Understanding Disconnect Switches: Essential Safety Features for Your Electrical System

In the realm of electrical safety and system reliability, the importance of disconnect switches cannot be overstated. According to the National Fire Protection Association (NFPA), improper electrical system maintenance contributes to about 39% of electrical-related fires, underscoring the need for effective safety mechanisms. Disconnect switches serve as vital components that enable the safe isolation of circuits for maintenance and emergency procedures, thereby minimizing the risk of accidents and equipment damage. Moreover, a report by the International Electrotechnical Commission (IEC) highlights that up to 70% of electrical system outages can be traced back to inadequate isolation protocols. Understanding the essential safety features of disconnect switches is critical for safeguarding infrastructure, ensuring regulatory compliance, and enhancing operational efficiency. As such, organizations must prioritize the integration and understanding of these devices within their electrical systems to promote a safer working environment.

How Disconnect Switches Enhance Electrical Safety in Your System

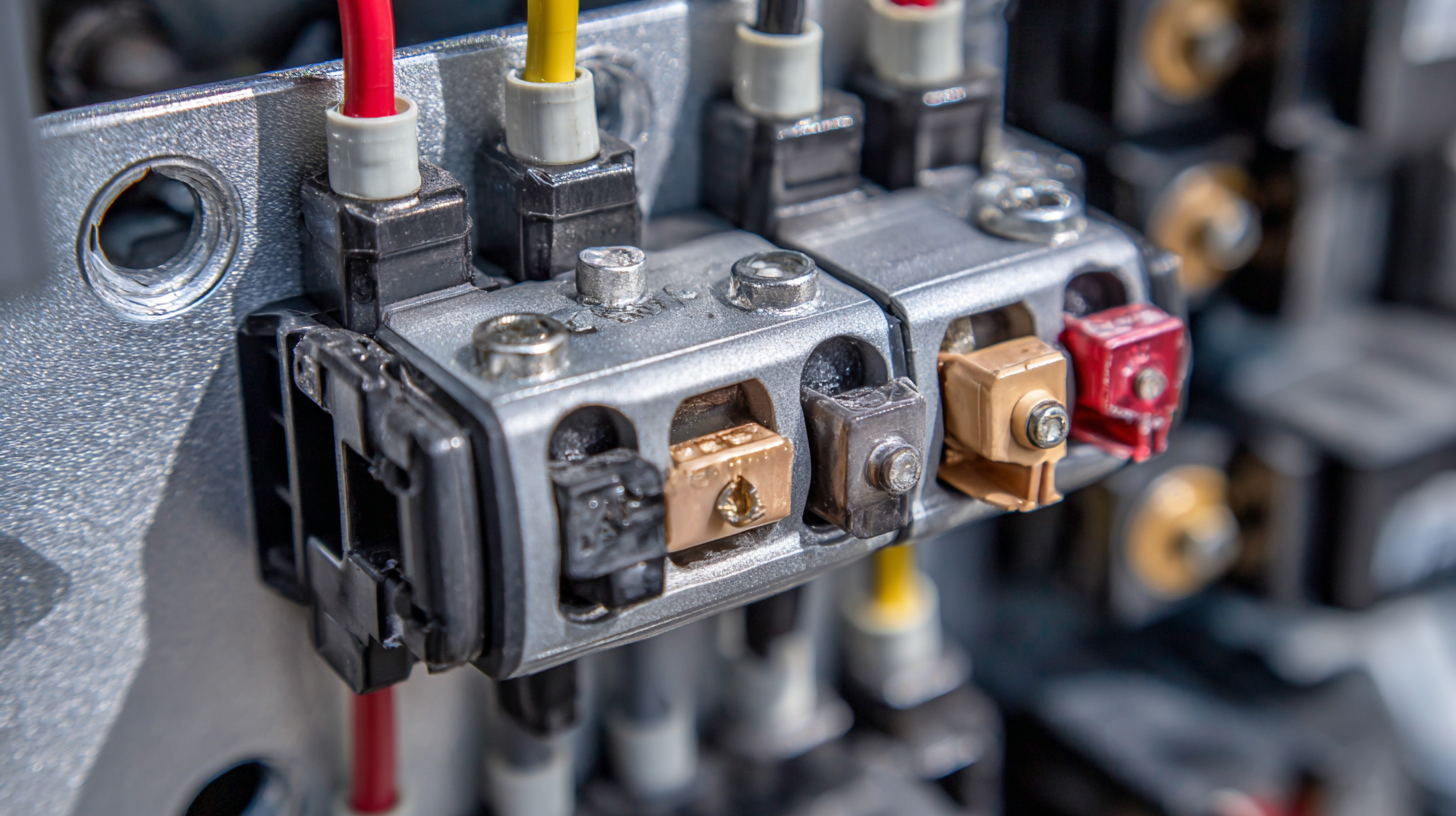

Disconnect switches are crucial components in enhancing the safety of electrical systems. By providing a reliable method to safely isolate portions of the electrical network, these switches significantly reduce the risk of electric shocks and equipment damage during maintenance or emergencies. As the demand for electric vehicle (EV) charging stations and renewable energy infrastructure expands, the significance of disconnect switches becomes even more pronounced. Electric vehicle charging systems, in particular, require robust safety mechanisms to ensure user protection and grid stability.

The integration of disconnect switches in various applications supports a safer electrical environment. With their ability to swiftly disconnect power during overloads or faults, these devices not only protect humans but also safeguard sensitive equipment against potential damage. The ongoing innovation in switching technologies, driven by growing sectors such as EV and renewable energy, highlights the necessity of incorporating effective disconnect solutions as a fundamental safety feature in modern electrical designs. As industries evolve, the role of these switches in maintaining safety and reliability will be increasingly paramount.

Understanding Disconnect Switches: Essential Safety Features for Your Electrical System

| Feature |

Description |

Safety Benefit |

Application |

| Manual Operation |

Allows users to easily disconnect power from electrical systems. |

Enhances safety during maintenance and repairs. |

Industrial equipment, HVAC systems. |

| Lockable Mechanism |

Can be locked in the 'off' position to prevent unauthorized access. |

Minimizes risk of accidental energization. |

Electrical panels, service disconnects. |

| Multiple Poles |

Can disconnect multiple circuits simultaneously. |

Provides comprehensive safety for three-phase systems. |

Factories, distribution boards. |

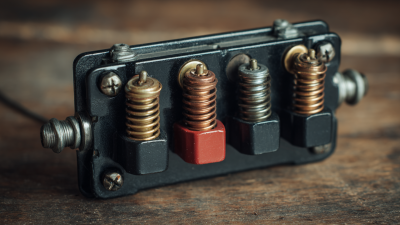

| Visible Blade Design |

Blades are visible when in the 'off' position. |

Confirms disconnection status at a glance. |

Service entrances, solar power systems. |

| Weatherproof Housing |

Designed for outdoor conditions. |

Protects internal components from the elements. |

Remote installations, outdoor electrical systems. |

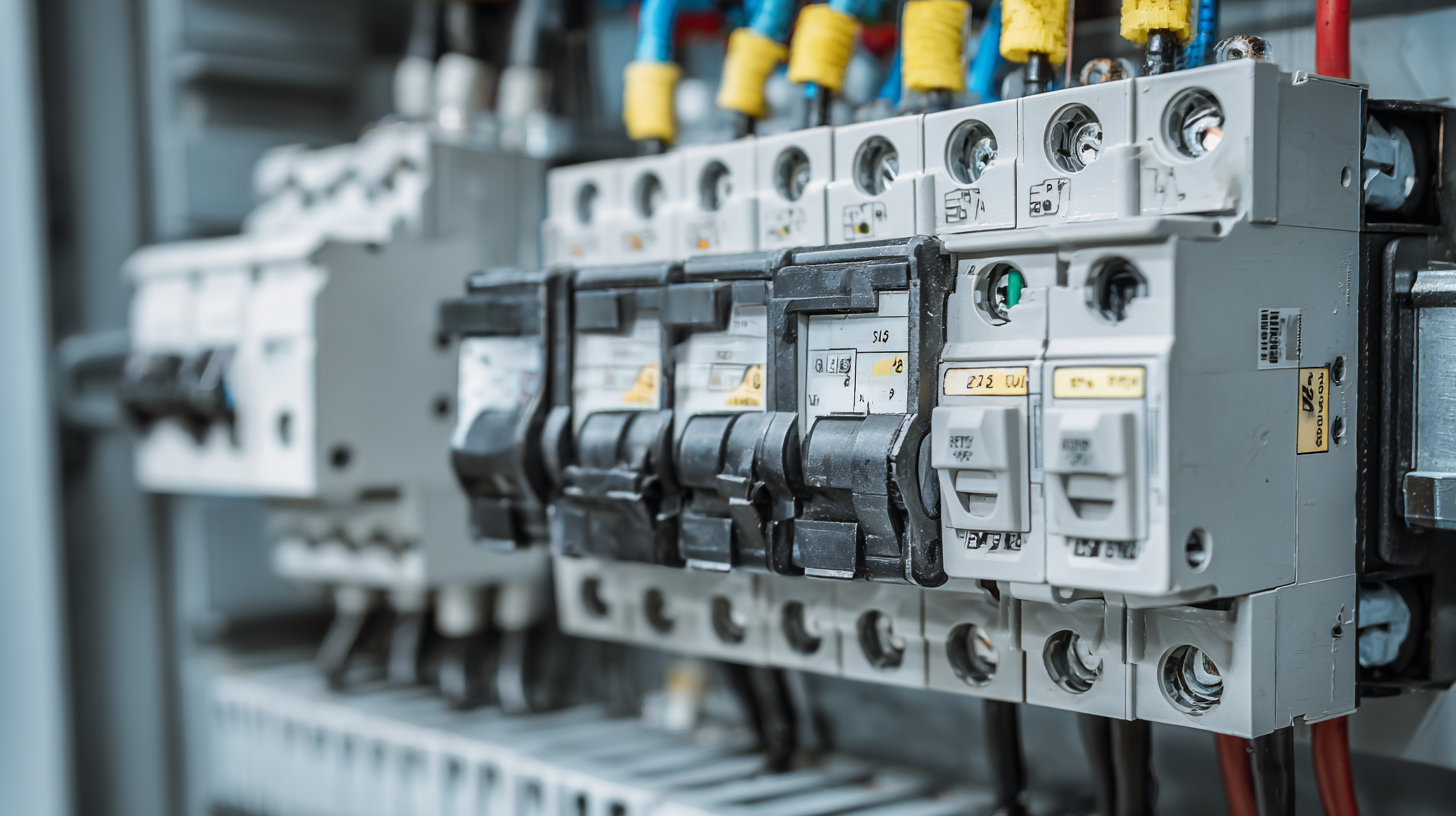

Key Features to Look for When Selecting a Disconnect Switch

When selecting a disconnect switch for your electrical system, understanding the key features is crucial for ensuring safety and efficiency. One of the most important features to consider is the switch's rated voltage and current. According to the National Electrical Manufacturers Association (NEMA), disconnect switches should be able to handle both the maximum voltage and the load current to prevent overheating or failure.

Another critical aspect is the type of enclosure used. A NEMA-rated enclosure provides protection from environmental factors such as dust and moisture, which can significantly affect the switch's performance. Options range from indoor to outdoor ratings, with IP65 being widely recognized for its robust protection against water and dust penetration.

Tips: When choosing a disconnect switch, always check the manufacturer's specifications for compatibility with your existing system. Additionally, look for models equipped with visible disconnect features, allowing for quick identification of the switch position. Regular maintenance and inspection are vital, as highlighted by the IEEE standards, recommending scheduled checks to enhance the longevity and reliability of your electrical components.

Step-by-Step Guide to Installing a Disconnect Switch Safely

Disconnect switches play a crucial role in enhancing electrical safety by providing a means to isolate a circuit during maintenance or emergencies. When installing a disconnect switch, it’s essential to follow a clear, step-by-step approach to ensure effective and safe operation. First, locating an appropriate installation site is critical; it should be accessible and comply with local electrical codes. According to the National Fire Protection Association (NFPA), more than 30% of electrical fires are linked to improper installations. By ensuring that disconnection points are readily available, the risks associated with delayed intervention can be substantially reduced.

Disconnect switches play a crucial role in enhancing electrical safety by providing a means to isolate a circuit during maintenance or emergencies. When installing a disconnect switch, it’s essential to follow a clear, step-by-step approach to ensure effective and safe operation. First, locating an appropriate installation site is critical; it should be accessible and comply with local electrical codes. According to the National Fire Protection Association (NFPA), more than 30% of electrical fires are linked to improper installations. By ensuring that disconnection points are readily available, the risks associated with delayed intervention can be substantially reduced.

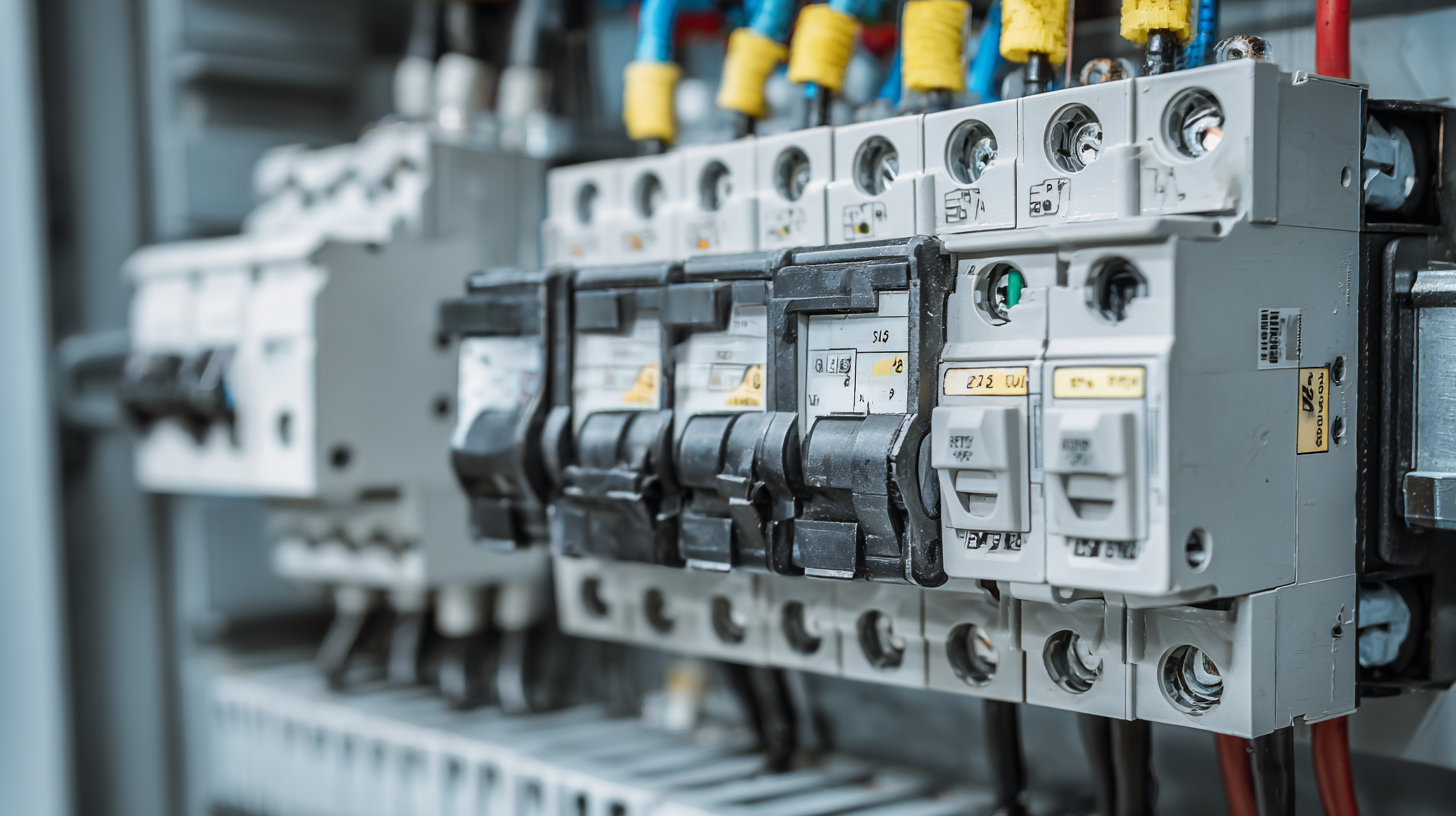

Once the location is determined, the installation process begins with the proper selection of tools and materials, including the disconnect switch itself, mounting hardware, and circuit breakers. Industry reports indicate that a correctly installed disconnect switch can minimize downtime by up to 20% during maintenance tasks, thereby improving operational efficiency. Connecting wires according to the manufacturer’s instructions and adhering to safety standards, such as the National Electrical Code (NEC), is essential in preventing electrical hazards. Regular inspection and maintenance of the disconnect switch will further ensure its reliability, safeguarding both personnel and equipment from potential electrical failures.

Common Mistakes to Avoid When Using Disconnect Switches

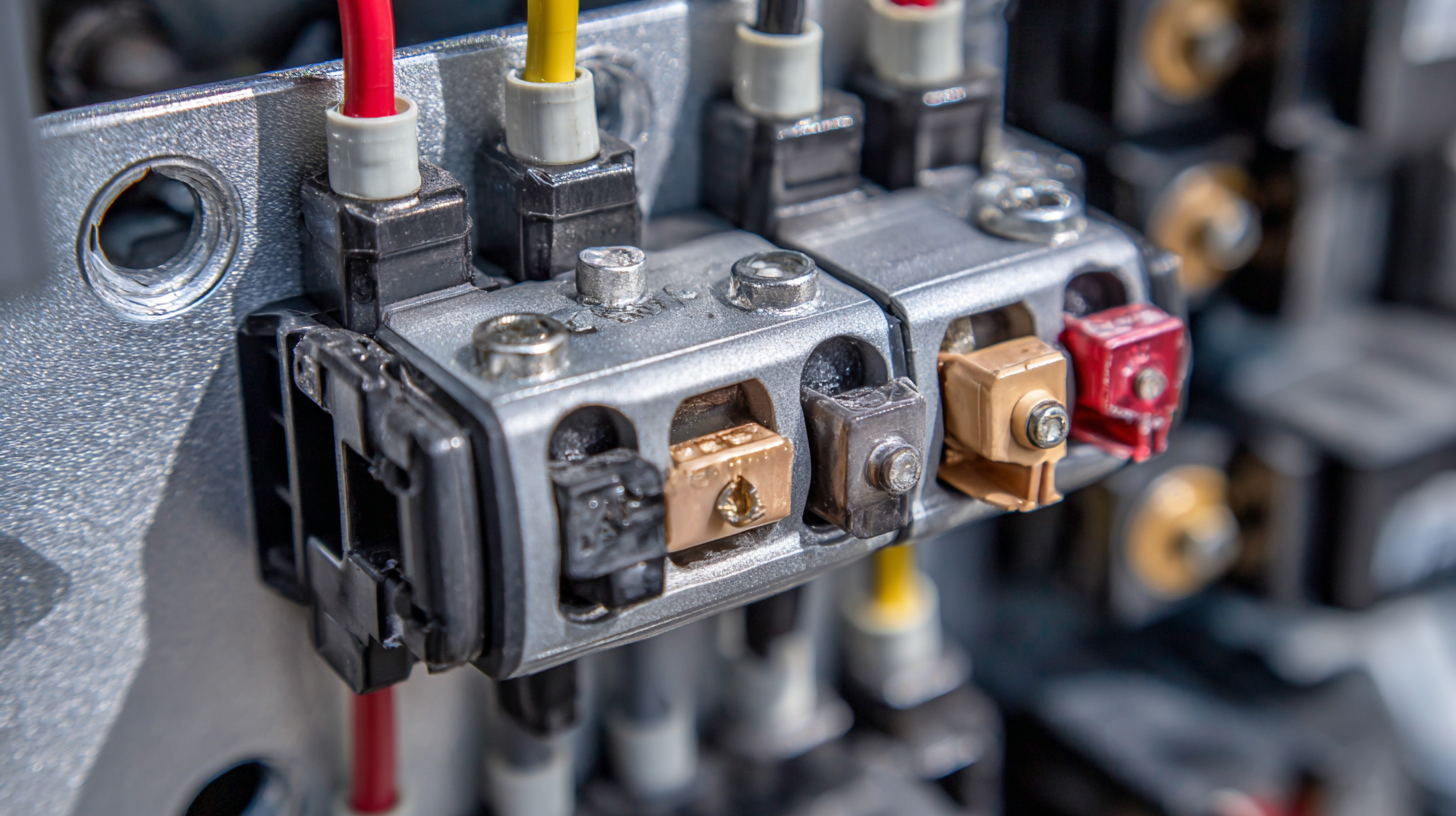

When using disconnect switches, avoiding common mistakes is crucial for ensuring safety and efficiency in your electrical system. One prevalent error is neglecting to verify the switch's operational status before maintenance or repairs. Failing to confirm that the switch is indeed open can lead to accidental electrocution or equipment damage. Always check and test the functionality of the disconnect switch to ensure it properly isolates the electrical components.

Another significant mistake is overlooking the importance of proper labeling and signage. It is vital to clearly mark disconnect switches with their function and load characteristics. This not only aids in quick identification during emergencies but also helps workers understand the system better, thereby reducing the chances of operational errors. Regular training and reminders about proper use and safety practices concerning disconnect switches can help mitigate these risks, fostering a safer working environment.

Understanding Disconnect Switches: Essential Safety Features

Maintenance Tips for Ensuring Optimal Performance of Disconnect Switches

When it comes to maintaining disconnect switches in electrical systems, ensuring optimal performance hinges on a few critical practices. Regular inspections are essential to identify any signs of wear, corrosion, or mechanical failure. Checking the connections and terminal bolts for tightness can prevent any unexpected disconnections or operational issues. It's advisable to keep the surrounding area clean and free from debris to reduce the risk of overheating or short circuits.

Another vital maintenance tip is to regularly test the functionality of the disconnect switch. This can be done by simulating load conditions to ensure that the switch operates correctly under actual usage scenarios. Additionally, lubrication of moving parts is important to maintain smooth operation, especially in environments that experience extreme temperatures or humidity. Consistently following these maintenance practices will not only enhance the reliability of disconnect switches but also contribute to the overall safety and efficiency of the electrical system.

Home

About Us

Products

Terminal Power Distribution Electric

AC Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

MCB Accessories

Main Switch

RCBO RCCB

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

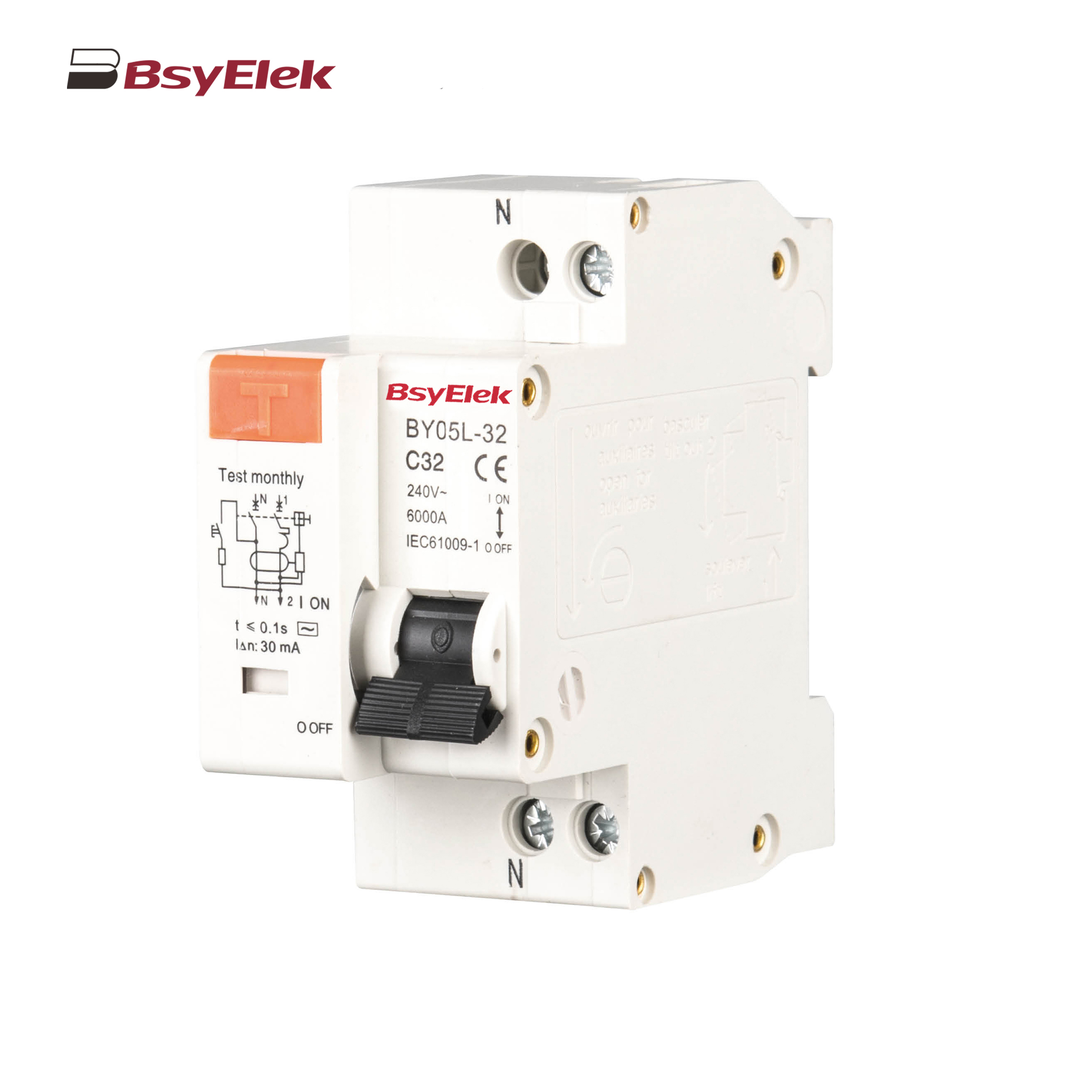

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

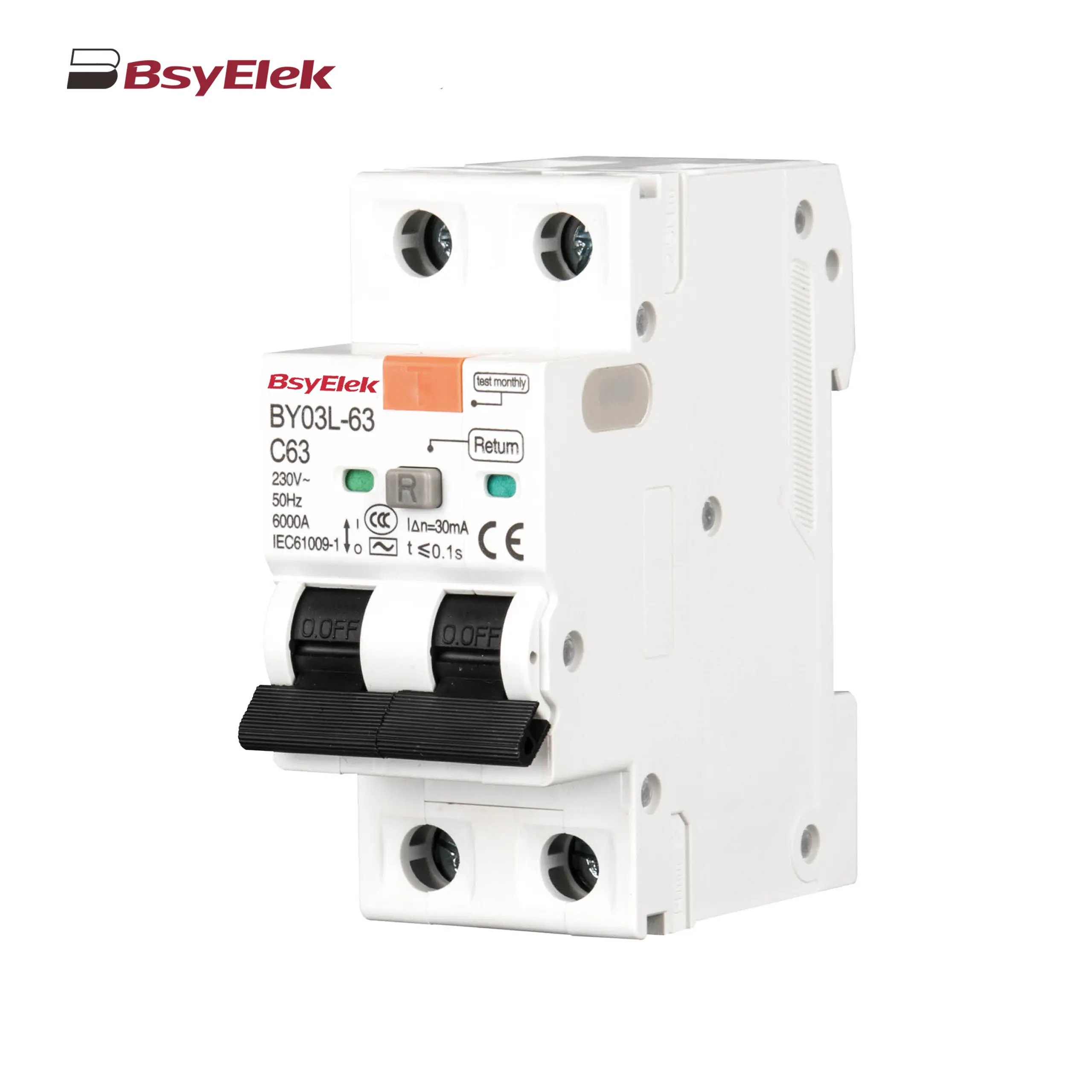

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

Resettable Overvoltage and Undervoltage Protector

AC Contactor

AC Surge Protective Device

Changeover Switch

Photovoltaic System Protection

DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

RCD

DC Surge Protective Device

DC Fuse

PV Isolator Switch

PV Connector

Cable Gland

PV Cable

PV Knife Switch

DC Molded Case Circuit Breaker

Industrial Power Distribution Electric

Distribution Box

Air Conditioning System

Definite Purpose Magnetic Contactor

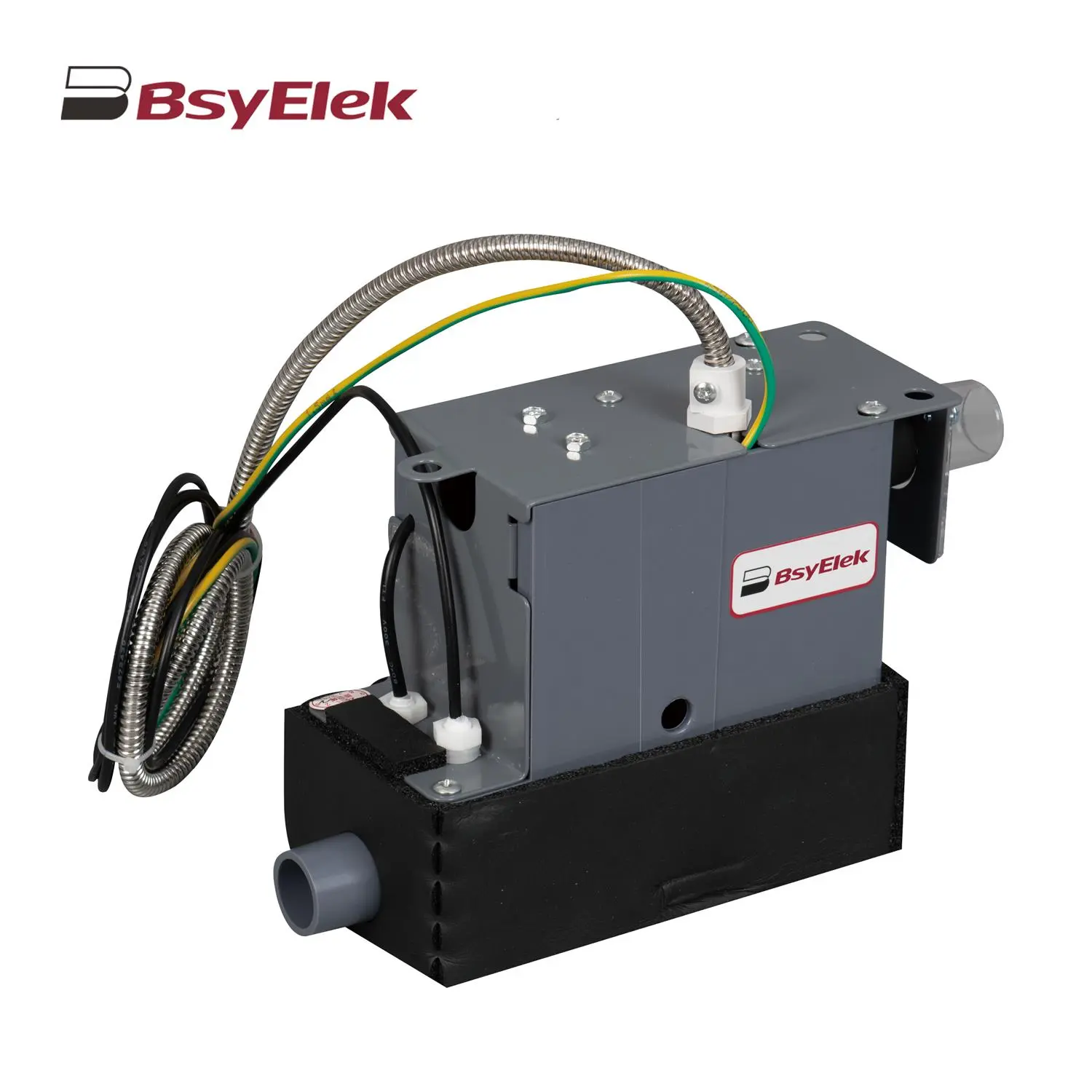

Condensate Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-24B/40B 10M Split Type Drainage Pump

BY-24B/40B 10M Split Type Drainage Pump

BY-100L 2M Drainage Pump of Air Conditioner

BY-100L 2M Drainage Pump of Air Conditioner

BY-360L 6M Large Displacement Drainage Pump

BY-360L 6M Large Displacement Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

News

Top Blog

Company News

Industry Dynamics

What is a miniature circuit breaker (MCB)?

PG Series Waterproof Cable Glands with Washer for Harsh Environments

LWSF-125 125A Manual Changeover Switch ensures reliable power transfer

BYX2 AC contactor series: reliable power control for modern electrical systems

High-performance 1000V DC fuse holder optimizes solar photovoltaic system protection

BY07L-63 Residual Current Circuit Breaker Ensures Global Electrical Safety

BYQ5 ATS Isolation Dual Power Automatic Transfer Switch

BY19G 63A Manual Changeover Switch: Features and Benefits

Support

Blog

Contact Us

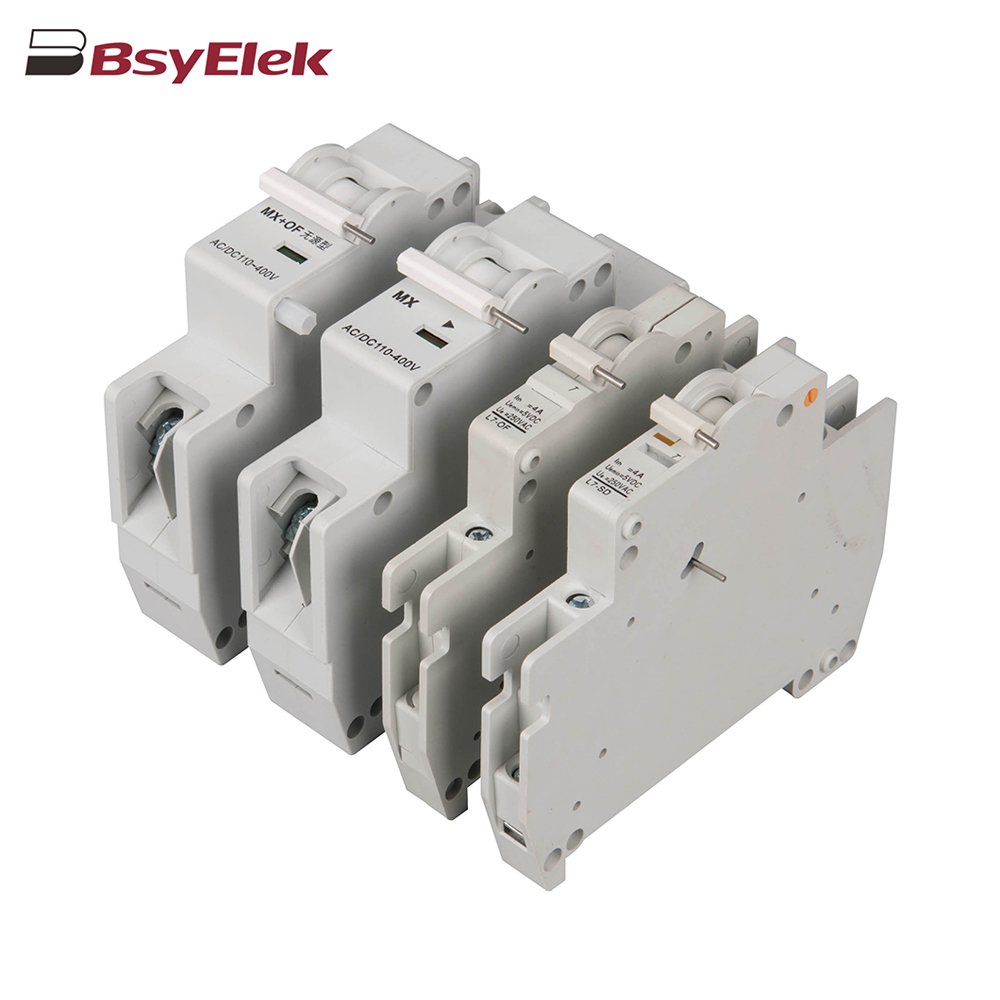

OF SD MX OF MCB Miniature Circuit Breaker Accessories

OF SD MX OF MCB Miniature Circuit Breaker Accessories BYG1-125 Main Switch MCB Isolator Switch

BYG1-125 Main Switch MCB Isolator Switch BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector

BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector

BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector BYX2 6-95A AC Contactor

BYX2 6-95A AC Contactor BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device

BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device

BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device

BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device BY19G 63A Manual Changeover Switch

BY19G 63A Manual Changeover Switch LWSF-125 125A Manual Changeover Switch

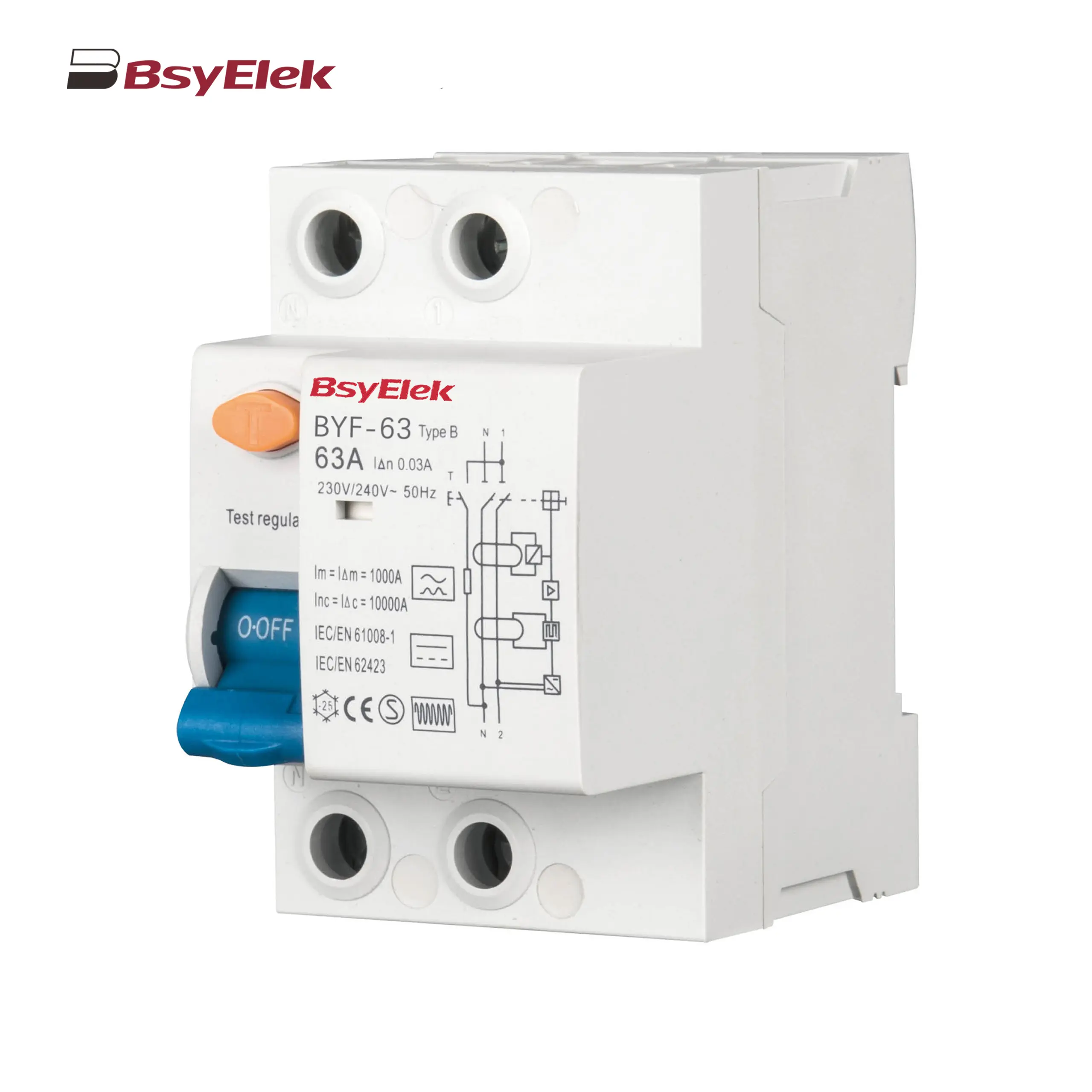

LWSF-125 125A Manual Changeover Switch BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device

BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device

BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device

BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link

BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link

BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link BYPV-ELR2 PV Isolator Switch with Enclosed Version

BYPV-ELR2 PV Isolator Switch with Enclosed Version BYPV-ELR1 PV Isolator Switch with Enclosed Version

BYPV-ELR1 PV Isolator Switch with Enclosed Version BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle

BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle BYPV-NL1 PV Isolator Switch with Lever Handle

BYPV-NL1 PV Isolator Switch with Lever Handle BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle

BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle PV-BY-01 30A/50A 1000V Photovoltaic Connector

PV-BY-01 30A/50A 1000V Photovoltaic Connector PV-BY-02 30A/50A 1500V Photovoltaic Connector

PV-BY-02 30A/50A 1500V Photovoltaic Connector PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector

PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector PV-BY-F01 30A 1500V Diode/Fuse Type Connector

PV-BY-F01 30A 1500V Diode/Fuse Type Connector PV-BY-T 50A 1500V T Type Branch Connector

PV-BY-T 50A 1500V T Type Branch Connector PV-BY-Y 30A 1500V Y Type Branch Connector

PV-BY-Y 30A 1500V Y Type Branch Connector PG Waterproof Cable Gland with Washer

PG Waterproof Cable Gland with Washer Photovoltaic Cable

Photovoltaic Cable HD11N Photovoltaic Knife Switch

HD11N Photovoltaic Knife Switch BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker

BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker

BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker BYM1E MCCB Electronic Type Molded Case Circuit Breaker

BYM1E MCCB Electronic Type Molded Case Circuit Breaker BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker

BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker BYW1 ACB Intelligent Universal Air Circuit Breaker

BYW1 ACB Intelligent Universal Air Circuit Breaker BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch

BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch Stainless Steel Hinge Type Electrical Box

Stainless Steel Hinge Type Electrical Box HA Waterproof Distribution Box

HA Waterproof Distribution Box HT Waterproof Distribution Box

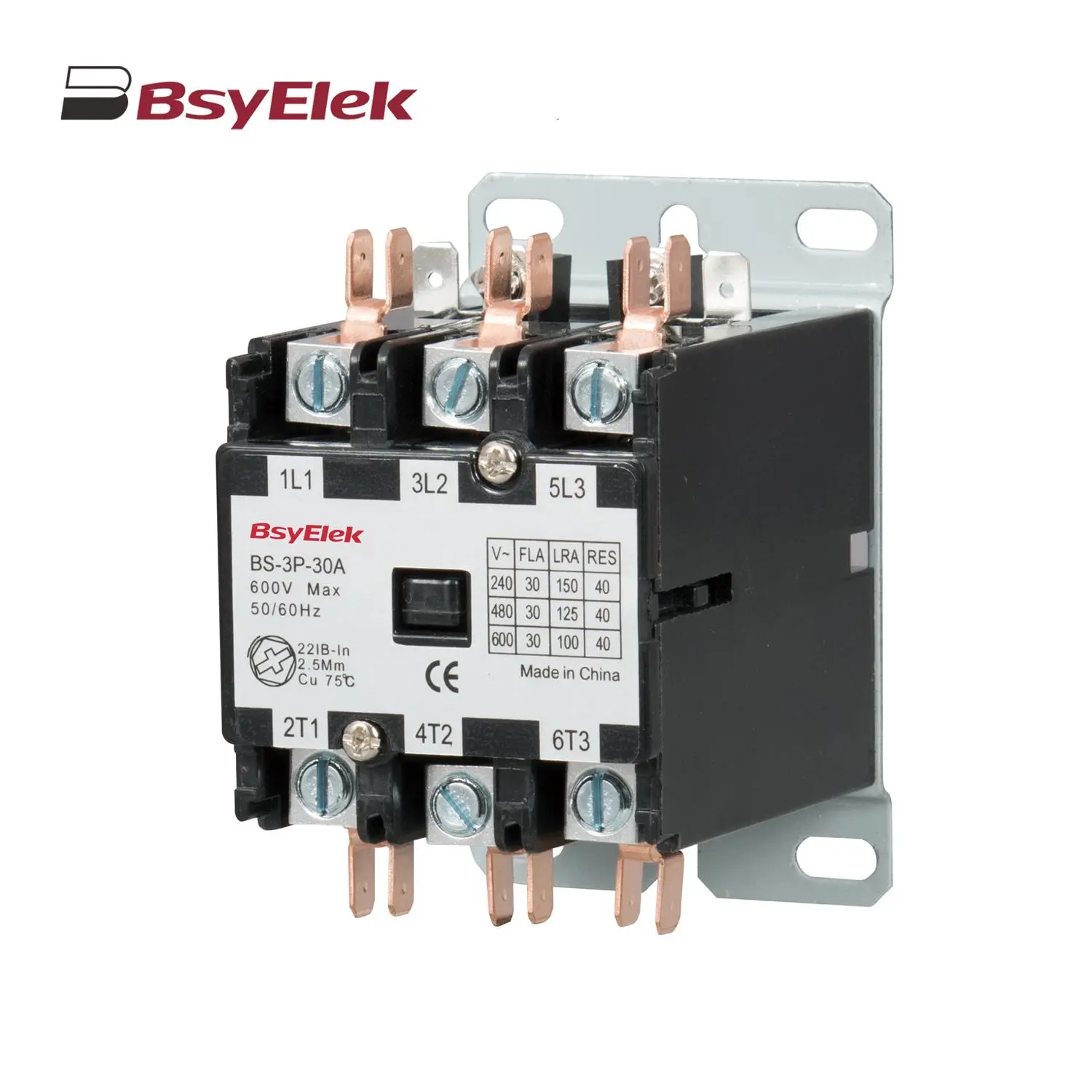

HT Waterproof Distribution Box BS Definite Purpose Magnetic AC Contactor

BS Definite Purpose Magnetic AC Contactor