The Best 10 Magnetic Contactors for Reliable Electrical Control

In the realm of electrical control, magnetic contactors play a pivotal role, ensuring reliable operation across various applications. According to Dr. Emily Carter, a leading expert in electrical engineering, "Choosing the right magnetic contactor can significantly impact the efficiency and safety of an electrical system." This statement underscores the importance of selecting high-quality components for optimal performance.

Magnetic contactors are electromagnetic switches designed to control high-voltage circuits with low-voltage signals, providing a critical interface in modern electrical systems. With advancements in technology and an increasing demand for automation, selecting the best magnetic contactor is essential for both industrial and residential projects. In this context, understanding the features and specifications of the available options will guide users in making informed choices, ultimately enhancing the reliability and efficiency of their electrical setups.

As we delve into the top 10 magnetic contactors on the market, we will explore their key characteristics, benefits, and applications. By highlighting these essential components, we aim to equip you with the knowledge needed to navigate the complexities of electrical control systems, ensuring that your projects run smoothly and safely with the right magnetic contactor in place.

Understanding Magnetic Contactors and Their Importance in Electrical Systems

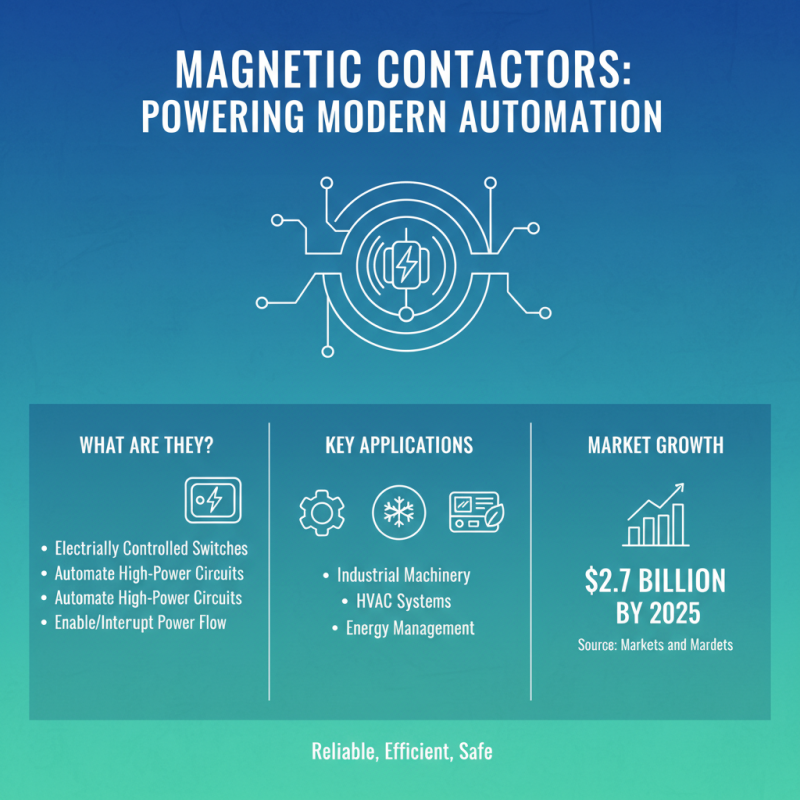

Magnetic contactors play a crucial role in modern electrical systems, acting as essential components that facilitate the control of high-power electrical circuits. These devices serve as electrically controlled switches, allowing for the automation of machinery by enabling or interrupting power flow without the need for direct human intervention. This is vital in applications ranging from industrial machinery to HVAC systems, where reliable performance is necessary to ensure operational efficiency and safety. According to a report by Markets and Markets, the magnetic contactor market is projected to reach $2.7 billion by 2025, reflecting its growing significance in energy management and automation.

Understanding the functionality of magnetic contactors is key to appreciating their importance in electrical control. They consist of an electromechanical coil that, when energized, creates a magnetic field, drawing the contactor's contacts together to complete the circuit. The ability to handle substantial loads means that magnetic contactors can operate multiple electrical devices simultaneously, contributing to an efficient electrical distribution system. The International Electrotechnical Commission (IEC) outlines rigorous standards for these devices, highlighting their reliability and the necessity for proper selection to avoid issues such as overheating or contact welding. Ensuring the right specifications can significantly enhance system performance and longevity, making magnetic contactors a vital component in any electrical infrastructure.

Key Features to Consider When Selecting a Magnetic Contactor

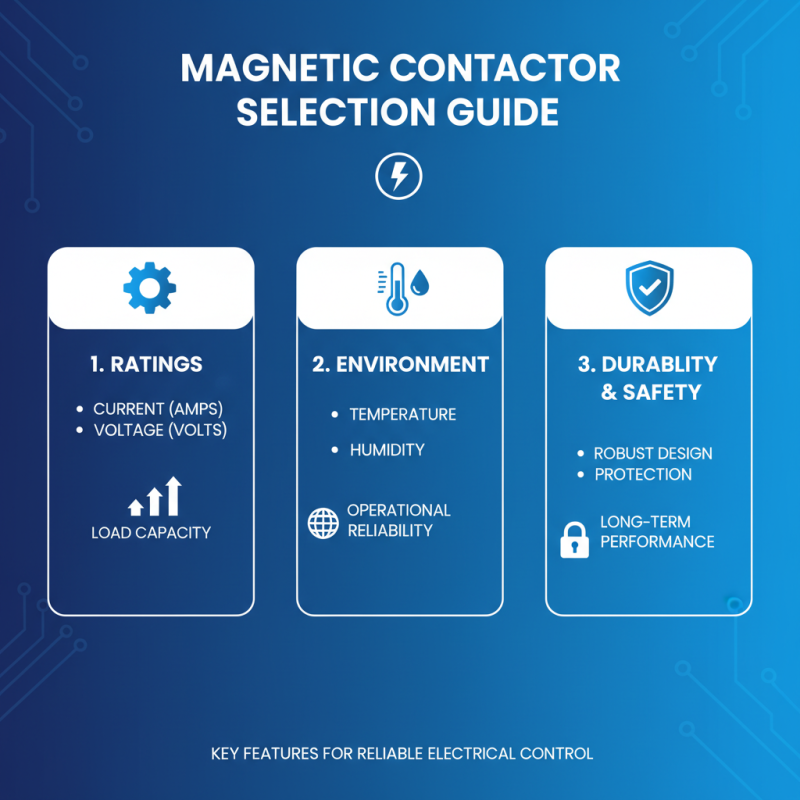

When selecting a magnetic contactor for reliable electrical control, there are several key features to consider that can greatly influence performance and safety. One of the critical aspects is the contactor's current and voltage ratings. It is essential to choose a contactor that can handle the specific load requirements of the application without overheating or failing. Additionally, understanding the operational environment, such as temperature and humidity levels, can help in selecting a product that is both durable and reliable under the given conditions.

Another important factor to evaluate is the contact arrangement, including the number of poles needed for the application. Single-pole, double-pole, or three-pole contactors serve different purposes, so ensuring the correct number of poles aligns with your operational requirements is vital. Furthermore, consider the contactor's coil voltage compatibility with your control circuit—this aspect can prevent potential malfunctions and ensure smooth operation. Lastly, the ease of installation and maintenance is crucial; look for features that facilitate quick wiring and adjustments, as well as robust construction to withstand frequent cycling and long-term use.

Top 10 Magnetic Contactors: Overview of Performance and Reliability

When it comes to ensuring reliable electrical control in various applications,

magnetic contactors play a vital role.

Their primary function is to switch electrical circuits on and off, allowing for efficient management of

power distribution. Performance is a key factor when evaluating magnetic contactors; it includes

aspects such as response time, ease of operation, and overall durability

under continuous use. A well-performing magnetic contactor effectively minimizes the risk of

electrical faults, contributing to a safer working environment.

Reliability is equally crucial, as these devices often operate in demanding conditions. The best

magnetic contactors are designed to withstand fluctuations in voltage and intense operational cycles without

compromising their functionality. Manufacturers often utilize high-quality materials and

advanced engineering techniques to enhance the longevity and stability of these devices. Therefore, selecting

a magnetic contactor that combines robust performance with reliability ensures that electrical systems operate

efficiently, reducing maintenance costs and downtime.

Comparative Analysis of Leading Brands in Magnetic Contactors

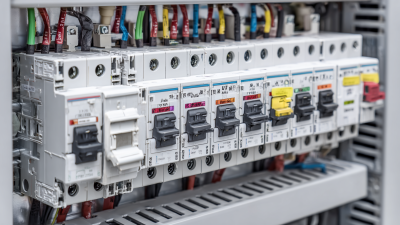

When evaluating the landscape of magnetic contactors, a comparative analysis of leading brands reveals critical insights into their performance, reliability, and overall functionality. These devices serve as pivotal components in controlling electrical systems, facilitating the safe operation of various industrial applications. Key factors such as current rating, coil voltage options, and operating temperature ranges are essential when assessing the suitability of different products for specific tasks.

Brands often differentiate themselves based on innovative features that enhance user convenience and efficiency. Some contactors may offer advanced thermal overload protection or easy integration with automation systems, while others emphasize durability and resistance to environmental factors. Understanding these traits allows users to make informed choices, aligning their operational requirements with the best-suited product options available in the market.

Moreover, the quality of materials used in the construction of magnetic contactors significantly impacts their longevity and reliability. Evaluating the internal mechanisms and build quality can highlight important distinctions that contribute to performance under demanding conditions. The comparative analysis of these elements empowers engineers and technicians to select effective solutions tailored to their specific electrical control needs.

The Best 10 Magnetic Contactors for Reliable Electrical Control

| Model |

Voltage Rating (V) |

Current Rating (A) |

Number of Poles |

Coil Voltage (V) |

Operating Temperature (°C) |

Additional Features |

| Model A |

230 |

16 |

3 |

110 |

-10 to 60 |

Built-in surge protection |

| Model B |

400 |

25 |

4 |

220 |

-25 to 70 |

IP66 rated |

| Model C |

480 |

32 |

3 |

24 |

-10 to 50 |

Silent operation |

| Model D |

230 |

20 |

2 |

120 |

-20 to 60 |

Energy efficient |

| Model E |

300 |

18 |

3 |

240 |

-5 to 55 |

Low power consumption |

| Model F |

350 |

15 |

2 |

120 |

-15 to 65 |

With LED indicator |

| Model G |

380 |

22 |

3 |

240 |

-10 to 60 |

Quick connect terminals |

| Model H |

220 |

30 |

4 |

110 |

-20 to 70 |

Compact design |

| Model I |

240 |

15 |

2 |

120 |

-30 to 60 |

Long life cycle |

| Model J |

460 |

35 |

3 |

240 |

-10 to 65 |

High efficiency |

Installation and Maintenance Tips for Optimal Performance of Contactors

When it comes to maintaining optimal performance in electrical control systems, the installation and maintenance of magnetic contactors play a crucial role. According to a report by the International Electrotechnical Commission, improper installation can lead to a staggering 30% increase in equipment failure rates. Therefore, adherence to proper installation guidelines is essential. This includes ensuring that contactors are correctly aligned, securely mounted, and properly wired, which not only enhances their longevity but also contributes to overall system reliability.

Regular maintenance is equally important in maximizing the efficiency of magnetic contactors. The National Electrical Manufacturers Association emphasizes that routine inspections can significantly reduce downtime and repair costs—by as much as 25%. Essential maintenance tasks include cleaning contact surfaces to prevent oxidation, checking for loose connections that can lead to overheating, and testing coil voltages to ensure they are within specified ranges. Implementing a preventive maintenance schedule allows for the early detection of potential issues, ultimately safeguarding the performance of electrical systems and prolonging equipment lifespan.

The Best 10 Magnetic Contactors for Reliable Electrical Control

Home

About Us

Products

Terminal Power Distribution Electric

AC Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

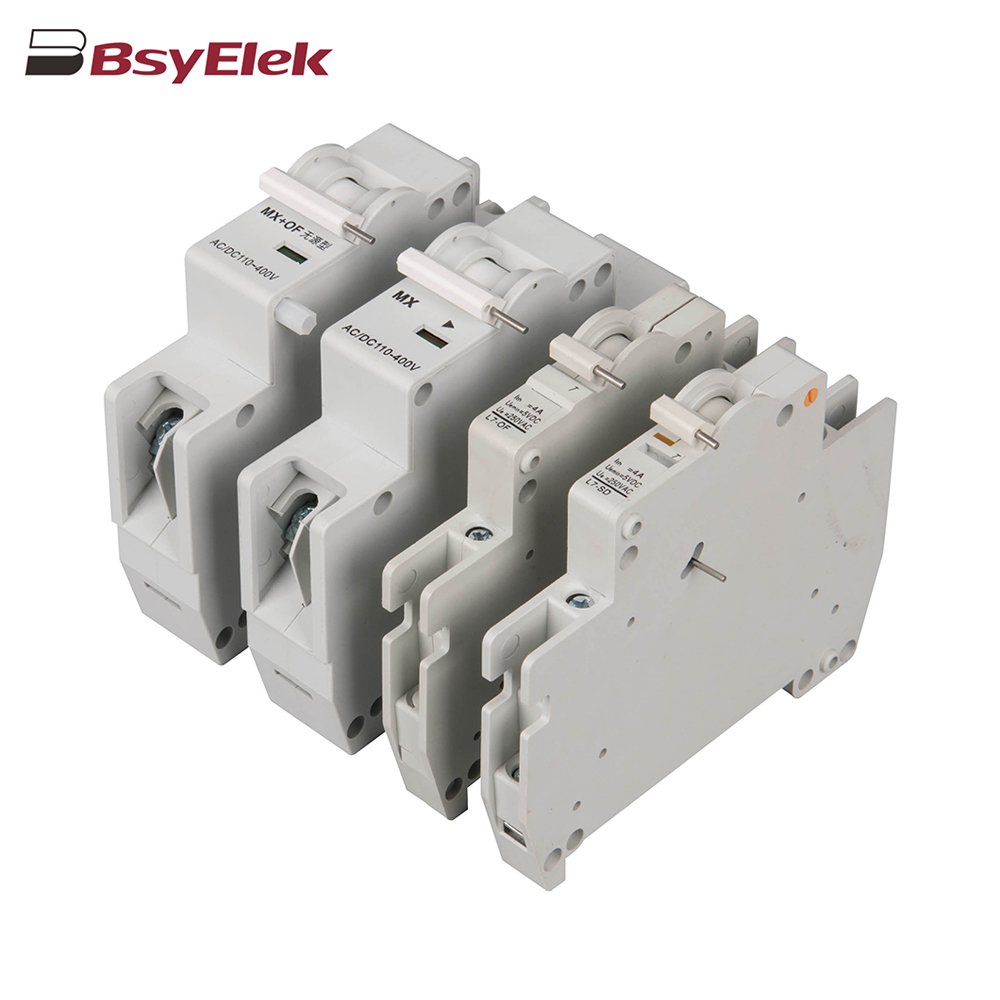

MCB Accessories

Main Switch

RCBO RCCB

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

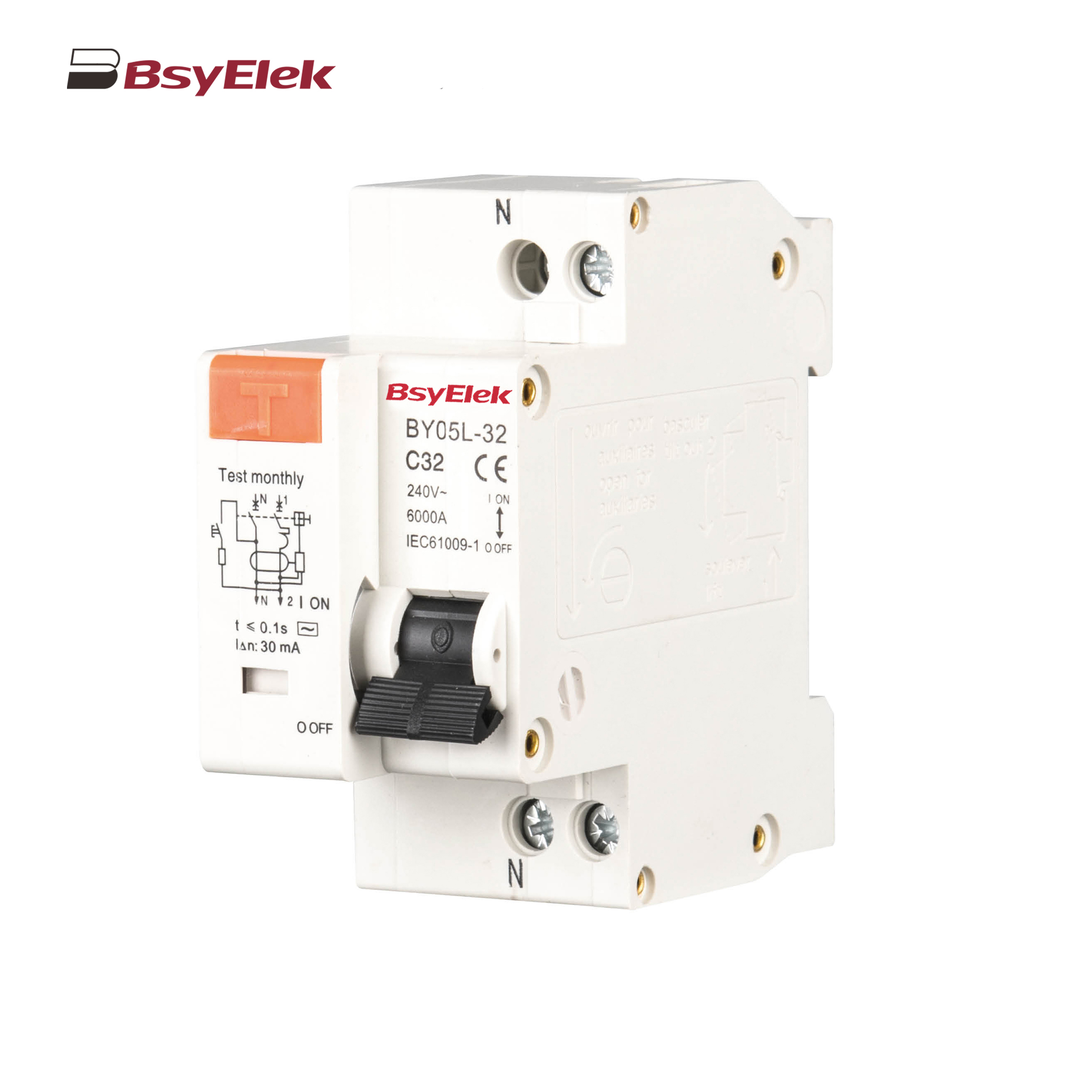

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

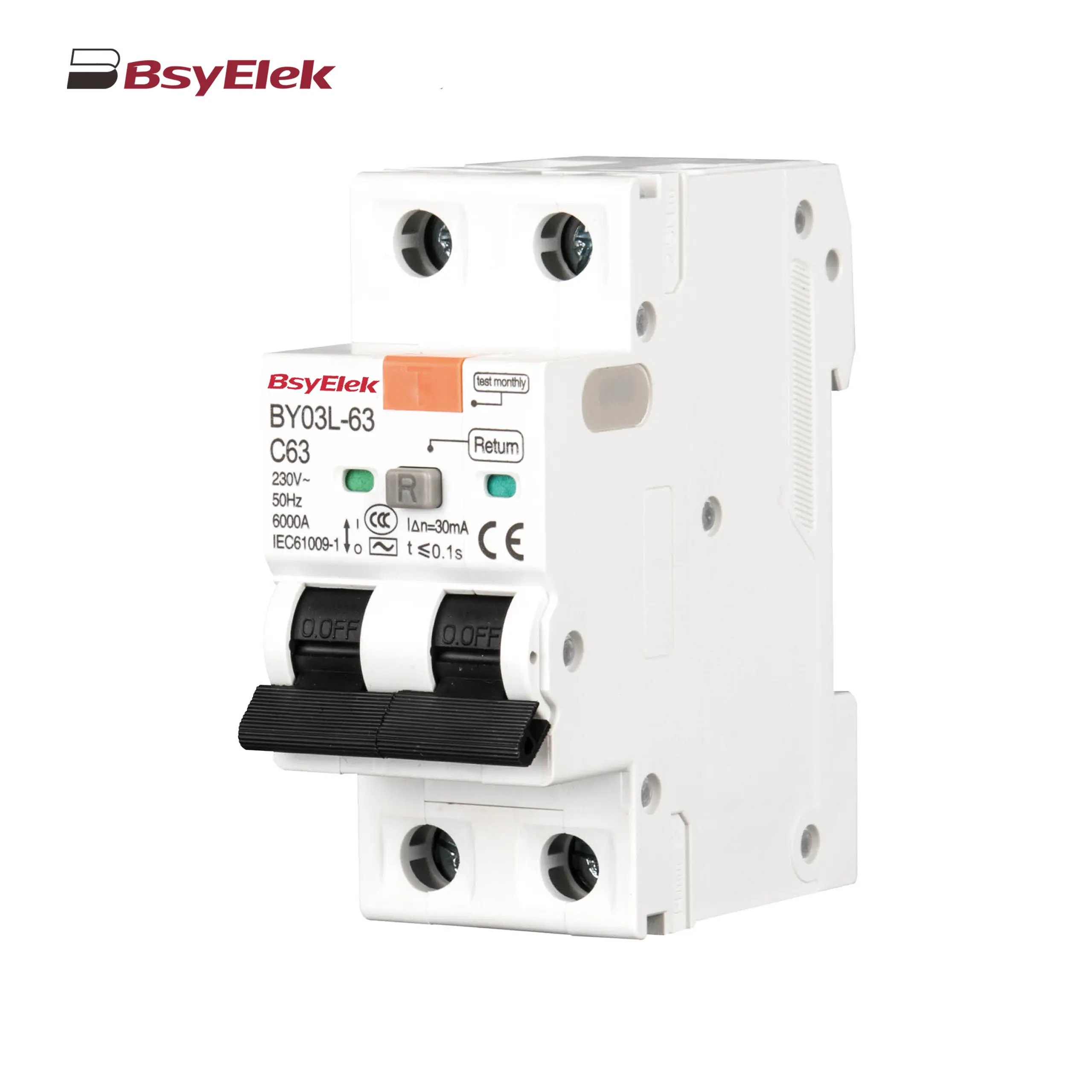

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

Resettable Overvoltage and Undervoltage Protector

AC Contactor

AC Surge Protective Device

Changeover Switch

Photovoltaic System Protection

DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

RCD

DC Surge Protective Device

DC Fuse

PV Isolator Switch

PV Connector

Cable Gland

PV Cable

PV Knife Switch

DC Molded Case Circuit Breaker

Industrial Power Distribution Electric

Distribution Box

Air Conditioning System

Definite Purpose Magnetic Contactor

Condensate Pump

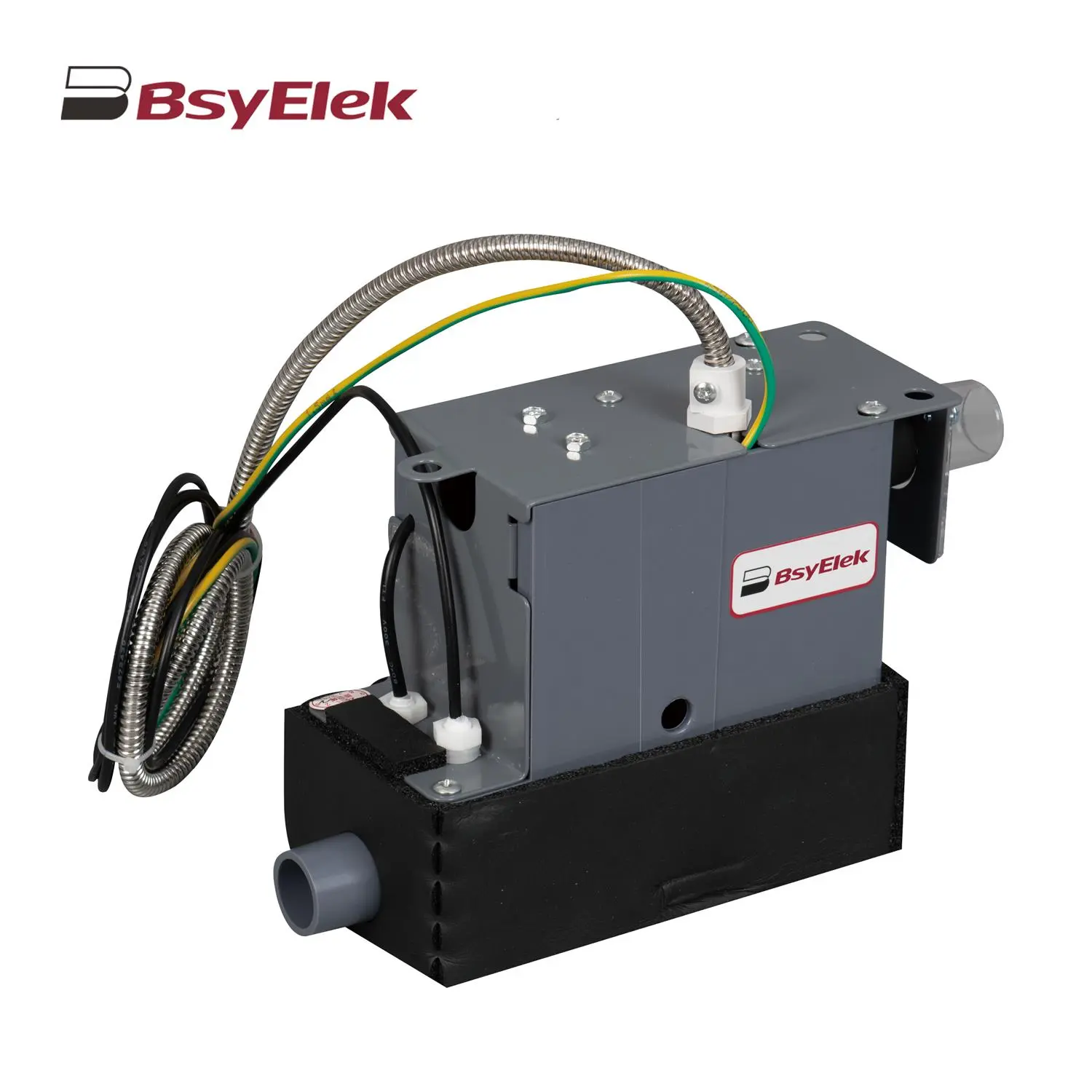

BY-5018 1.8M Engineering Drainage Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-24B/40B 10M Split Type Drainage Pump

BY-24B/40B 10M Split Type Drainage Pump

BY-100L 2M Drainage Pump of Air Conditioner

BY-100L 2M Drainage Pump of Air Conditioner

BY-360L 6M Large Displacement Drainage Pump

BY-360L 6M Large Displacement Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

News

Top Blog

Company News

Industry Dynamics

What is a miniature circuit breaker (MCB)?

PG Series Waterproof Cable Glands with Washer for Harsh Environments

LWSF-125 125A Manual Changeover Switch ensures reliable power transfer

BYX2 AC contactor series: reliable power control for modern electrical systems

High-performance 1000V DC fuse holder optimizes solar photovoltaic system protection

BY07L-63 Residual Current Circuit Breaker Ensures Global Electrical Safety

BYQ5 ATS Isolation Dual Power Automatic Transfer Switch

BY19G 63A Manual Changeover Switch: Features and Benefits

Support

Blog

Contact Us

OF SD MX OF MCB Miniature Circuit Breaker Accessories

OF SD MX OF MCB Miniature Circuit Breaker Accessories BYG1-125 Main Switch MCB Isolator Switch

BYG1-125 Main Switch MCB Isolator Switch BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector

BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector

BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector BYX2 6-95A AC Contactor

BYX2 6-95A AC Contactor BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device

BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device

BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device

BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device BY19G 63A Manual Changeover Switch

BY19G 63A Manual Changeover Switch LWSF-125 125A Manual Changeover Switch

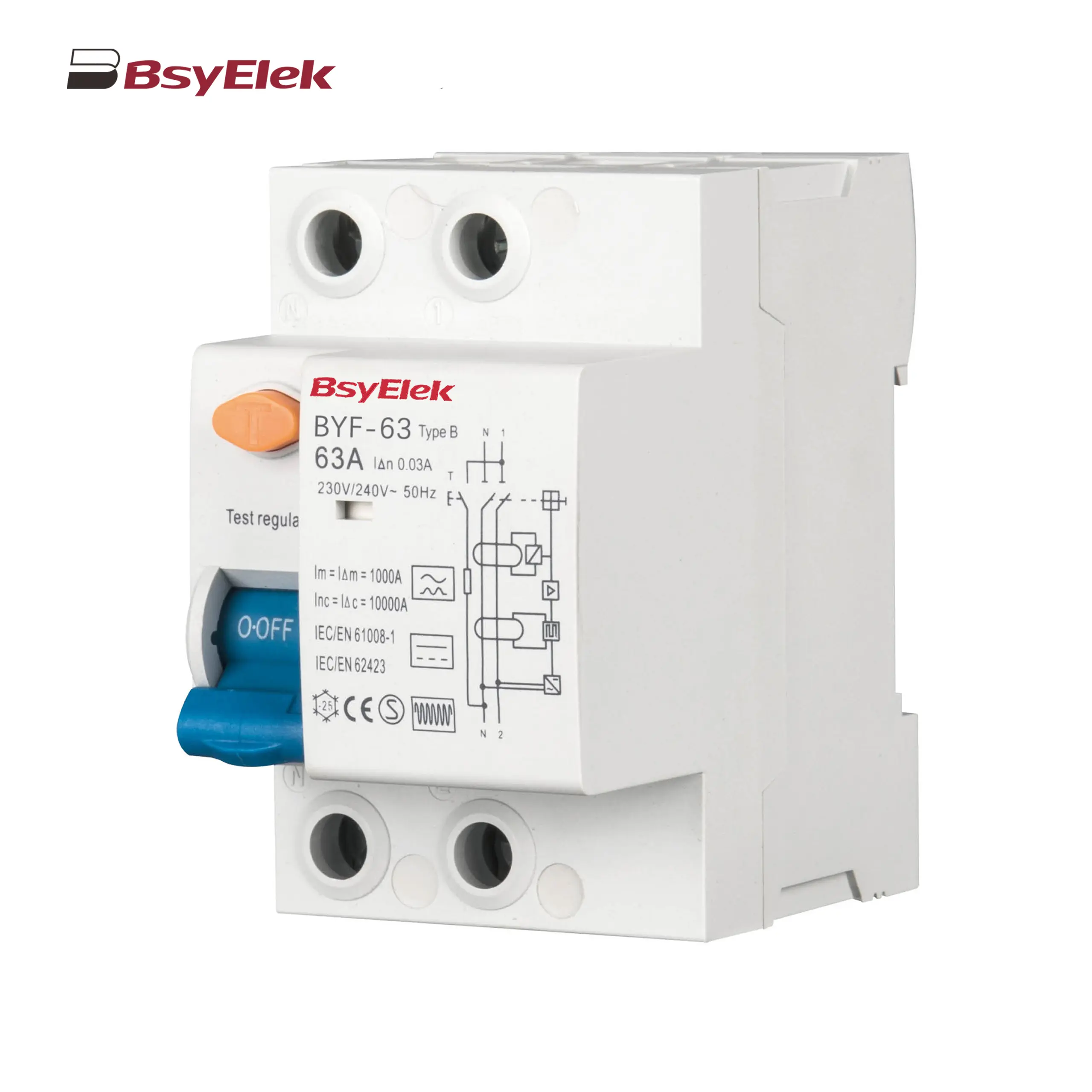

LWSF-125 125A Manual Changeover Switch BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device

BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device

BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device

BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link

BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link

BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link BYPV-ELR2 PV Isolator Switch with Enclosed Version

BYPV-ELR2 PV Isolator Switch with Enclosed Version BYPV-ELR1 PV Isolator Switch with Enclosed Version

BYPV-ELR1 PV Isolator Switch with Enclosed Version BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle

BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle BYPV-NL1 PV Isolator Switch with Lever Handle

BYPV-NL1 PV Isolator Switch with Lever Handle BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle

BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle PV-BY-01 30A/50A 1000V Photovoltaic Connector

PV-BY-01 30A/50A 1000V Photovoltaic Connector PV-BY-02 30A/50A 1500V Photovoltaic Connector

PV-BY-02 30A/50A 1500V Photovoltaic Connector PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector

PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector PV-BY-F01 30A 1500V Diode/Fuse Type Connector

PV-BY-F01 30A 1500V Diode/Fuse Type Connector PV-BY-T 50A 1500V T Type Branch Connector

PV-BY-T 50A 1500V T Type Branch Connector PV-BY-Y 30A 1500V Y Type Branch Connector

PV-BY-Y 30A 1500V Y Type Branch Connector PG Waterproof Cable Gland with Washer

PG Waterproof Cable Gland with Washer Photovoltaic Cable

Photovoltaic Cable HD11N Photovoltaic Knife Switch

HD11N Photovoltaic Knife Switch BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker

BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker

BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker BYM1E MCCB Electronic Type Molded Case Circuit Breaker

BYM1E MCCB Electronic Type Molded Case Circuit Breaker BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker

BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker BYW1 ACB Intelligent Universal Air Circuit Breaker

BYW1 ACB Intelligent Universal Air Circuit Breaker BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch

BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch Stainless Steel Hinge Type Electrical Box

Stainless Steel Hinge Type Electrical Box HA Waterproof Distribution Box

HA Waterproof Distribution Box HT Waterproof Distribution Box

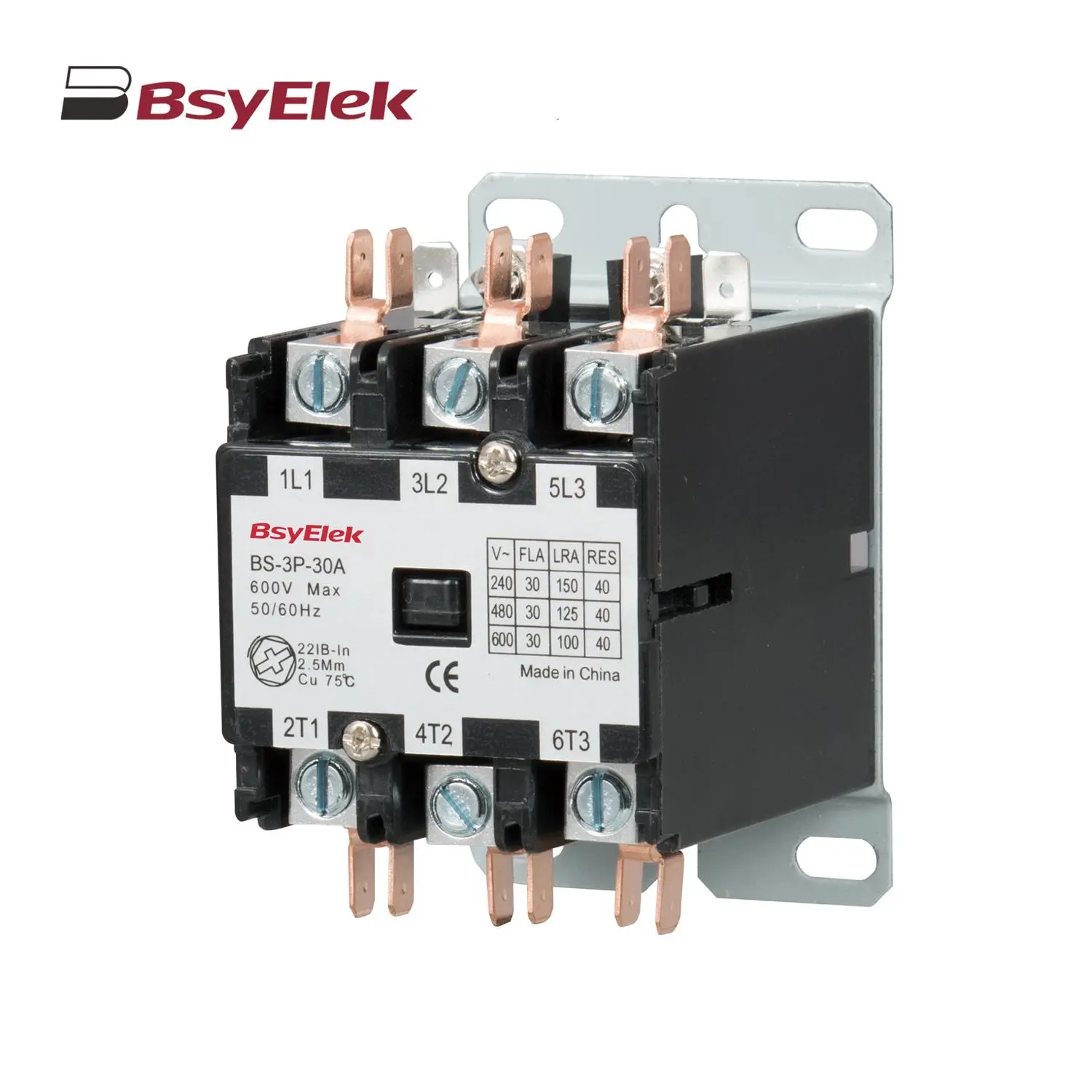

HT Waterproof Distribution Box BS Definite Purpose Magnetic AC Contactor

BS Definite Purpose Magnetic AC Contactor