How to Choose the Right Disconnect Switch for Your Electrical System Needs

In the realm of electrical systems, the choice of a disconnect switch is pivotal to ensuring safety, efficiency, and reliability. Disconnect switches serve as critical components that allow for safe disconnection of equipment from the power source, thereby enabling maintenance and preventing electrical hazards. According to a recent report by Research and Markets, the global market for disconnect switches is projected to reach $7.70 billion by 2026, driven by increasing investments in infrastructure and a growing emphasis on safety standards across industries. As businesses and facilities upgrade their electrical systems, understanding the various types of disconnect switches available—such as fused, non-fused, and safety switches—becomes essential for meeting specific operational and regulatory needs. This blog will guide you through the process of selecting the right disconnect switch, ensuring that your electrical setup remains both compliant and efficient.

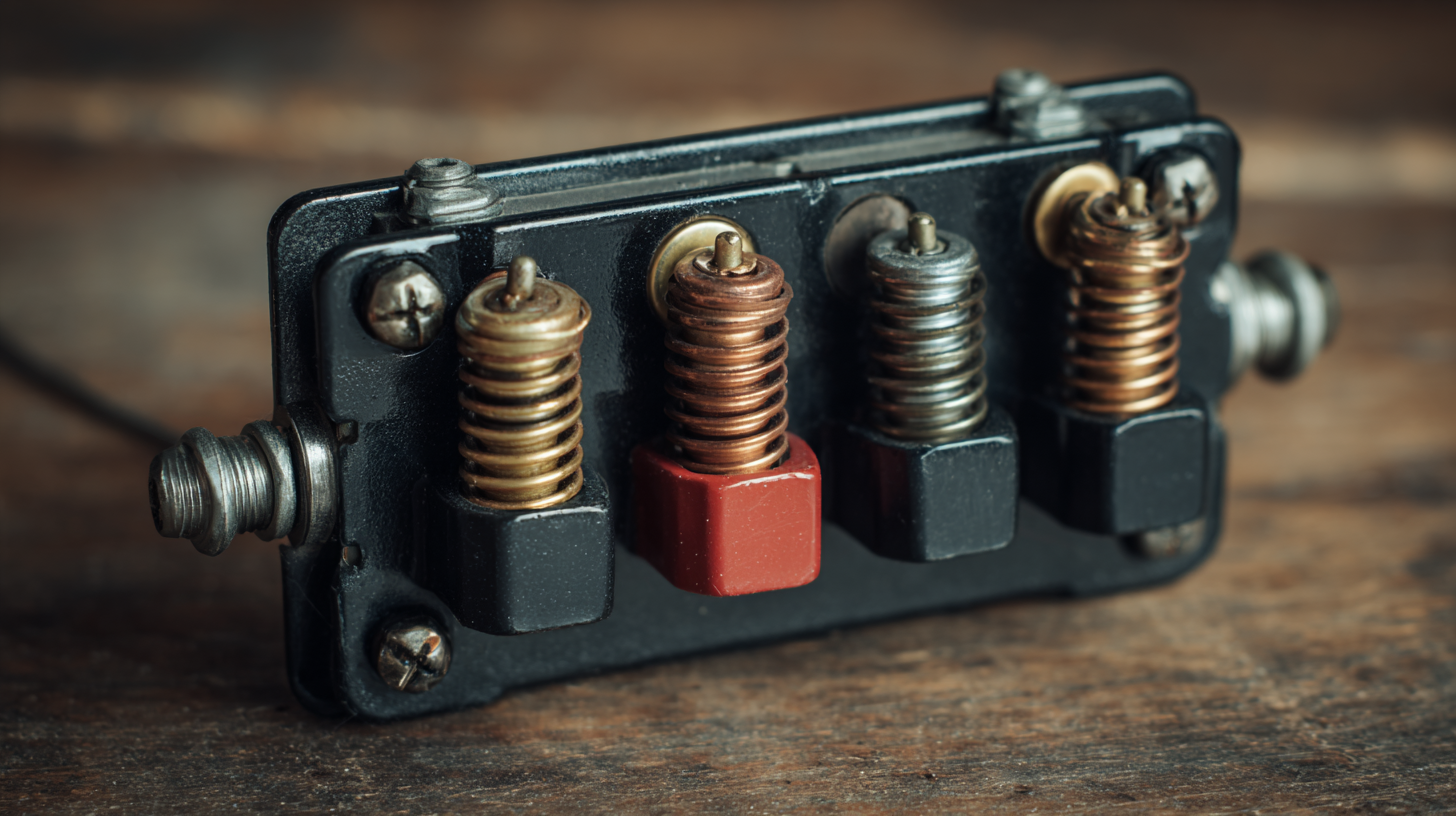

Understanding Disconnect Switches: Types and Applications

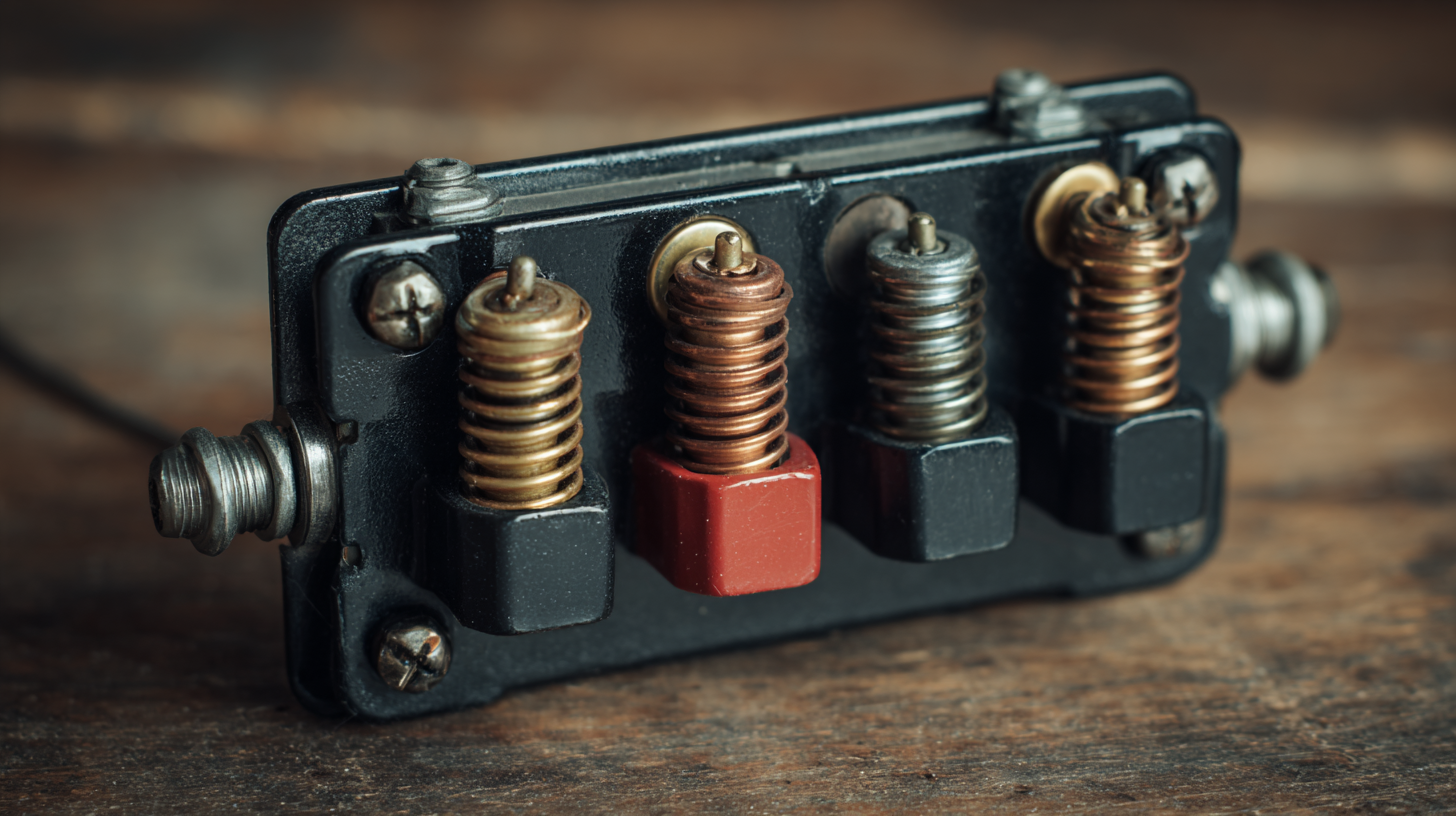

Disconnect switches play a crucial role in ensuring the safety and reliability of electrical systems. They can be classified into two main types: fused and non-fused. Fused disconnect switches offer added protection by incorporating a fuse element that interrupts the circuit during overload conditions. On the other hand, non-fused switches provide a straightforward means of disconnecting power without the additional safety feature of fuses. Understanding these differences can help in making the right choice based on the specific requirements of the electrical installation.

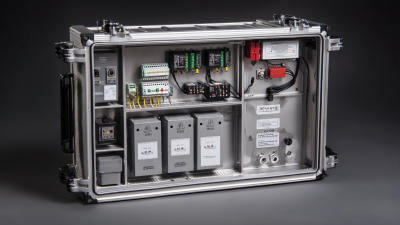

The mounting options for disconnect switches also vary, with common types including panel-mounted and din rail-mounted switches. The choice of mounting often depends on the application and available space. Additionally, the voltage rating is another important consideration, ranging from low voltage configurations up to higher ratings suitable for various industrial applications. As industries increasingly prioritize safety and efficiency, the availability of advanced products like high voltage drives with integrated disconnect solutions demonstrates the market's evolution. This ensures that users can effectively manage their electrical systems while maintaining compliance with safety standards.

How to Choose the Right Disconnect Switch for Your Electrical System Needs

| Type of Disconnect Switch |

Application |

Rated Voltage |

Rated Current |

Safety Features |

| Manual Disconnect Switch |

Industrial Equipment |

600 VAC |

100 A |

Lockable mechanism |

| Automatic Disconnect Switch |

Solar Power Systems |

1000 VDC |

50 A |

Overcurrent protection |

| Combination Disconnect Switch |

Motor Control Centers |

480 VAC |

200 A |

Built-in fuses, Surge protection |

| Load Break Switch |

Power Distribution |

15 kV |

600 A |

Arc extinguishing mechanism |

Key Factors to Consider When Choosing a Disconnect Switch

Choosing the right disconnect switch for your electrical system is crucial for both safety and efficiency. Key factors to consider include the switch's voltage rating and current carrying capacity. According to the NEMA, disconnect switches must be rated to handle the maximum voltage of your system, with considerations for surge conditions that could temporarily exceed these ratings. Accurate voltage and current requirements ensure not only compliance with regulations but also the longevity of your system components.

Choosing the right disconnect switch for your electrical system is crucial for both safety and efficiency. Key factors to consider include the switch's voltage rating and current carrying capacity. According to the NEMA, disconnect switches must be rated to handle the maximum voltage of your system, with considerations for surge conditions that could temporarily exceed these ratings. Accurate voltage and current requirements ensure not only compliance with regulations but also the longevity of your system components.

Another essential factor is the environment in which the switch will operate. A report from the IEEE indicates that up to 30% of electrical failures can be attributed to environmental factors such as humidity, temperature extremes, and exposure to corrosive substances. Selecting a disconnect switch with an appropriate enclosure rating, such as NEMA Type 4 or Type 12, will protect the device and ensure reliable operation under adverse conditions. Taking the time to evaluate these factors can significantly reduce operational risks and enhance the overall durability of your electrical setup.

Best Practices for Sizing Your Disconnect Switch

When sizing a disconnect switch for your electrical system, it's crucial to first determine the maximum load that will be handled. This involves calculating the total current drawn by all connected loads, factoring in any potential future expansions. Understanding the system's voltage and current rating is essential to ensure that the disconnect switch can safely interrupt the flow of electricity without sustaining damage or posing a safety risk.

Another best practice is to select a switch that accommodates the specific environmental conditions of your installation site. For example, if the switch will be exposed to moisture, dust, or extreme temperatures, consider a weatherproof or industrial-grade option to enhance durability and reliability. Additionally, think about the operating mechanism; a manual switch might suffice for smaller applications, while larger systems may benefit from an automatic or remotely operated switch for added convenience and safety. By meticulously considering these factors, you can ensure that you choose the right disconnect switch that meets your system's needs effectively.

Disconnect Switch Sizes for Various Electrical Systems

The Importance of Safety Ratings in Disconnect Switch Selection

When selecting a disconnect switch for your electrical system, safety ratings should be at the forefront of your decision-making process. Disconnect switches are crucial for isolating electrical circuits, especially in high-stakes environments like vehicles and industrial machinery. According to the National Electrical Manufacturers Association (NEMA), safety ratings offer insights into the switch's ability to handle specific voltage and current levels, as well as its performance under various environmental conditions. A switch with a higher safety rating can significantly reduce the risk of electrical fires or hazardous failures.

Furthermore, the latest trends indicate that battery disconnect switches are evolving to meet increasing safety standards and user demands. Reports highlight that more than 80% of new disconnect switches are now designed to be compliant with stringent safety regulations, offering features like overcurrent protection and improved insulation. These advancements not only enhance the reliability of the switch but also provide peace of mind for users who rely on these components in their vehicles or heavy machinery.

Therefore, investing in a high-quality disconnect switch with reputable safety ratings is essential to safeguarding your electrical systems and ensuring their longevity.

Common Brands and Models of Disconnect Switches Explained

When selecting a disconnect switch for your electrical system, it's essential to understand the common brands and models available on the market. Well-known brands like Square D, Siemens, and Eaton offer reliable options tailored to various applications. For instance, Square D's QO series is popular for residential use, providing both safety and efficiency. In contrast, Siemens’ 3AV series is designed for industrial environments, boasting a rugged construction that withstands demanding conditions.

Tips for choosing the right model include assessing the voltage and current ratings that your system requires. Ensure that the disconnect switch is compatible with the rest of your electrical components to prevent system failures. Additionally, consider the installation environment; some models are specifically engineered to resist moisture, dust, or extreme temperatures, making them ideal for outdoor or harsh indoor settings.

Another aspect to keep in mind is the switch’s operational features. Some disconnect switches come with auxiliary contacts, providing additional control options and enhanced safety. By evaluating these characteristics, you can ensure that the disconnect switch you select will meet your specific electrical system needs effectively.

Home

About Us

Products

Terminal Power Distribution Electric

AC Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

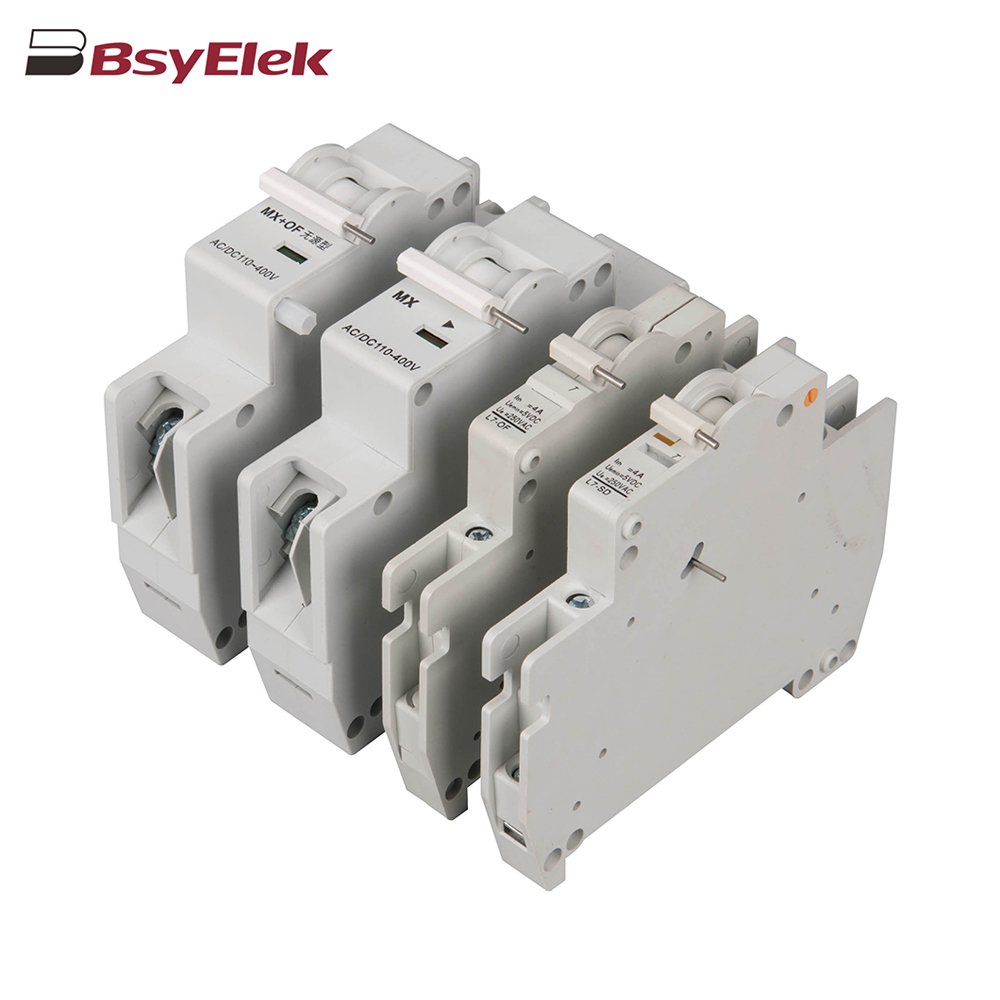

MCB Accessories

Main Switch

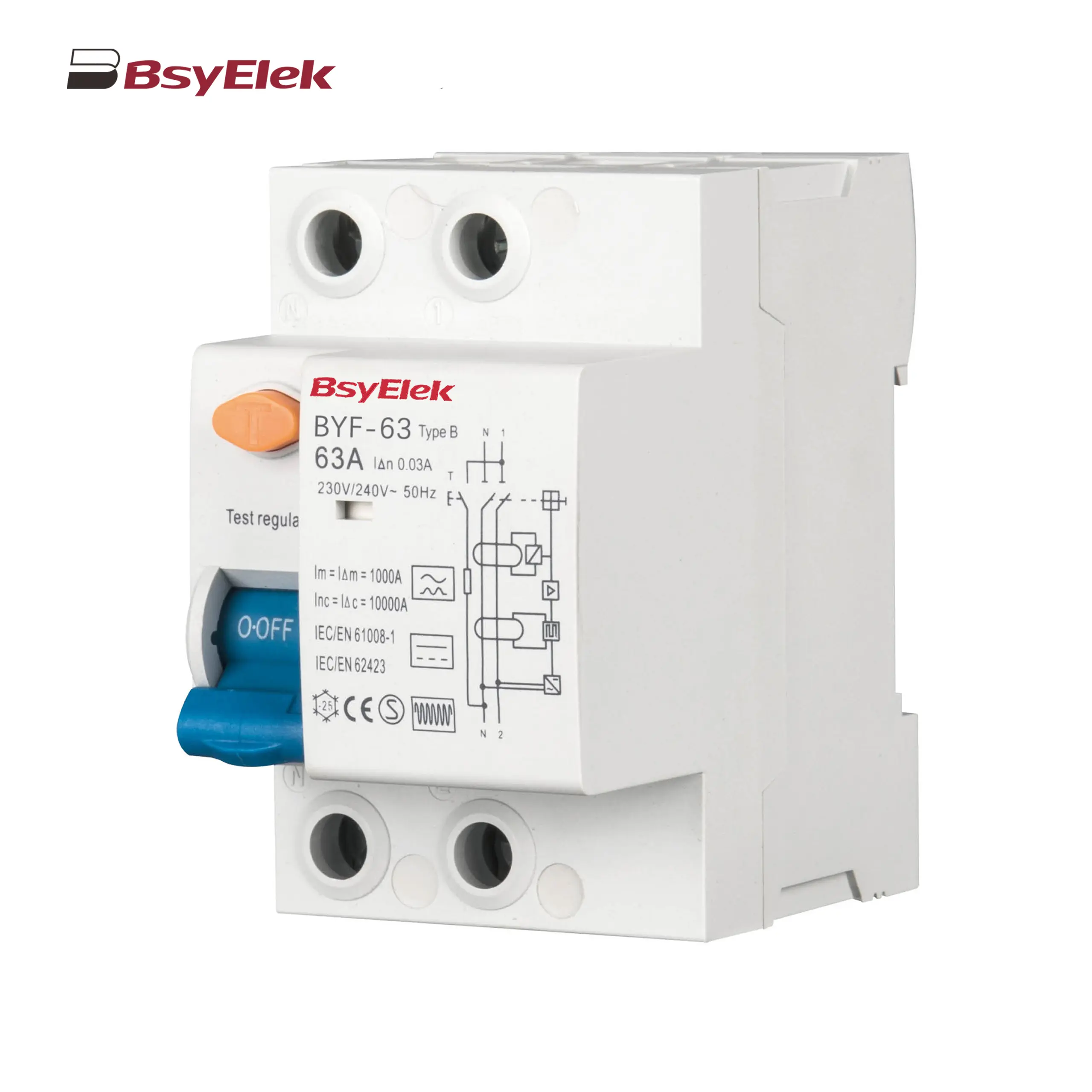

RCBO RCCB

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

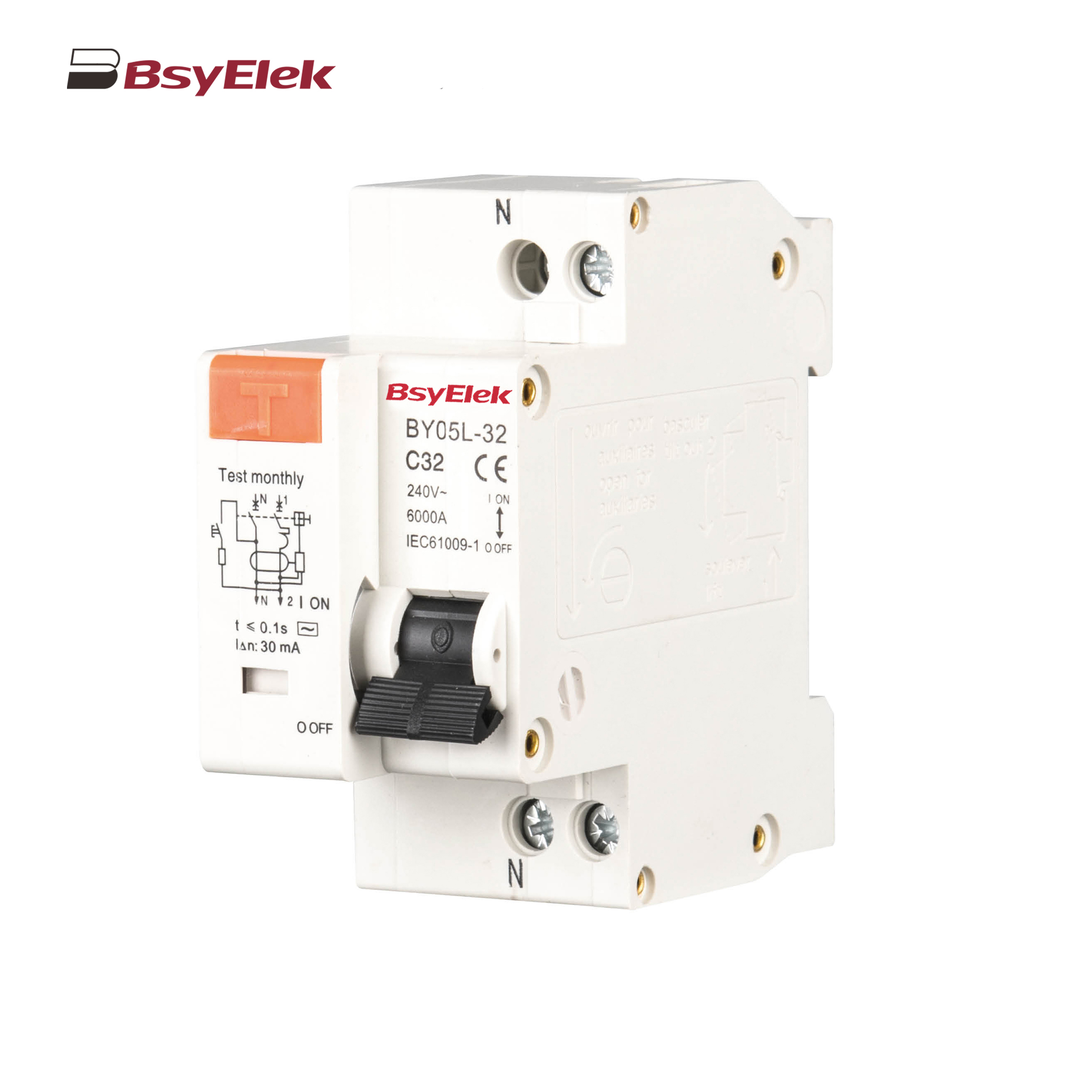

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

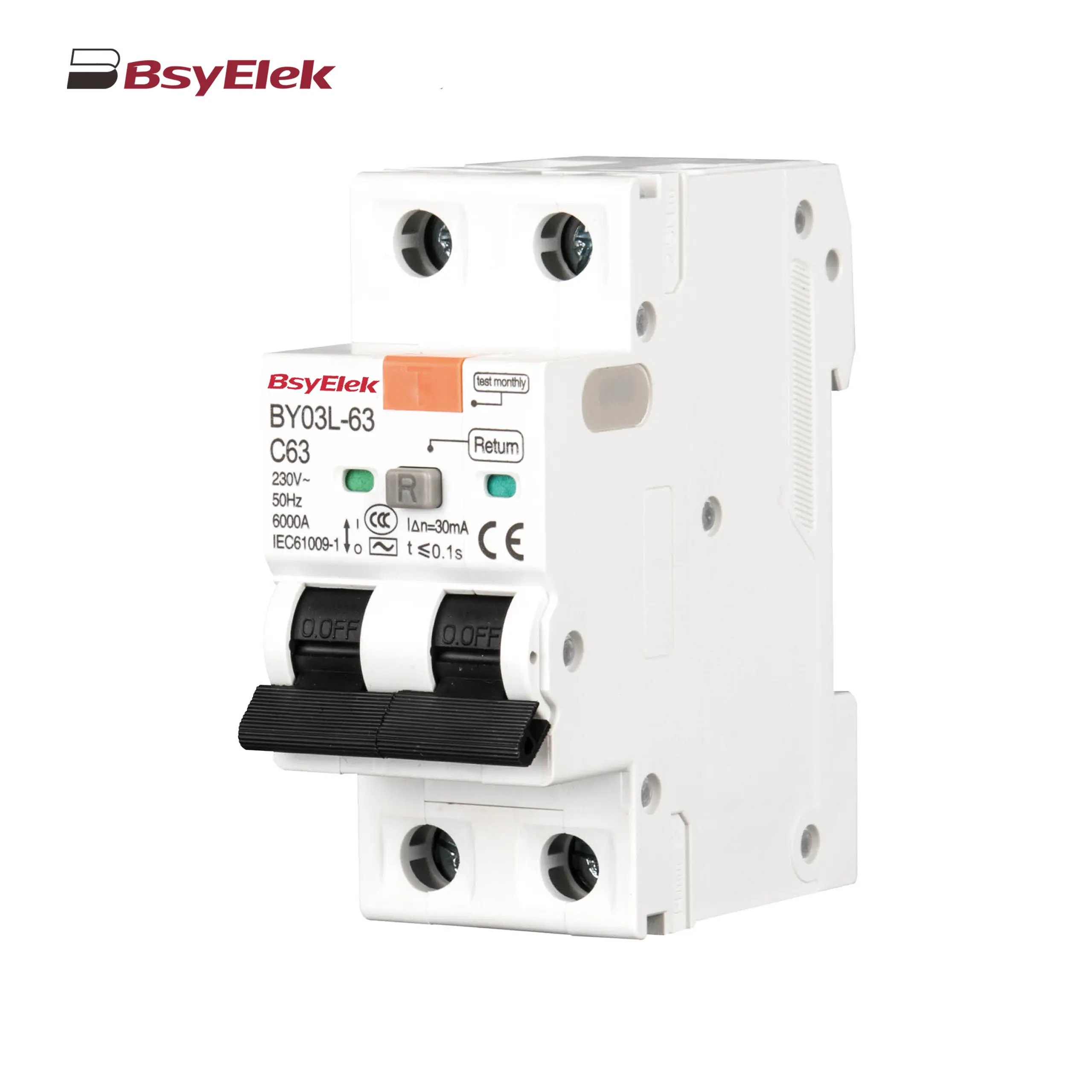

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

Resettable Overvoltage and Undervoltage Protector

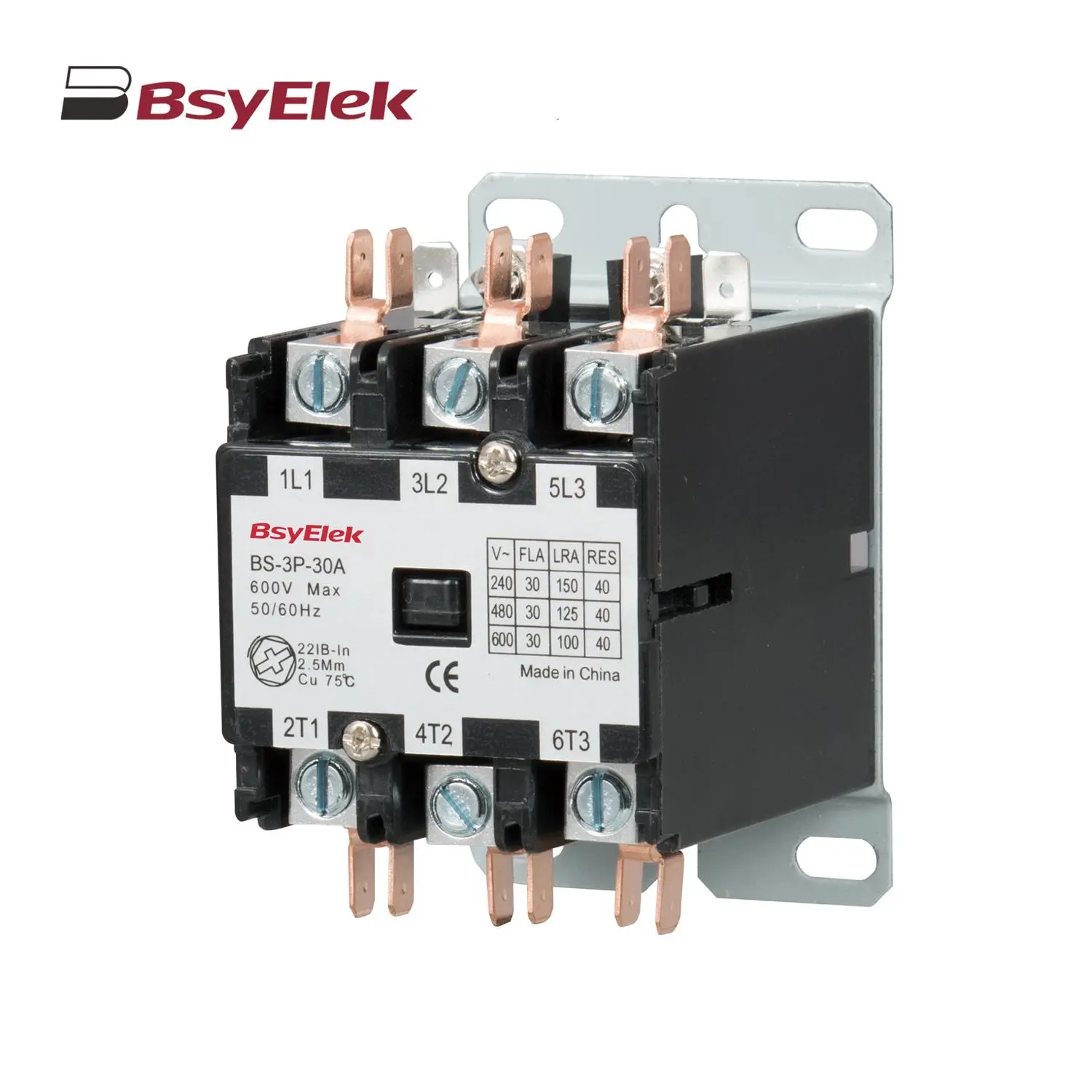

AC Contactor

AC Surge Protective Device

Changeover Switch

Photovoltaic System Protection

DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

RCD

DC Surge Protective Device

DC Fuse

PV Isolator Switch

PV Connector

Cable Gland

PV Cable

PV Knife Switch

DC Molded Case Circuit Breaker

Industrial Power Distribution Electric

Distribution Box

Air Conditioning System

Definite Purpose Magnetic Contactor

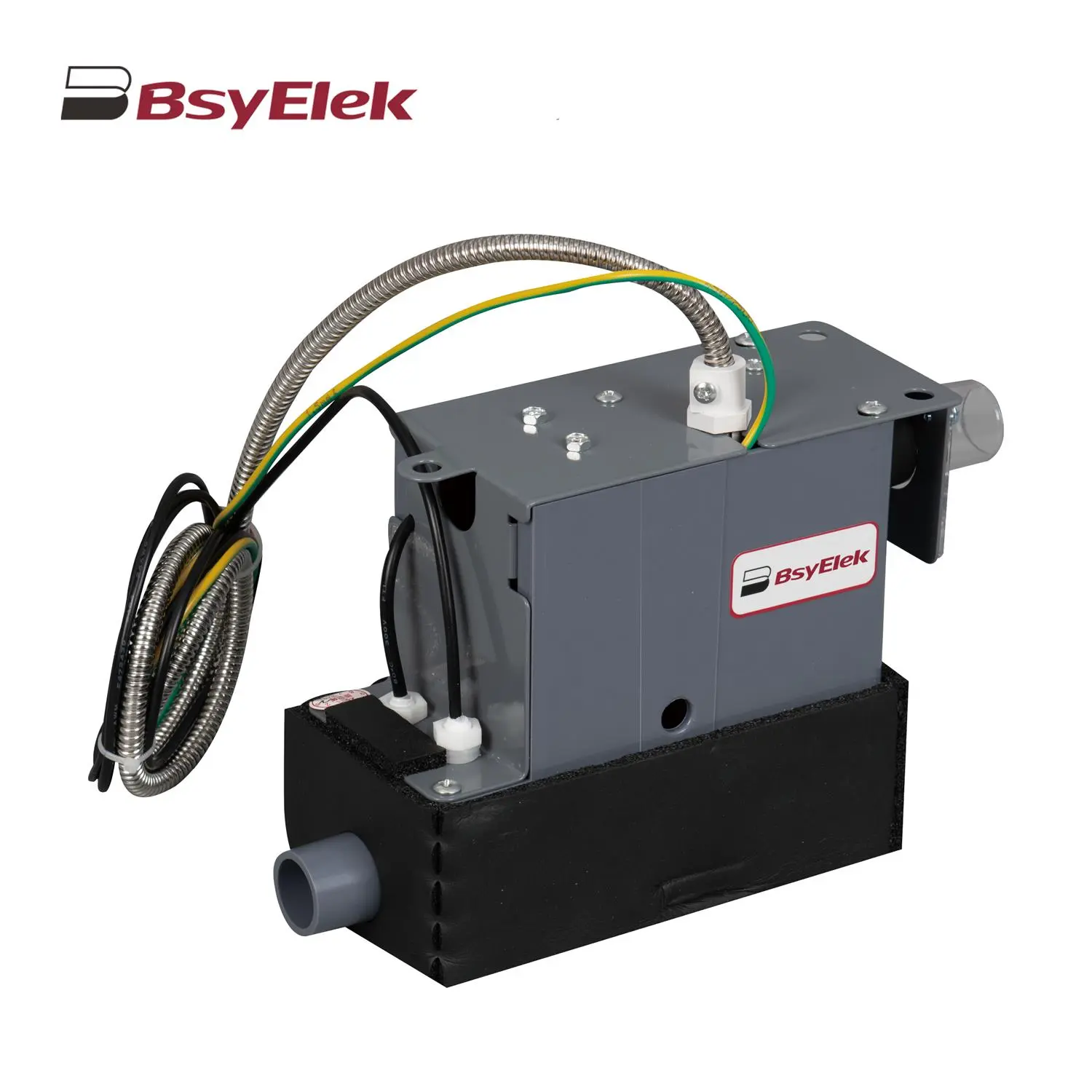

Condensate Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-24B/40B 10M Split Type Drainage Pump

BY-24B/40B 10M Split Type Drainage Pump

BY-100L 2M Drainage Pump of Air Conditioner

BY-100L 2M Drainage Pump of Air Conditioner

BY-360L 6M Large Displacement Drainage Pump

BY-360L 6M Large Displacement Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

News

Top Blog

Company News

Industry Dynamics

What is a miniature circuit breaker (MCB)?

PG Series Waterproof Cable Glands with Washer for Harsh Environments

LWSF-125 125A Manual Changeover Switch ensures reliable power transfer

BYX2 AC contactor series: reliable power control for modern electrical systems

High-performance 1000V DC fuse holder optimizes solar photovoltaic system protection

BY07L-63 Residual Current Circuit Breaker Ensures Global Electrical Safety

BYQ5 ATS Isolation Dual Power Automatic Transfer Switch

BY19G 63A Manual Changeover Switch: Features and Benefits

Support

Blog

Contact Us

OF SD MX OF MCB Miniature Circuit Breaker Accessories

OF SD MX OF MCB Miniature Circuit Breaker Accessories BYG1-125 Main Switch MCB Isolator Switch

BYG1-125 Main Switch MCB Isolator Switch BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector

BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector

BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector BYX2 6-95A AC Contactor

BYX2 6-95A AC Contactor BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device

BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device

BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device

BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device BY19G 63A Manual Changeover Switch

BY19G 63A Manual Changeover Switch LWSF-125 125A Manual Changeover Switch

LWSF-125 125A Manual Changeover Switch BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device

BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device

BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device

BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link

BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link

BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link BYPV-ELR2 PV Isolator Switch with Enclosed Version

BYPV-ELR2 PV Isolator Switch with Enclosed Version BYPV-ELR1 PV Isolator Switch with Enclosed Version

BYPV-ELR1 PV Isolator Switch with Enclosed Version BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle

BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle BYPV-NL1 PV Isolator Switch with Lever Handle

BYPV-NL1 PV Isolator Switch with Lever Handle BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle

BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle PV-BY-01 30A/50A 1000V Photovoltaic Connector

PV-BY-01 30A/50A 1000V Photovoltaic Connector PV-BY-02 30A/50A 1500V Photovoltaic Connector

PV-BY-02 30A/50A 1500V Photovoltaic Connector PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector

PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector PV-BY-F01 30A 1500V Diode/Fuse Type Connector

PV-BY-F01 30A 1500V Diode/Fuse Type Connector PV-BY-T 50A 1500V T Type Branch Connector

PV-BY-T 50A 1500V T Type Branch Connector PV-BY-Y 30A 1500V Y Type Branch Connector

PV-BY-Y 30A 1500V Y Type Branch Connector PG Waterproof Cable Gland with Washer

PG Waterproof Cable Gland with Washer Photovoltaic Cable

Photovoltaic Cable HD11N Photovoltaic Knife Switch

HD11N Photovoltaic Knife Switch BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker

BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker

BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker BYM1E MCCB Electronic Type Molded Case Circuit Breaker

BYM1E MCCB Electronic Type Molded Case Circuit Breaker BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker

BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker BYW1 ACB Intelligent Universal Air Circuit Breaker

BYW1 ACB Intelligent Universal Air Circuit Breaker BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch

BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch Stainless Steel Hinge Type Electrical Box

Stainless Steel Hinge Type Electrical Box HA Waterproof Distribution Box

HA Waterproof Distribution Box HT Waterproof Distribution Box

HT Waterproof Distribution Box BS Definite Purpose Magnetic AC Contactor

BS Definite Purpose Magnetic AC Contactor

Choosing the right disconnect switch for your electrical system is crucial for both safety and efficiency. Key factors to consider include the switch's

Choosing the right disconnect switch for your electrical system is crucial for both safety and efficiency. Key factors to consider include the switch's