benefits of making informed choices.

Additionally, consider the ingress protection (IP) ratings of the cable glands. Choosing an IP68-rated gland can provide better assurance against water and dust ingress, crucial in demanding applications such as marine or industrial sectors. Notably, manufacturers are now offering custom designs that cater to specific environmental conditions, enabling projects to operate seamlessly while minimizing failures due to environmental exposure.

Home

About Us

Products

Terminal Power Distribution Electric

AC Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

MCB Accessories

Main Switch

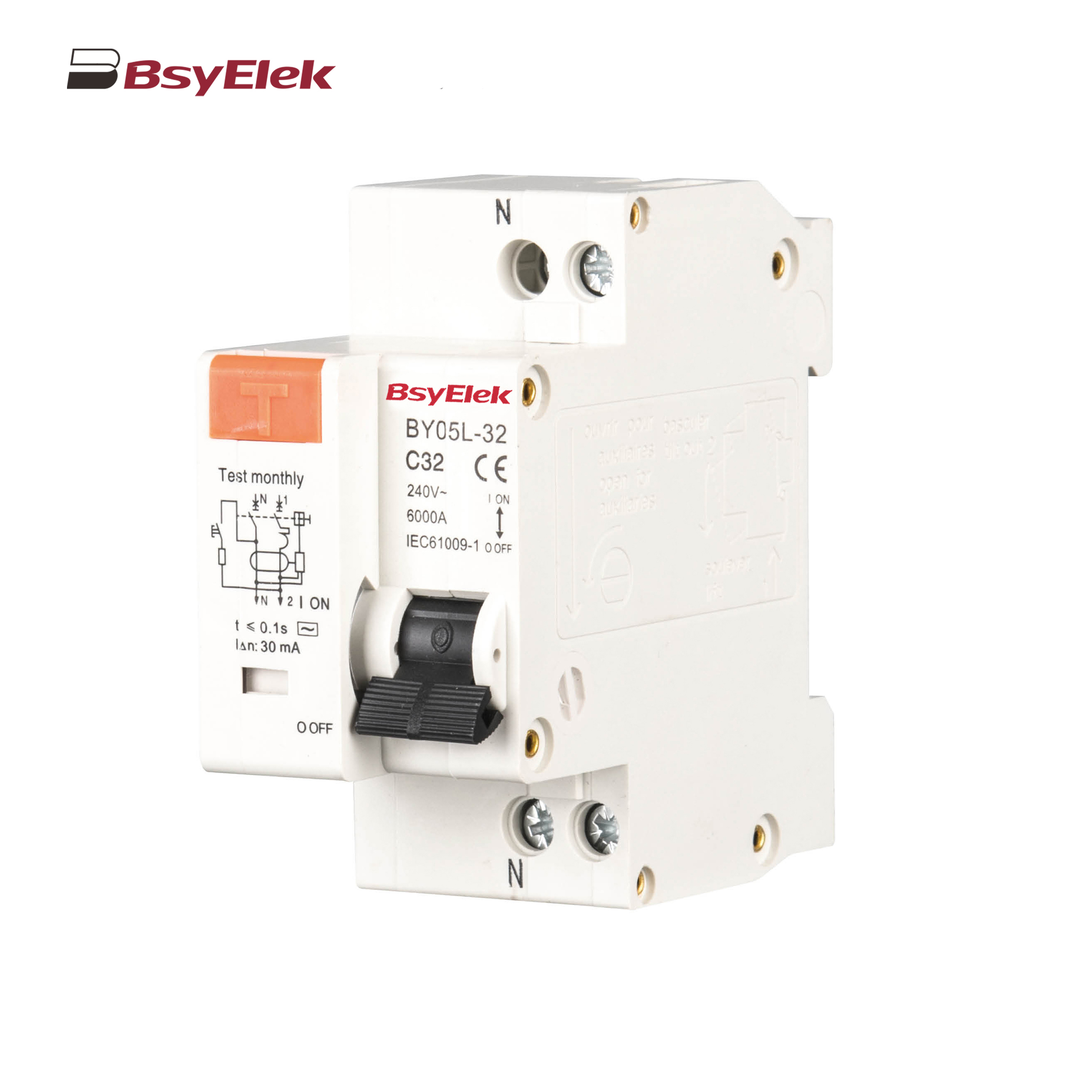

RCBO RCCB

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

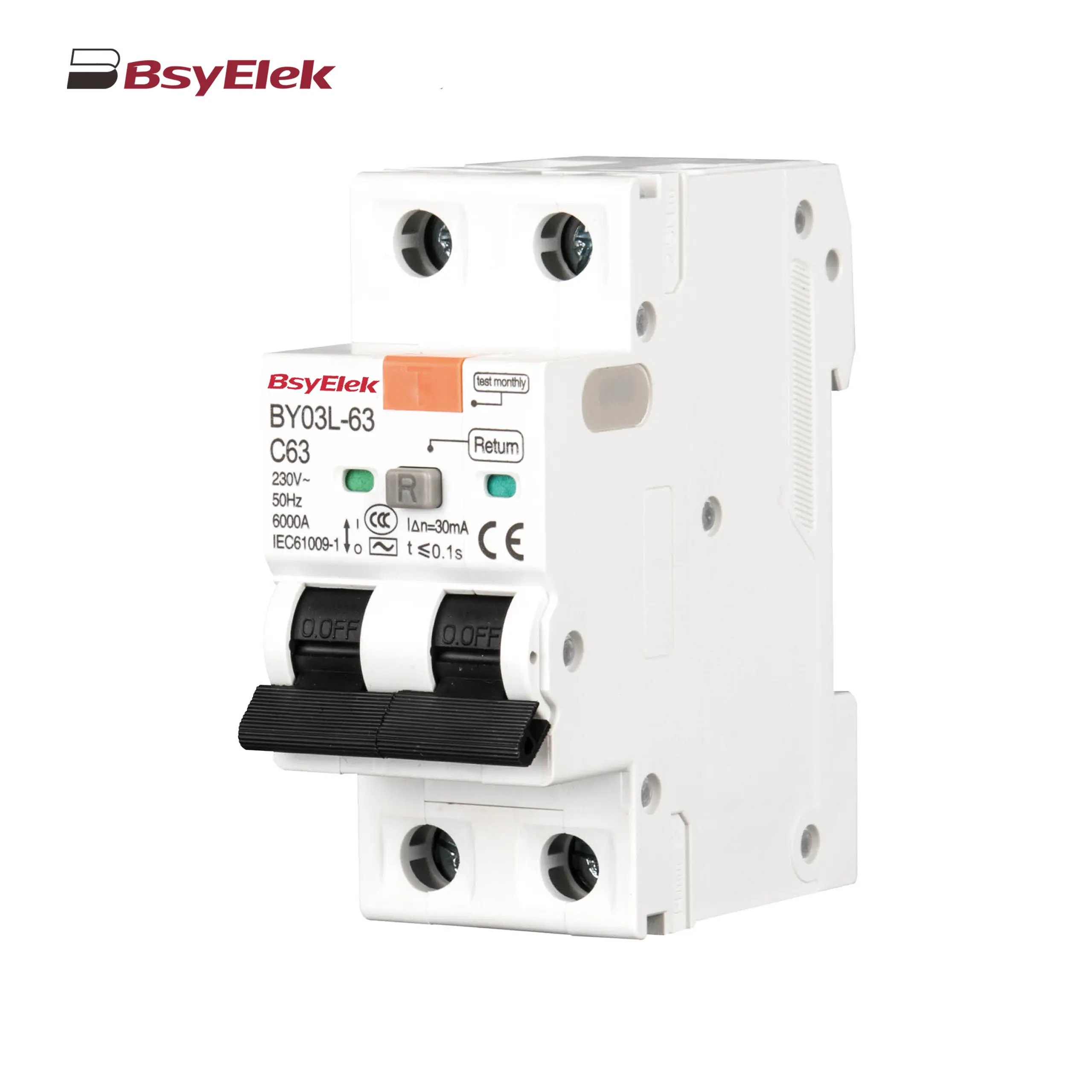

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

Resettable Overvoltage and Undervoltage Protector

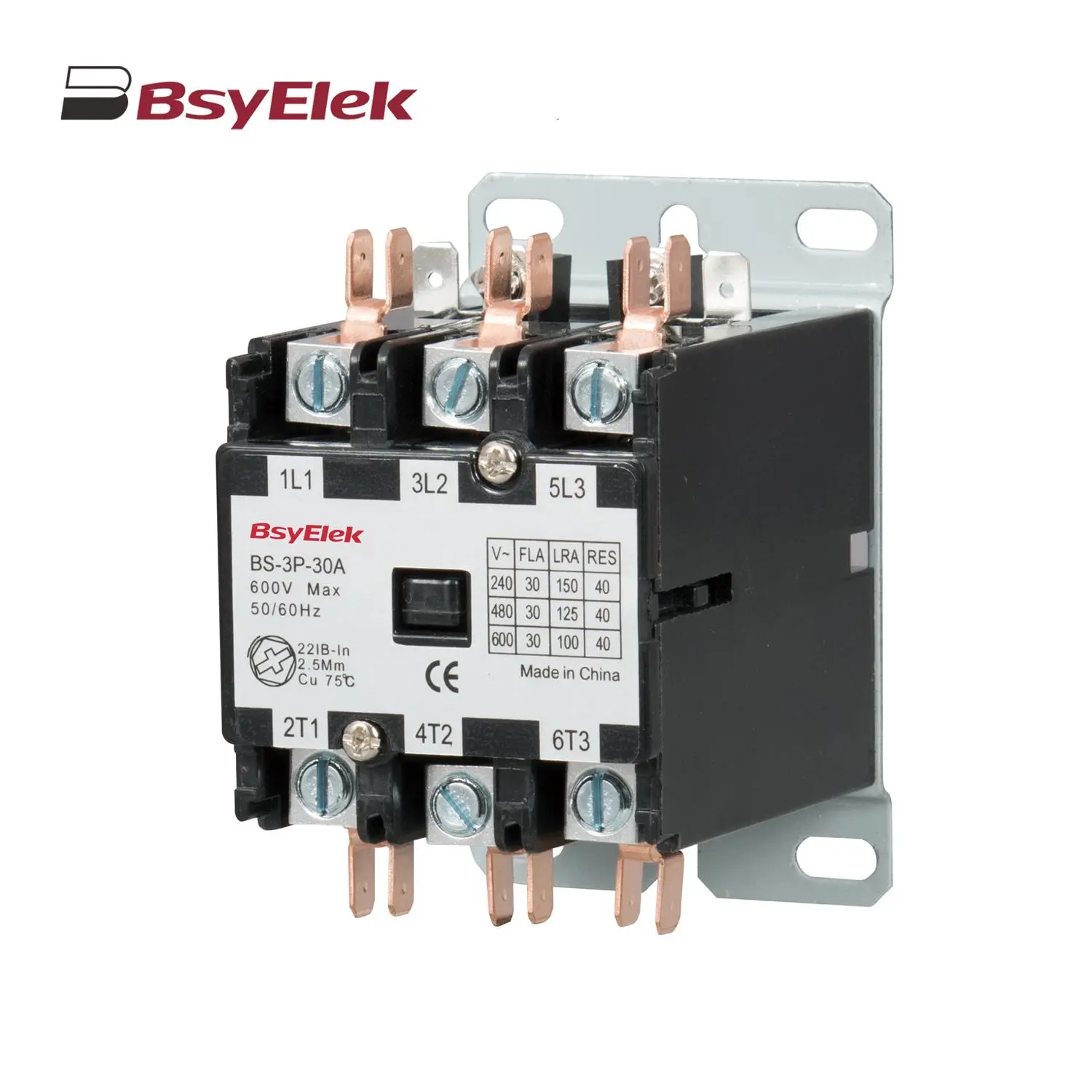

AC Contactor

AC Surge Protective Device

Changeover Switch

Photovoltaic System Protection

DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

RCD

DC Surge Protective Device

DC Fuse

PV Isolator Switch

PV Connector

Cable Gland

PV Cable

PV Knife Switch

DC Molded Case Circuit Breaker

Industrial Power Distribution Electric

Distribution Box

Air Conditioning System

Definite Purpose Magnetic Contactor

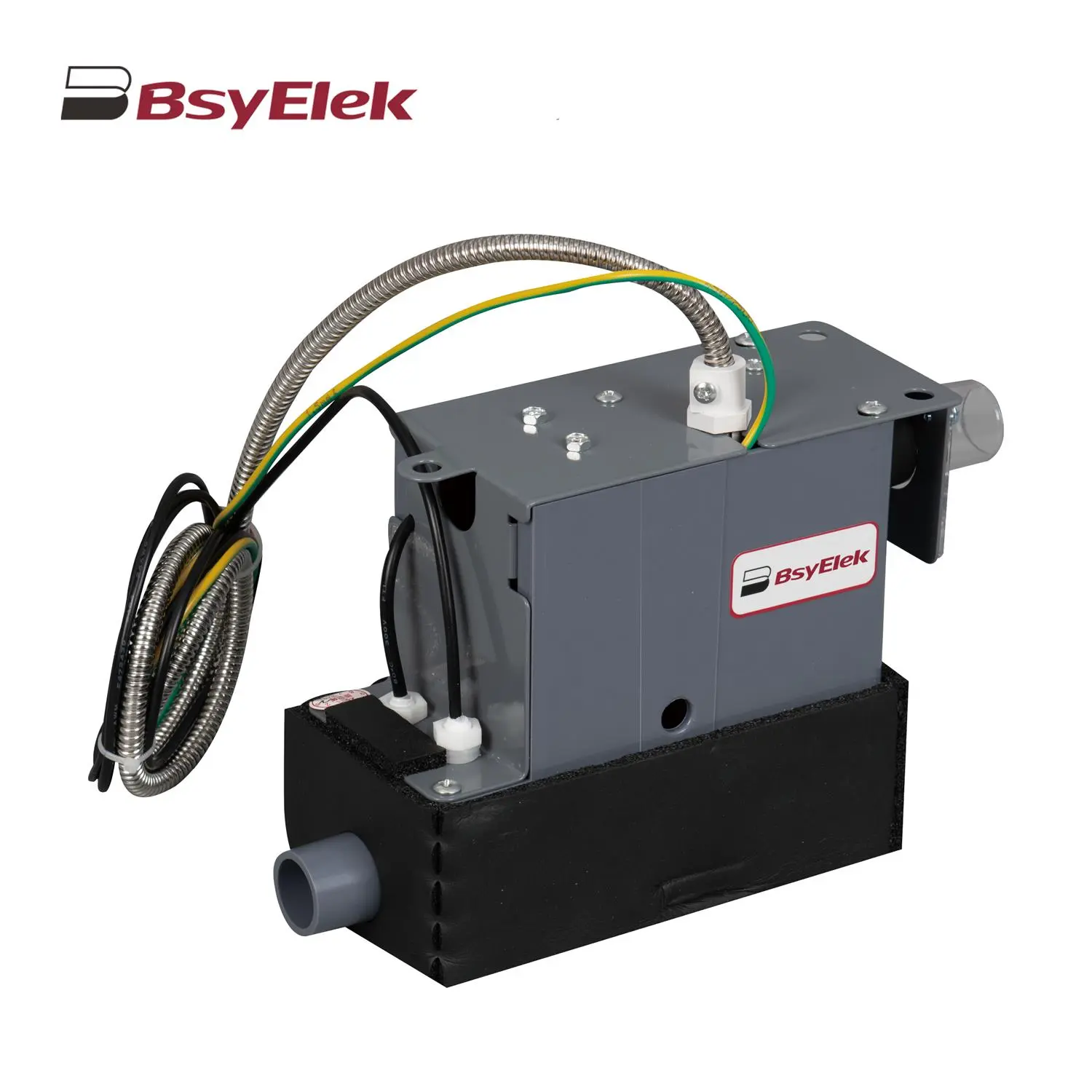

Condensate Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-24B/40B 10M Split Type Drainage Pump

BY-24B/40B 10M Split Type Drainage Pump

BY-100L 2M Drainage Pump of Air Conditioner

BY-100L 2M Drainage Pump of Air Conditioner

BY-360L 6M Large Displacement Drainage Pump

BY-360L 6M Large Displacement Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

News

Top Blog

Company News

Industry Dynamics

What is a miniature circuit breaker (MCB)?

PG Series Waterproof Cable Glands with Washer for Harsh Environments

LWSF-125 125A Manual Changeover Switch ensures reliable power transfer

BYX2 AC contactor series: reliable power control for modern electrical systems

High-performance 1000V DC fuse holder optimizes solar photovoltaic system protection

BY07L-63 Residual Current Circuit Breaker Ensures Global Electrical Safety

BYQ5 ATS Isolation Dual Power Automatic Transfer Switch

BY19G 63A Manual Changeover Switch: Features and Benefits

Support

Blog

Contact Us

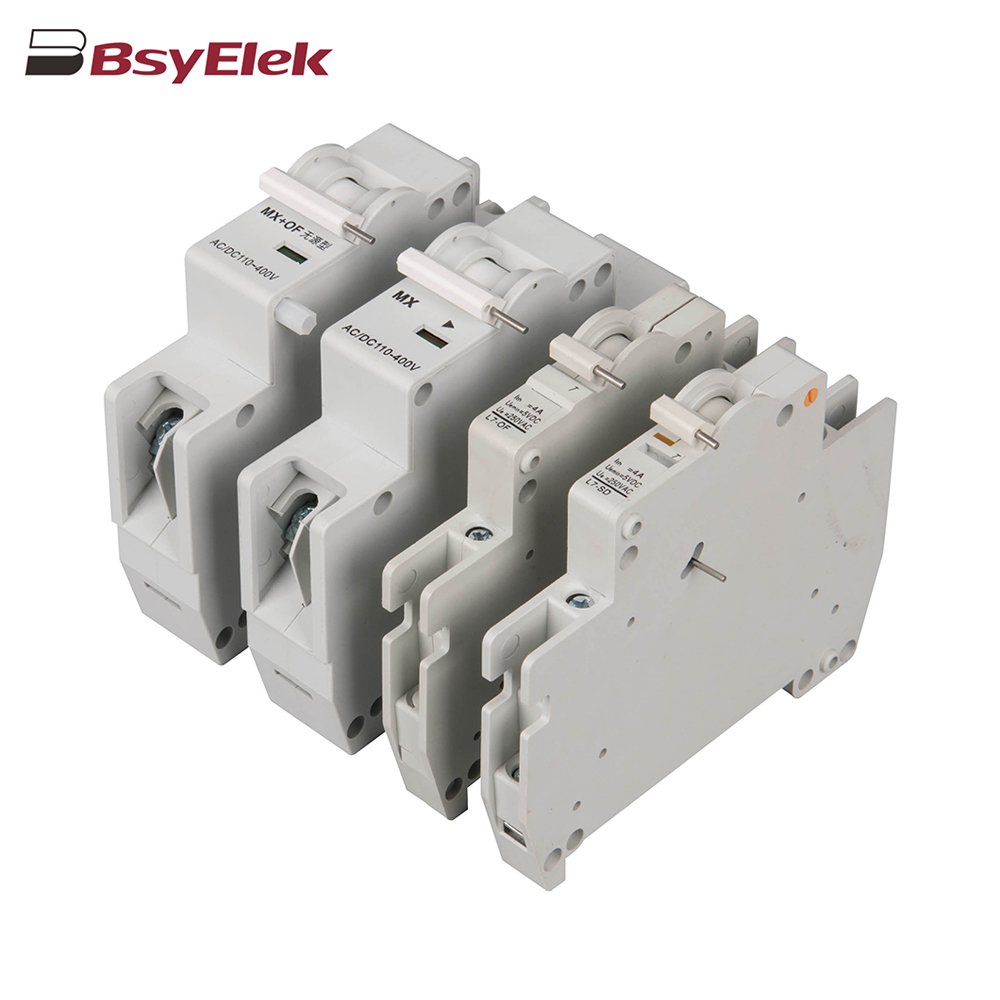

OF SD MX OF MCB Miniature Circuit Breaker Accessories

OF SD MX OF MCB Miniature Circuit Breaker Accessories BYG1-125 Main Switch MCB Isolator Switch

BYG1-125 Main Switch MCB Isolator Switch BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector

BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector

BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector BYX2 6-95A AC Contactor

BYX2 6-95A AC Contactor BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device

BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device

BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device

BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device BY19G 63A Manual Changeover Switch

BY19G 63A Manual Changeover Switch LWSF-125 125A Manual Changeover Switch

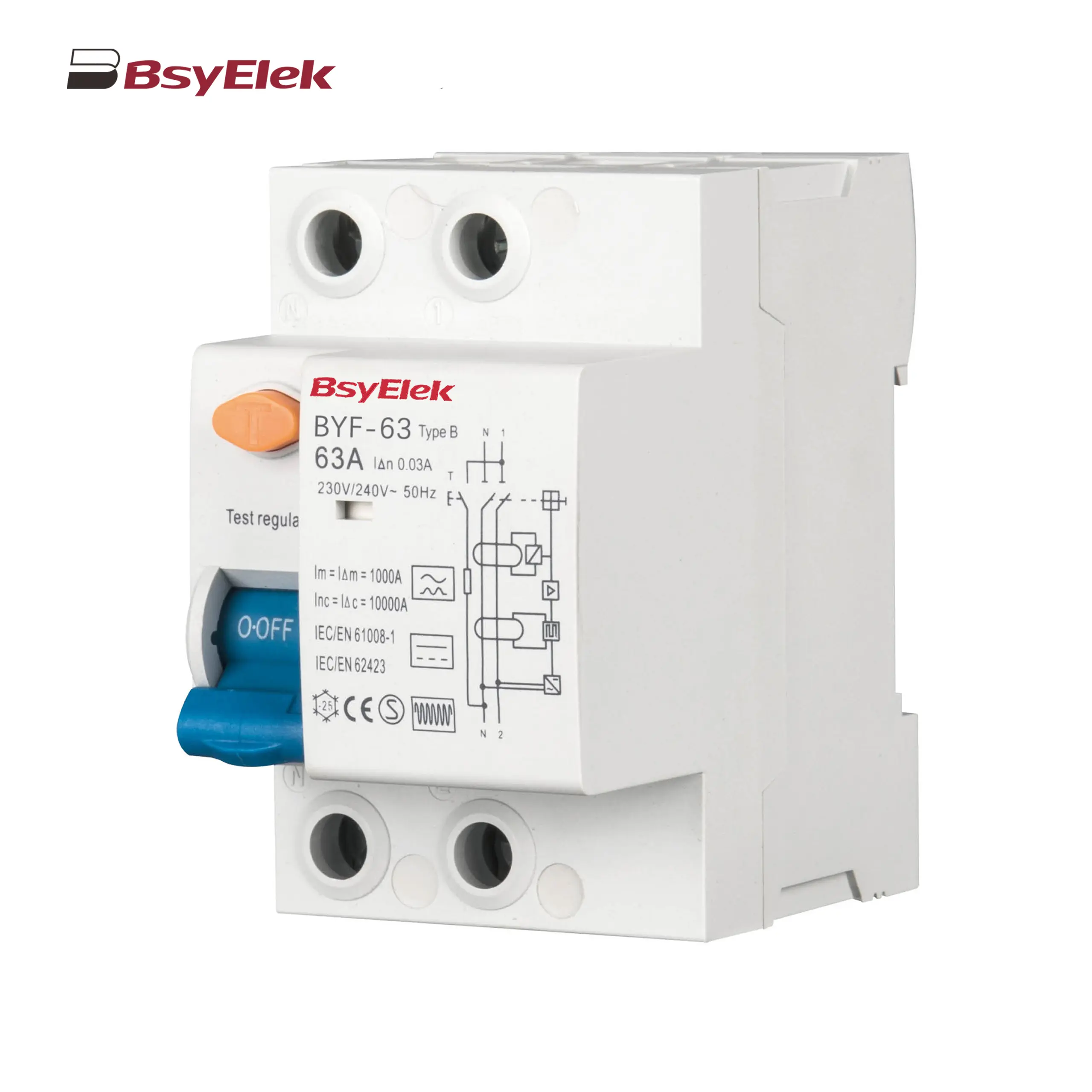

LWSF-125 125A Manual Changeover Switch BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device

BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device

BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device

BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link

BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link

BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link BYPV-ELR2 PV Isolator Switch with Enclosed Version

BYPV-ELR2 PV Isolator Switch with Enclosed Version BYPV-ELR1 PV Isolator Switch with Enclosed Version

BYPV-ELR1 PV Isolator Switch with Enclosed Version BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle

BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle BYPV-NL1 PV Isolator Switch with Lever Handle

BYPV-NL1 PV Isolator Switch with Lever Handle BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle

BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle PV-BY-01 30A/50A 1000V Photovoltaic Connector

PV-BY-01 30A/50A 1000V Photovoltaic Connector PV-BY-02 30A/50A 1500V Photovoltaic Connector

PV-BY-02 30A/50A 1500V Photovoltaic Connector PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector

PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector PV-BY-F01 30A 1500V Diode/Fuse Type Connector

PV-BY-F01 30A 1500V Diode/Fuse Type Connector PV-BY-T 50A 1500V T Type Branch Connector

PV-BY-T 50A 1500V T Type Branch Connector PV-BY-Y 30A 1500V Y Type Branch Connector

PV-BY-Y 30A 1500V Y Type Branch Connector PG Waterproof Cable Gland with Washer

PG Waterproof Cable Gland with Washer Photovoltaic Cable

Photovoltaic Cable HD11N Photovoltaic Knife Switch

HD11N Photovoltaic Knife Switch BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker

BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker

BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker BYM1E MCCB Electronic Type Molded Case Circuit Breaker

BYM1E MCCB Electronic Type Molded Case Circuit Breaker BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker

BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker BYW1 ACB Intelligent Universal Air Circuit Breaker

BYW1 ACB Intelligent Universal Air Circuit Breaker BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch

BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch Stainless Steel Hinge Type Electrical Box

Stainless Steel Hinge Type Electrical Box HA Waterproof Distribution Box

HA Waterproof Distribution Box HT Waterproof Distribution Box

HT Waterproof Distribution Box BS Definite Purpose Magnetic AC Contactor

BS Definite Purpose Magnetic AC Contactor