Challenges Faced in Meeting Industry Standards for Best Waterproof Distribution Box

In the rapidly evolving electrical industry, the demand for reliable and efficient Waterproof Distribution Boxes has surged, driven by the increasing need for safety and durability in various environments. According to a recent report by XYZ Research, the global market for waterproof distribution boxes is projected to grow at a CAGR of 7.5% from 2022 to 2027, highlighting the critical role these components play in enhancing electrical systems' resilience against harsh conditions. However, manufacturers face significant challenges in meeting the stringent industry standards required to ensure the longevity and performance of these products. Key issues include material selection, design specifications, and rigorous testing protocols to enhance water resistance and overall functionality. As we delve into these challenges, it becomes essential to explore innovative solutions and advancements that can help overcome these obstacles, ultimately leading to superior Waterproof Distribution Boxes that meet and exceed industry expectations.

Overview of Industry Standards for Waterproof Distribution Boxes: Key Regulations and Compliance Requirements

In the quest for high-quality waterproof distribution boxes, industry standards play a crucial role in ensuring products meet safety and performance expectations. Key regulations such as the International Electrotechnical Commission (IEC) 60529 provide guidelines on ingress protection (IP) ratings, which classify the level of dust and water resistance.

According to a 2021 report by Research and Markets, the global waterproof distribution box market is projected to reach USD 1.2 billion by 2026, emphasizing the increasing demand for compliant products.

Compliance with these regulations is not merely a formality but a necessity. Manufacturers must navigate through various compliance requirements, including ISO certification and adherence to regional standards like UL in the United States or CE marking in Europe. A study published by the Technical Association of the Pulp and Paper Industry (TAPPI) indicated that 28% of manufacturers faced substantial challenges in maintaining compliance due to ever-evolving regulations. This situation highlights the importance of understanding and implementing the best practices in manufacturing waterproof distribution boxes that not only meet but exceed these industry standards.

Critical Challenges in Achieving IP Rating Standards for Distribution Boxes in Harsh Environments

Achieving IP rating standards for waterproof distribution boxes is a critical endeavor for manufacturers operating in harsh environments. The Ingress Protection (IP) rating system, which is defined by the International Electrotechnical Commission (IEC), classifies the degree of protection provided against environmental factors like dust and water. For instance, a distribution box rated IP66 can withstand powerful water jets and is totally dust-tight, making it essential for installations in industries such as oil and gas, marine, and construction where exposure to extreme conditions is prevalent. According to a report by Research and Markets, the global waterproof enclosures market is projected to reach $10 billion by 2025, underscoring the industry's growing demand for compliance with these stringent standards.

However, meeting these standards presents numerous challenges. One major hurdle is the testing process itself, which requires specialized equipment and controlled environments to ensure accurate results. Furthermore, manufacturers must navigate the complexities of material selection, ensuring that all components used in the distribution box, from seals to coatings, are capable of maintaining integrity under various stressors. A study published by the Journal of Electrical Engineering noted that nearly 30% of waterproof enclosures fail initial testing due to poor design or inadequate materials, which can significantly delay product launches and increase costs. Therefore, continuous innovation and rigorous testing protocols are essential to overcoming these barriers and meeting the necessary IP ratings.

Impact of Material Selection on Waterproof Performance: Insights from Recent Industry Studies

When considering the waterproof performance of distribution boxes, the selection of materials plays a pivotal role. Recent industry studies indicate that the right choice of materials can enhance the IP rating (Ingress Protection rating) of these boxes significantly. For example, a report from the Waterproofing Industry Association found that boxes made from high-density polyethylene (HDPE) can achieve an IP68 rating, which ensures complete protection against dust and prolonged water immersion. In contrast, using lower-grade materials can limit effectiveness, often resulting in an IP54 rating or lower, exposing components to potential damage.

Moreover, the durability of materials under varying environmental conditions is critical. Research published in the Journal of Materials Engineering notes that materials with UV resistance and corrosion-inhibiting properties tend to maintain their waterproof integrity over time. For instance, polystyrene boxes with added UV stabilizers showed a 40% improvement in long-term waterproofing efficacy compared to standard polystyrene, highlighting the importance of advanced material science in the development of superior waterproof solutions. These insights underscore the necessity for manufacturers to prioritize material selection to ensure compliance with industry standards for optimal performance and longevity.

Testing Methods and Best Practices for Ensuring Durability of Waterproof Distribution Boxes

When it comes to ensuring the durability of waterproof distribution boxes, rigorous testing methods are essential. One common approach is the IP (Ingress Protection) rating system, which assesses how well a box can withstand dust and water ingress. It’s crucial to conduct tests under various environmental conditions to mimic real-world scenarios. This includes exposure to extreme temperatures, humidity, and mechanical impacts, allowing manufacturers to identify potential weaknesses before the boxes enter the market.

Tips: Always document the testing process thoroughly. This not only helps in understanding the performance of the distribution boxes but also provides valuable data for future improvements. Additionally, consider employing third-party testing services to enhance credibility, as independent assessments can provide an unbiased review of your product's durability.

Another best practice involves the use of advanced materials that enhance water resistance without compromising strength. Conducting long-term exposure tests can also help determine how materials react over time when subjected to harsh conditions. Regularly updating design and material choices based on testing results ensures that distribution boxes remain reliable and effective.

Tips: Collaborate with engineers to explore innovative designs that promote drainage and airflow within the box, which can prevent water buildup and reduce corrosion risks. Engaging with end-users during the testing phase can provide insights into practical issues they may encounter, ultimately leading to more robust solutions.

The Role of Innovation in Overcoming Technical Barriers to Meeting Industry Standards

Innovation plays a critical role in overcoming the technical barriers faced by manufacturers of waterproof distribution boxes. With the global waterproofing market projected to reach $23 billion by 2026, as noted by a recent MarketsandMarkets report, the push for more sophisticated and compliant designs is imperative. Industry standards such as the IP68 rating, which ensures complete protection against dust and prolonged water immersion, demand not only robust material selection but also advanced engineering techniques. As firms adopt innovative materials like polycarbonate and advanced sealing technologies, they can enhance both durability and compliance with rigorous standards.

Furthermore, the integration of smart technology into waterproof distribution boxes has positioned companies to better meet industry expectations. According to a report from Grand View Research, the smart distribution box segment is anticipated to grow at a CAGR of 12.2% from 2021 to 2028. This growth highlights the necessity of addressing technical hurdles, such as ensuring connectivity while maintaining water resistance. By leveraging IoT capabilities, manufacturers can create solutions that not only meet waterproof standards but also offer real-time data monitoring, ultimately leading to a safer and more efficient distribution system.

Home

About Us

Products

Terminal Power Distribution Electric

AC Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

MCB Accessories

Main Switch

RCBO RCCB

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

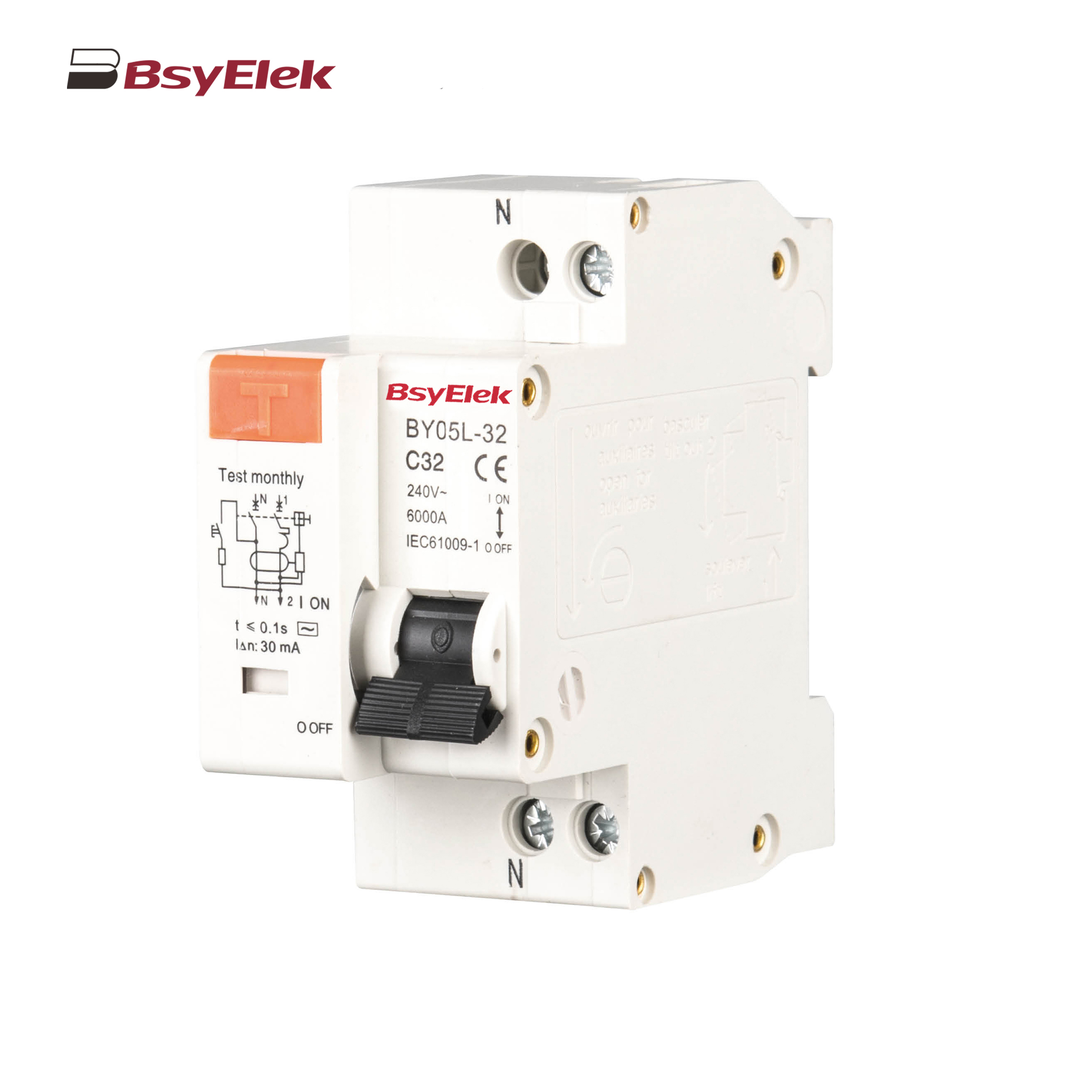

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

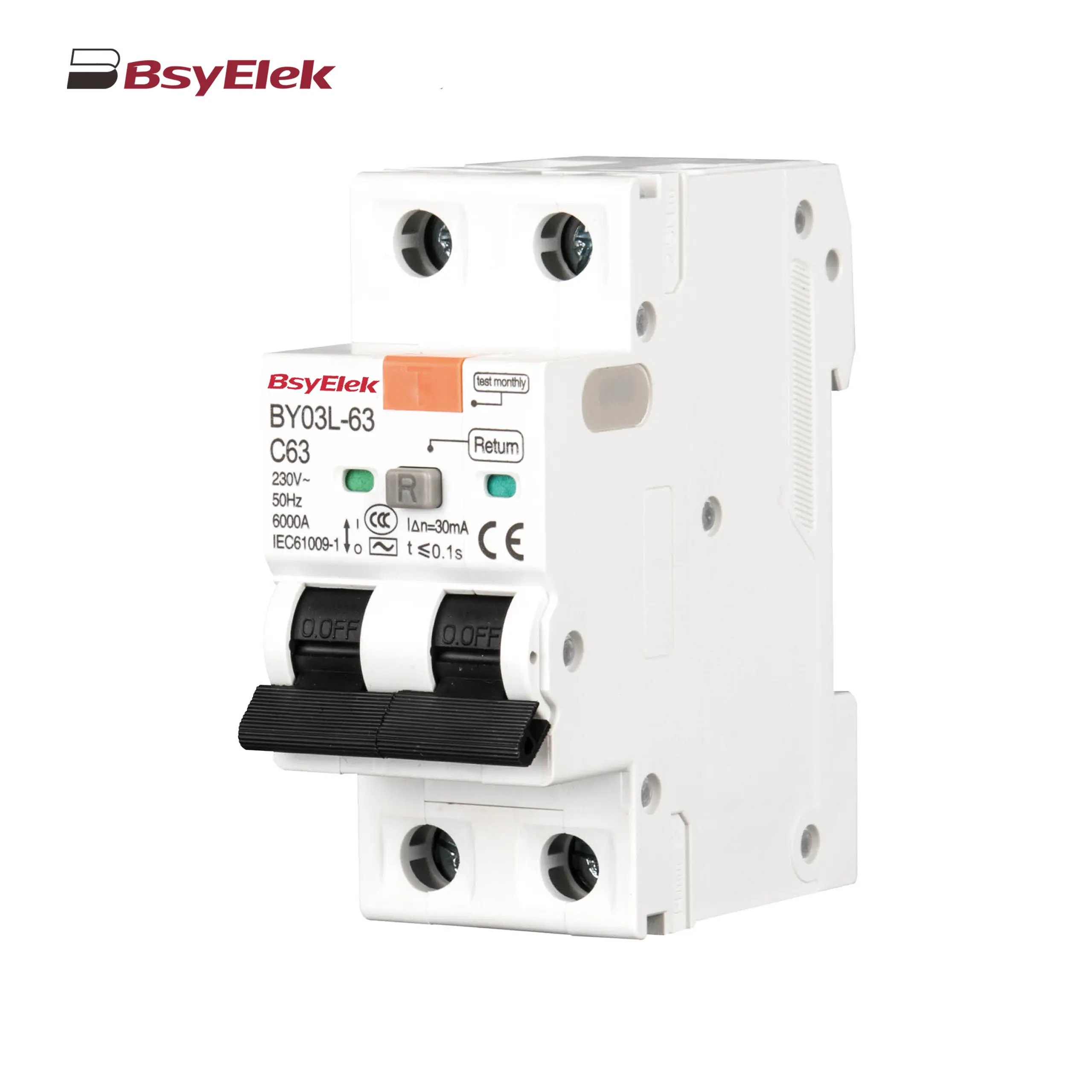

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

Resettable Overvoltage and Undervoltage Protector

AC Contactor

AC Surge Protective Device

Changeover Switch

Photovoltaic System Protection

DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

RCD

DC Surge Protective Device

DC Fuse

PV Isolator Switch

PV Connector

Cable Gland

PV Cable

PV Knife Switch

DC Molded Case Circuit Breaker

Industrial Power Distribution Electric

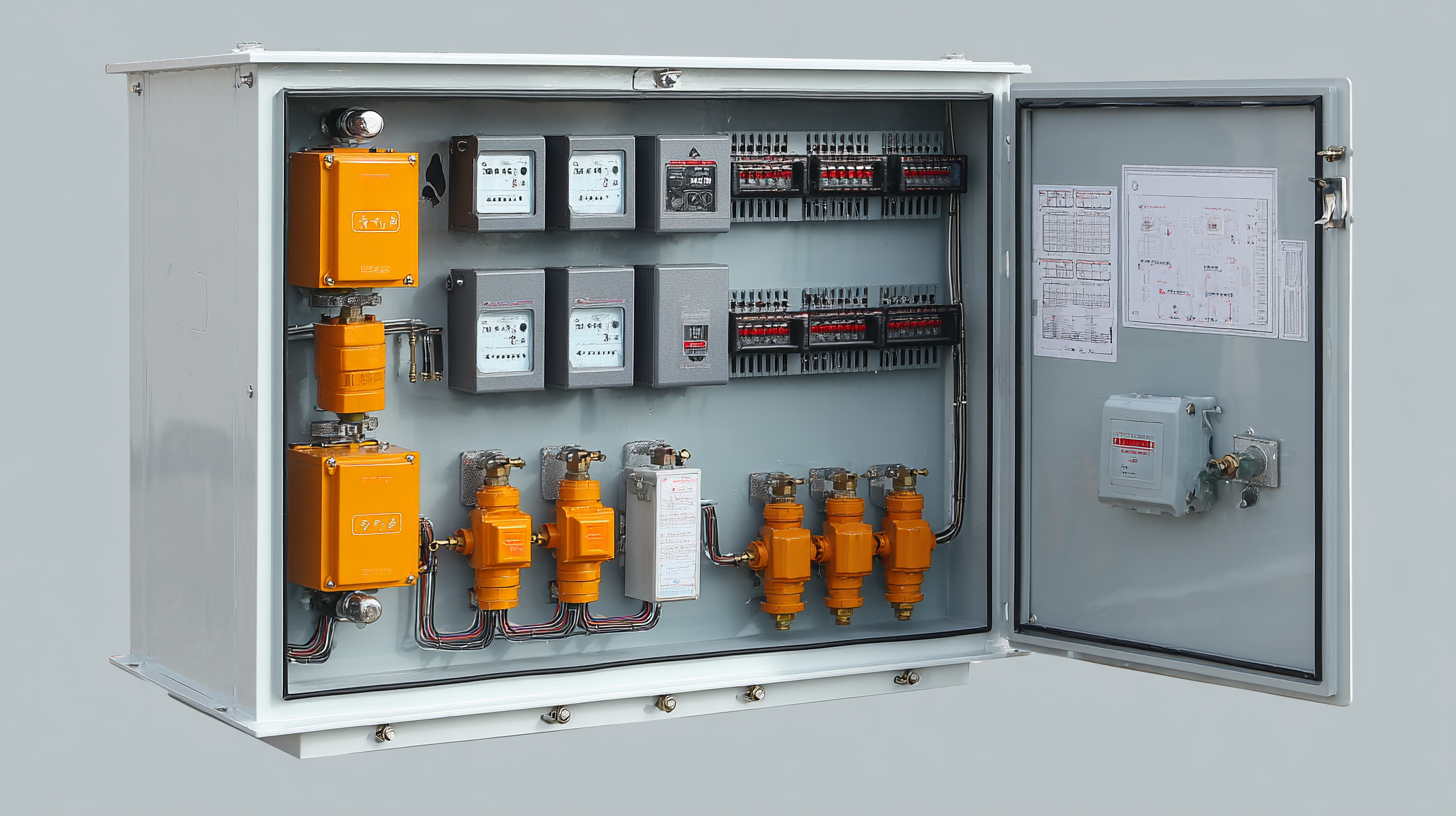

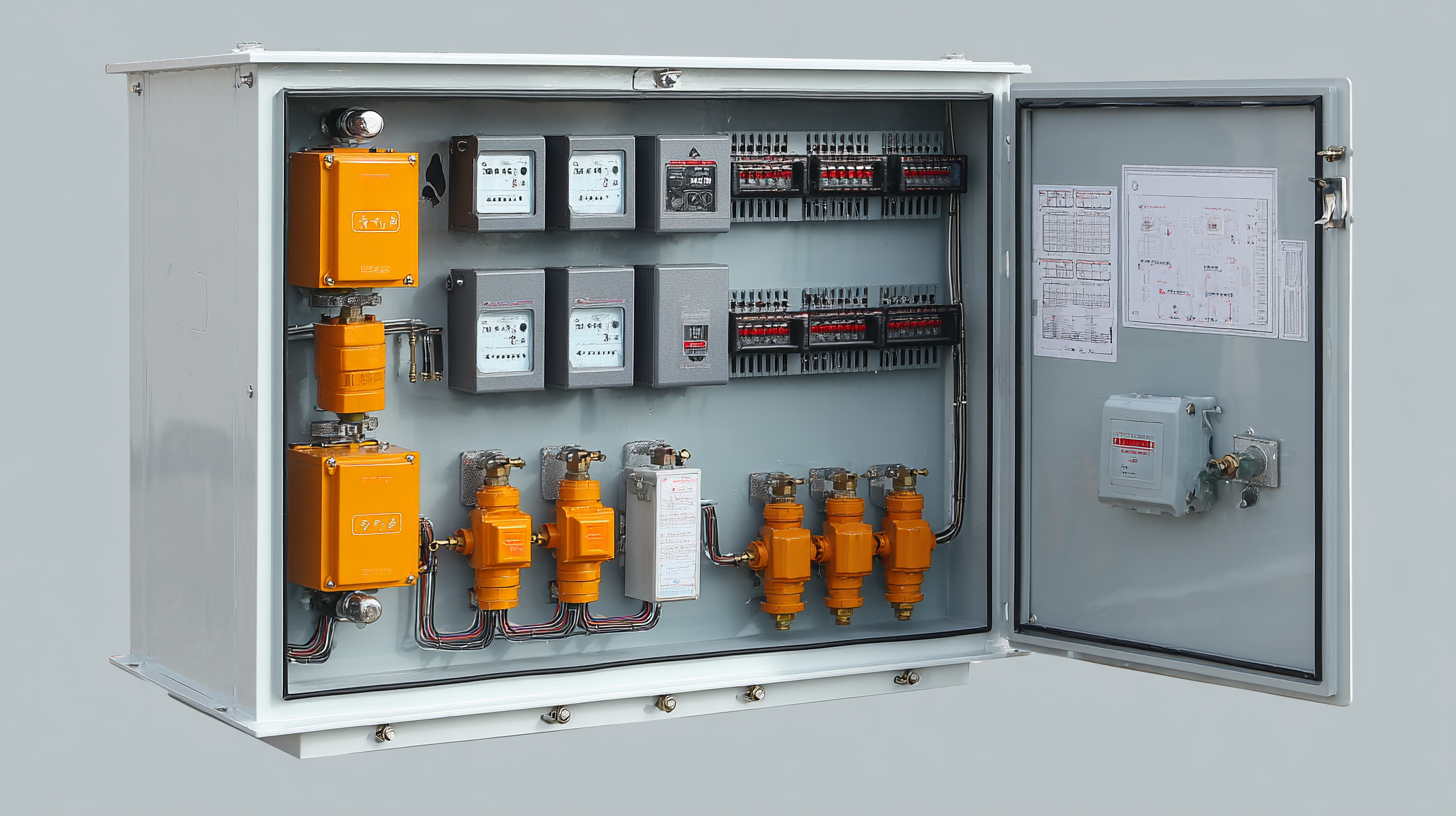

Distribution Box

Air Conditioning System

Definite Purpose Magnetic Contactor

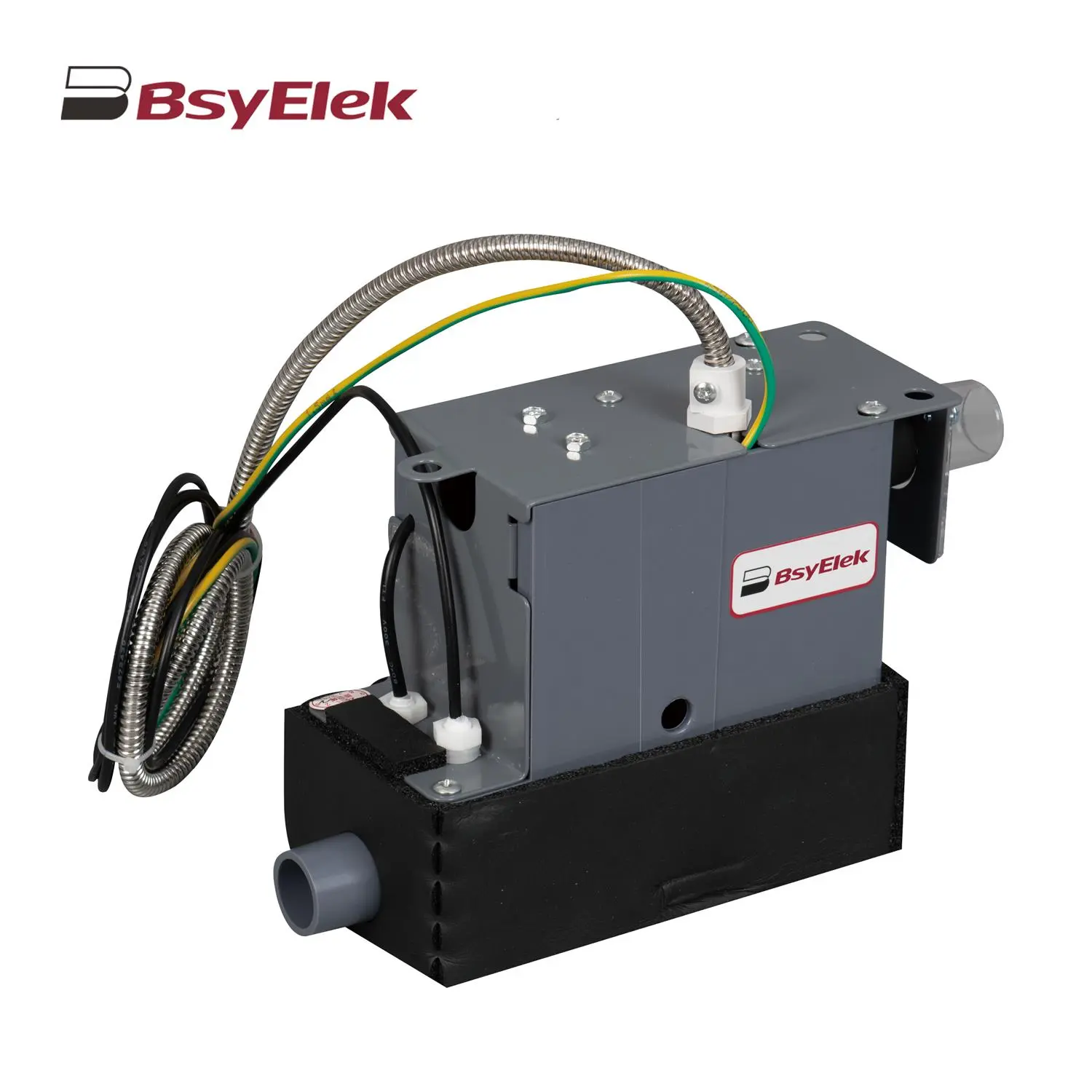

Condensate Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-24B/40B 10M Split Type Drainage Pump

BY-24B/40B 10M Split Type Drainage Pump

BY-100L 2M Drainage Pump of Air Conditioner

BY-100L 2M Drainage Pump of Air Conditioner

BY-360L 6M Large Displacement Drainage Pump

BY-360L 6M Large Displacement Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

News

Top Blog

Company News

Industry Dynamics

What is a miniature circuit breaker (MCB)?

PG Series Waterproof Cable Glands with Washer for Harsh Environments

LWSF-125 125A Manual Changeover Switch ensures reliable power transfer

BYX2 AC contactor series: reliable power control for modern electrical systems

High-performance 1000V DC fuse holder optimizes solar photovoltaic system protection

BY07L-63 Residual Current Circuit Breaker Ensures Global Electrical Safety

BYQ5 ATS Isolation Dual Power Automatic Transfer Switch

BY19G 63A Manual Changeover Switch: Features and Benefits

Support

Blog

Contact Us

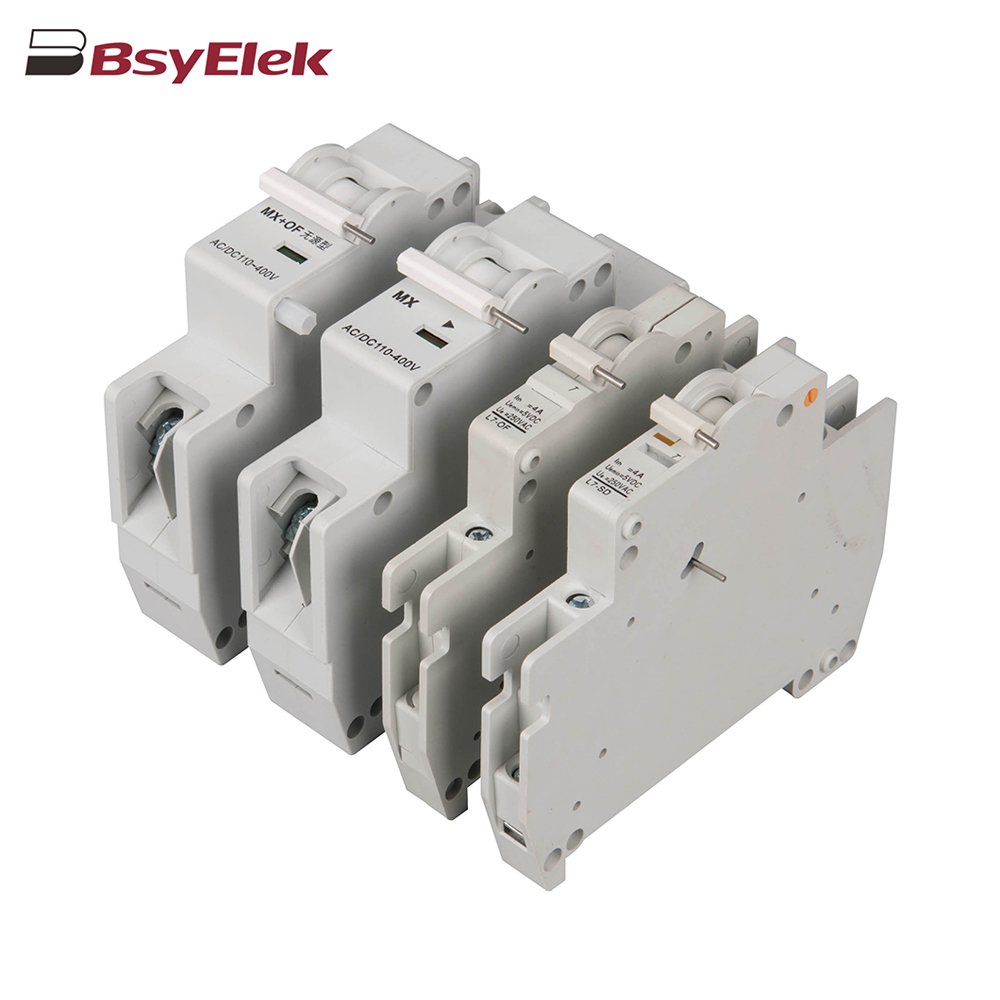

OF SD MX OF MCB Miniature Circuit Breaker Accessories

OF SD MX OF MCB Miniature Circuit Breaker Accessories BYG1-125 Main Switch MCB Isolator Switch

BYG1-125 Main Switch MCB Isolator Switch BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector

BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector

BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector BYX2 6-95A AC Contactor

BYX2 6-95A AC Contactor BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device

BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device

BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device

BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device BY19G 63A Manual Changeover Switch

BY19G 63A Manual Changeover Switch LWSF-125 125A Manual Changeover Switch

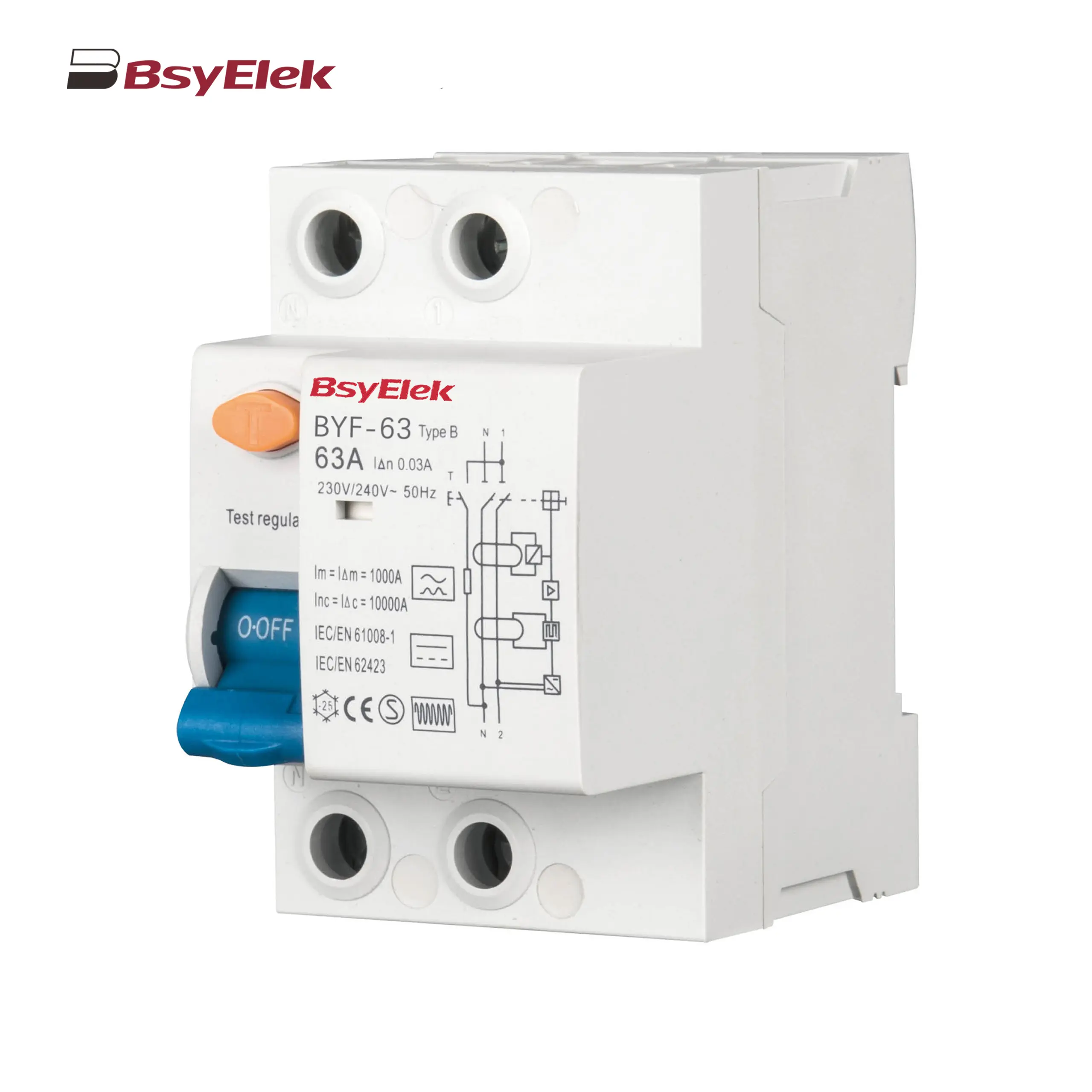

LWSF-125 125A Manual Changeover Switch BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device

BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device

BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device

BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link

BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link

BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link BYPV-ELR2 PV Isolator Switch with Enclosed Version

BYPV-ELR2 PV Isolator Switch with Enclosed Version BYPV-ELR1 PV Isolator Switch with Enclosed Version

BYPV-ELR1 PV Isolator Switch with Enclosed Version BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle

BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle BYPV-NL1 PV Isolator Switch with Lever Handle

BYPV-NL1 PV Isolator Switch with Lever Handle BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle

BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle PV-BY-01 30A/50A 1000V Photovoltaic Connector

PV-BY-01 30A/50A 1000V Photovoltaic Connector PV-BY-02 30A/50A 1500V Photovoltaic Connector

PV-BY-02 30A/50A 1500V Photovoltaic Connector PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector

PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector PV-BY-F01 30A 1500V Diode/Fuse Type Connector

PV-BY-F01 30A 1500V Diode/Fuse Type Connector PV-BY-T 50A 1500V T Type Branch Connector

PV-BY-T 50A 1500V T Type Branch Connector PV-BY-Y 30A 1500V Y Type Branch Connector

PV-BY-Y 30A 1500V Y Type Branch Connector PG Waterproof Cable Gland with Washer

PG Waterproof Cable Gland with Washer Photovoltaic Cable

Photovoltaic Cable HD11N Photovoltaic Knife Switch

HD11N Photovoltaic Knife Switch BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker

BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker

BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker BYM1E MCCB Electronic Type Molded Case Circuit Breaker

BYM1E MCCB Electronic Type Molded Case Circuit Breaker BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker

BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker BYW1 ACB Intelligent Universal Air Circuit Breaker

BYW1 ACB Intelligent Universal Air Circuit Breaker BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch

BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch Stainless Steel Hinge Type Electrical Box

Stainless Steel Hinge Type Electrical Box HA Waterproof Distribution Box

HA Waterproof Distribution Box HT Waterproof Distribution Box

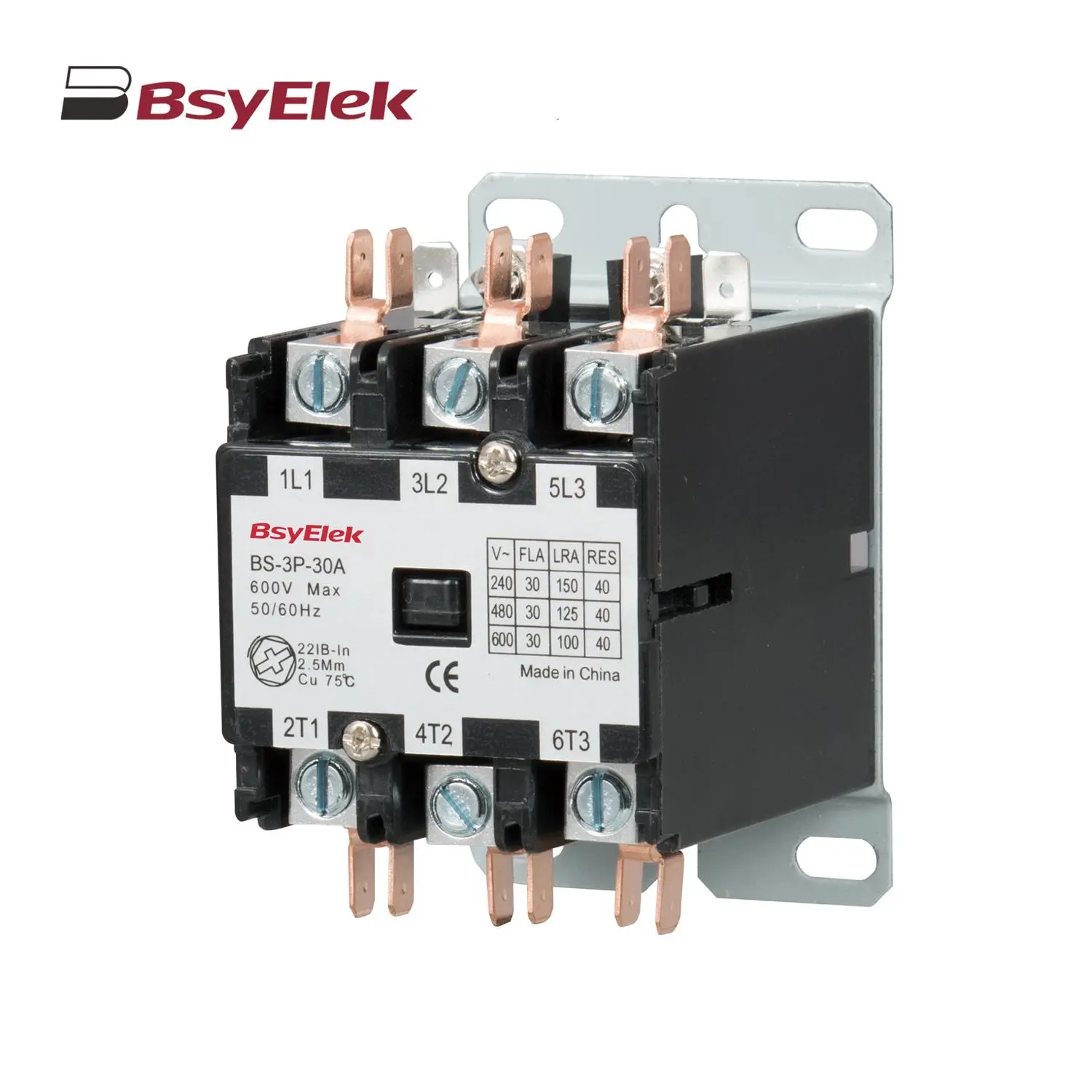

HT Waterproof Distribution Box BS Definite Purpose Magnetic AC Contactor

BS Definite Purpose Magnetic AC Contactor