5 Best Features of Waterproof Cable Gland for Ultimate Protection

In today's industrial landscape, the importance of reliable electrical connections cannot be overstated, particularly in environments exposed to moisture and harsh conditions. A crucial component in ensuring such reliability is the Waterproof Cable Gland, which acts as a barrier against water ingress and provides optimal protection for electrical and communication cables. According to a recent report from MarketsandMarkets, the global cable gland market is projected to reach USD 2.69 billion by 2026, growing at a CAGR of 5.6%. This growth underscores the increasing awareness of safety and efficiency in various sectors, including manufacturing, oil and gas, and renewable energy. By understanding the five best features of Waterproof Cable Glands, industry professionals can enhance their operational safety and minimize the risks associated with electrical failures.

Top Benefits of Waterproof Cable Glands for Electrical Safety

Waterproof cable glands are essential components in modern electrical systems, especially in environments prone to moisture and dust. The primary benefit of these glands is their ability to provide a robust barrier against water ingress, safeguarding electrical connections from potential damage. This protection not only enhances the longevity of the equipment but also ensures operational reliability, reducing the risk of unexpected failures and costly repairs.

When installing waterproof cable glands, it’s crucial to select the right size and material according to your specific application. Tips for achieving optimal performance include ensuring proper sealing during installation and regularly checking for wear and tear. Additionally, use glands with an IP rating suitable for your environment; for example, IP68 is ideal for submersible applications.

In terms of safety, waterproof cable glands contribute to preventing electrical hazards by minimizing short circuits caused by water exposure. This is particularly important in industrial settings where equipment operates under harsh conditions. Remember to follow manufacturer guidelines for maintenance to ensure that the protective features of the glands remain effective over time, keeping both personnel and equipment safe.

5 Best Features of Waterproof Cable Gland for Ultimate Protection - Top Benefits of Waterproof Cable Glands for Electrical Safety

| Feature |

Description |

Benefits |

| IP Rating |

Indicates the level of protection against dust and water ingress. |

Ensures reliable performance in harsh environments. |

| Material Quality |

Made from durable materials like stainless steel or nylon. |

Provides longevity and resistance to corrosion. |

| Easy Installation |

Designed for quick and easy mounting. |

Reduces installation time and labor costs. |

| Chemical Resistance |

Can withstand exposure to various chemicals and solvents. |

Ensures reliability in industrial applications. |

| Flexibility |

Available in various sizes and configurations. |

Accommodates a wide range of cable types and applications. |

Understanding the Role of Seal Materials in Waterproof Cable Glands

The role of seal materials in waterproof cable glands is paramount for ensuring optimal protection against moisture and environmental contaminants. These seals act as barriers that prevent water penetration and safeguard the integrity of electrical connections.

Common materials used for seals include rubber compounds, silicone, and elastomers, each offering unique benefits. For instance, silicone seals provide excellent flexibility and resilience under varying temperatures, while rubber compounds offer robust durability, making them ideal for outdoor applications where exposure to harsh weather conditions is common.

In addition to preventing water ingress, the choice of seal material impacts the overall performance and longevity of the cable gland. High-quality seal materials can withstand pressure, resist chemical degradation, and maintain their sealing properties over time. This resilience ensures that the electrical systems remain functional and safe, particularly in environments subject to vibration, movement, or extreme temperatures. Understanding the properties and applications of these seal materials is essential for selecting the right waterproof cable gland for specific needs, thereby enhancing reliability and safety in electrical installations.

Key Installation Techniques for Ensuring Maximum Waterproofing

When it comes to waterproof cable glands, ensuring maximum waterproofing is essential for durability and safety. A key installation technique is the proper use of sealing elements. According to industry reports, about 30% of equipment failures in harsh environments are due to inadequate sealing. Therefore, selecting the right cable gland with integrated sealing materials, such as rubber or silicone, can significantly enhance waterproof performance.

Another critical aspect is the correct torque specification during installation. Over-tightening can compromise the integrity of the seal, while under-tightening can lead to leakage. Studies indicate that applying the manufacturer-recommended torque can improve the seal's resistance to water ingress by up to 40%. Additionally, when working with metal roofs, special attention should be given to the compatibility of the cable gland materials with the roofing structure to prevent corrosion-related issues that could undermine waterproofing.

Lastly, utilizing heat-shrink tubing or alternative insulating materials over the cables prior to installation can provide an extra layer of protection. Research shows that this method has been effective in maintaining insulation integrity in applications exposed to moisture and extreme weather, thus extending the lifecycle of the entire system. Implementing these installation techniques will ensure maximum waterproofing and reliability in any environment.

Comparative Analysis of Waterproof Cable Glands vs. Standard Options

When it comes to cable management in environments exposed to moisture, the choice between waterproof cable glands and standard options is critical for ensuring long-term performance and reliability. According to a report by Global Market Insights, the waterproof cable gland market is projected to witness a compound annual growth rate (CAGR) of over 5% from 2021 to 2027. This growth can be attributed to the increasing demand for enhanced protection in sectors such as marine, telecommunications, and renewable energy.

Waterproof cable glands provide superior sealing and ingress protection (IP), which is vital in preventing the entry of water and contaminants. For instance, while standard cable glands typically offer an IP rating of 54, waterproof options can achieve ratings up to IP68 or higher, allowing them to withstand submersion in water for prolonged periods. A study published by the Electrical and Electronics Engineers Society highlighted that equipment failures due to water ingress could lead to repair costs exceeding 40% of initial installation expenses, reinforcing the importance of investing in high-quality waterproof solutions for critical applications.

Maintenance Tips for Optimizing the Lifespan of Waterproof Cable Glands

Maintaining waterproof cable glands is pivotal for enhancing the longevity and reliability of electrical installations in harsh environments. According to a report by Global Market Insights, the waterproof cable gland market is expected to grow significantly, with a projected CAGR of over 5% through 2027. This growth underscores the importance of ensuring that these components are properly maintained.

Regular inspections for wear and tear, exposure to UV light, and environmental factors can significantly impact their functionality. To maximize lifespan, users should consider implementing a routine maintenance schedule, replacing seals and gaskets as needed, and ensuring that the installation complies with relevant standards.

In addition to inspections, the choice of the right materials for the cable gland is crucial. Research indicates that using materials like polyamide or brass can offer superior resistance to environmental challenges, which is vital in sectors such as oil and gas, where waterproof integrity is non-negotiable.

Moreover, applying appropriate lubricants during installation can prevent damage to seals and enhance the gland’s resistance to moisture ingress. A study published in the Journal of Electrical Engineering highlights that proper sealing techniques can reduce failure rates by up to 30%, making it essential for users to invest time and resources into optimal maintenance practices.

Home

About Us

Products

Terminal Power Distribution Electric

AC Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

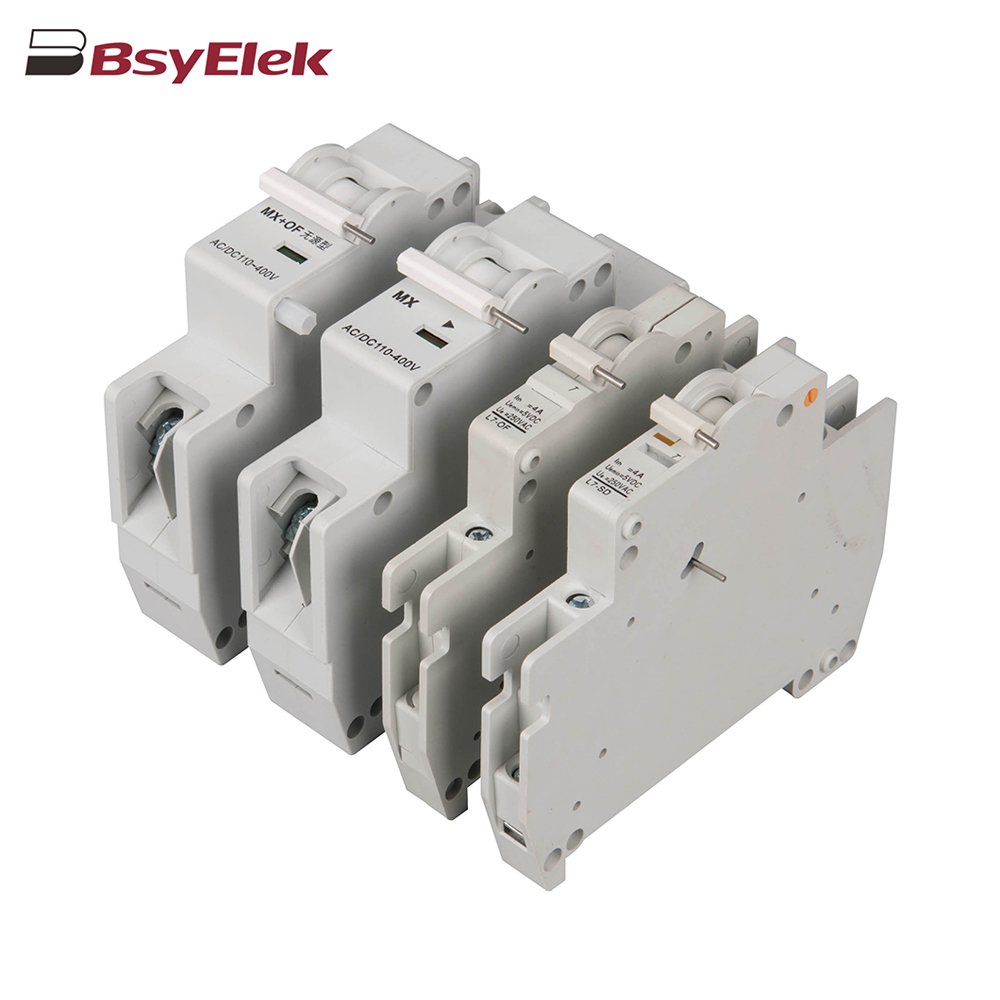

MCB Accessories

Main Switch

RCBO RCCB

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

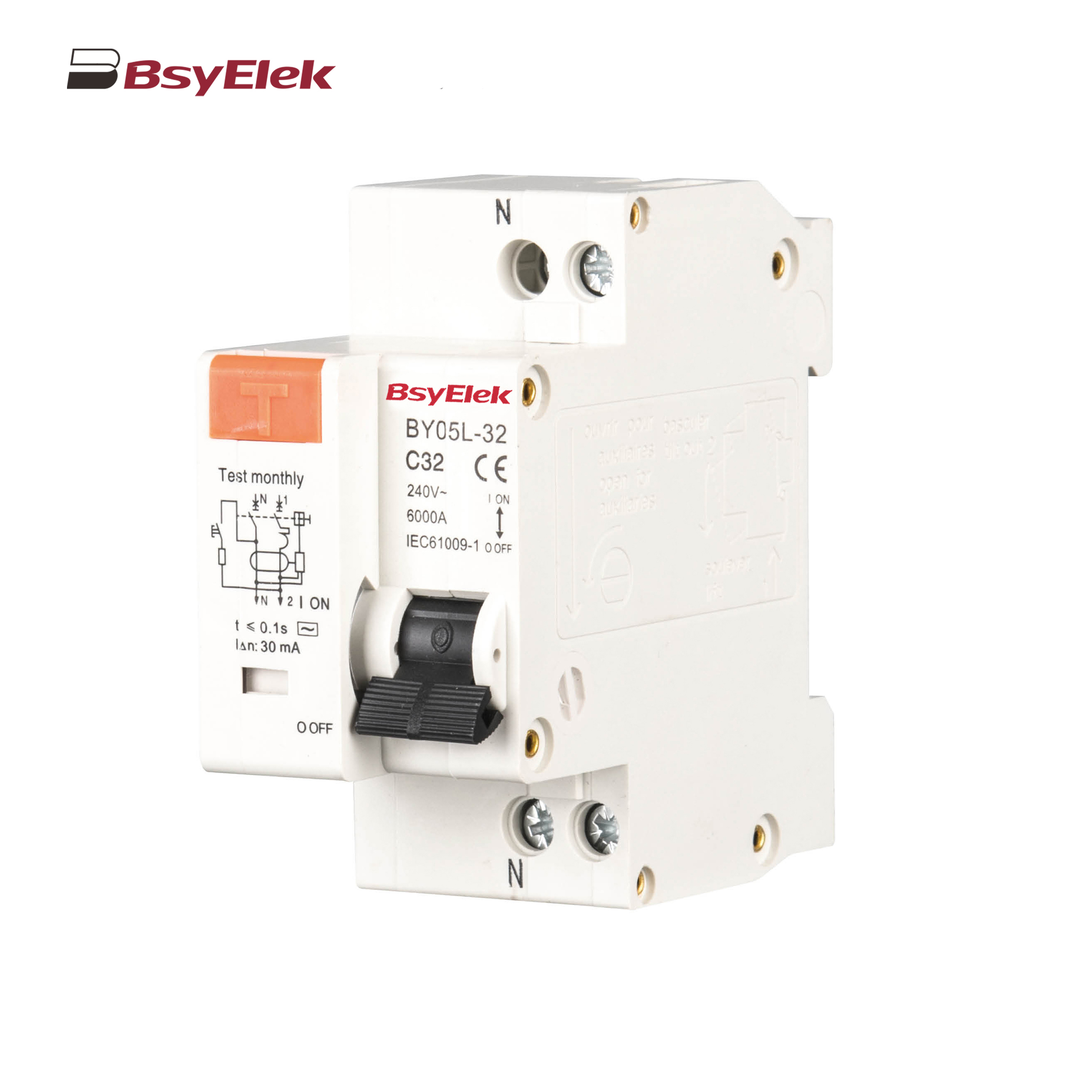

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

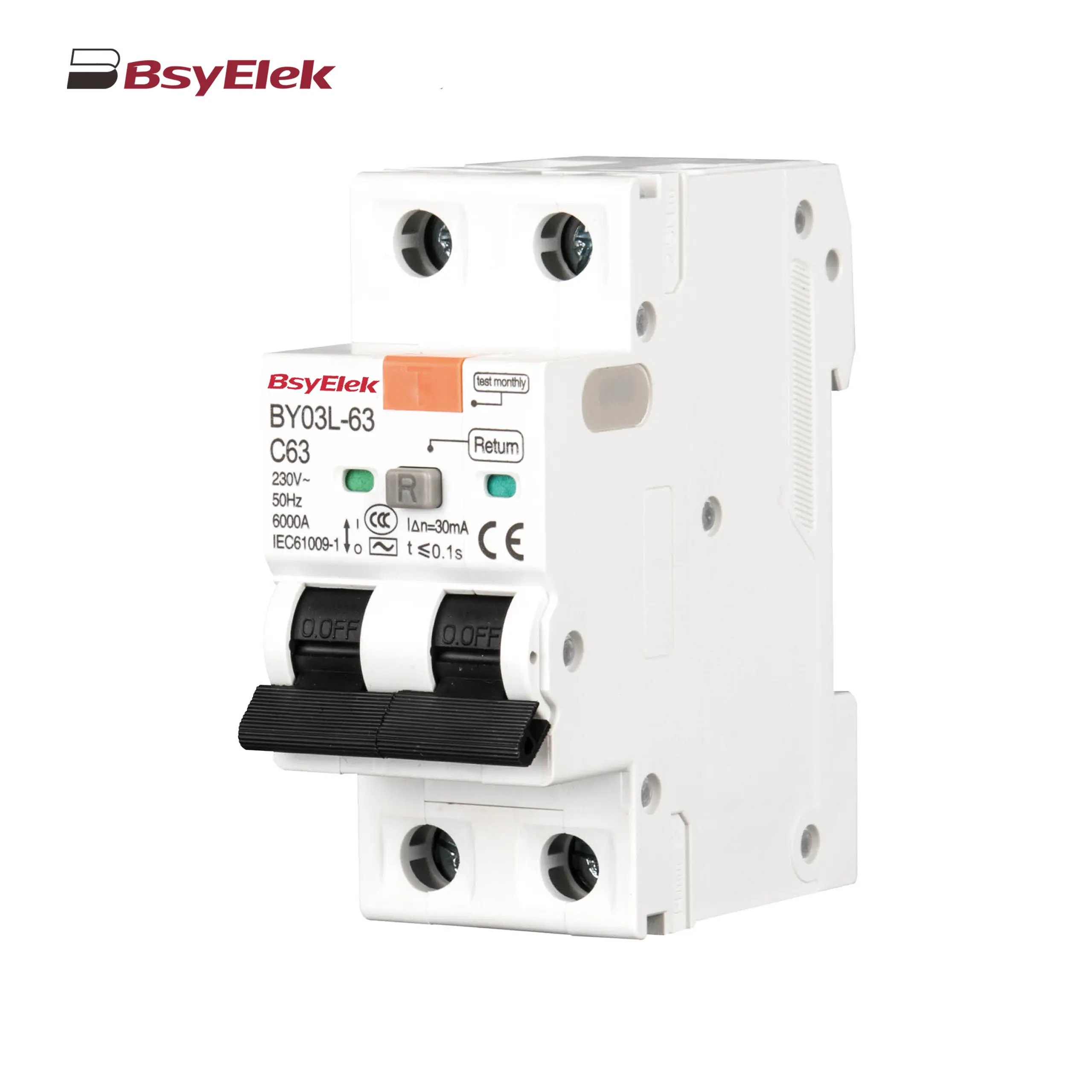

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

Resettable Overvoltage and Undervoltage Protector

AC Contactor

AC Surge Protective Device

Changeover Switch

Photovoltaic System Protection

DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

RCD

DC Surge Protective Device

DC Fuse

PV Isolator Switch

PV Connector

Cable Gland

PV Cable

PV Knife Switch

DC Molded Case Circuit Breaker

Industrial Power Distribution Electric

Distribution Box

Air Conditioning System

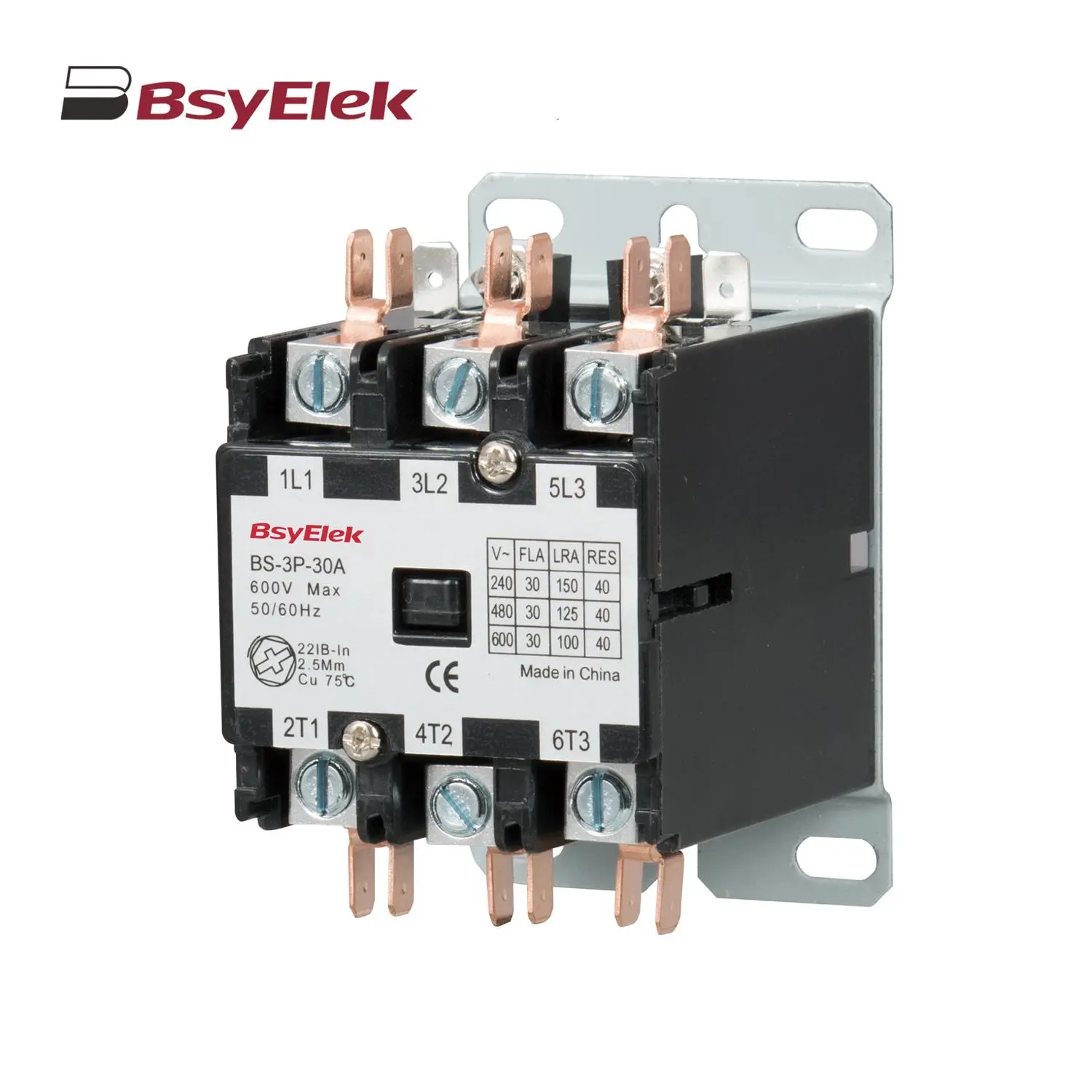

Definite Purpose Magnetic Contactor

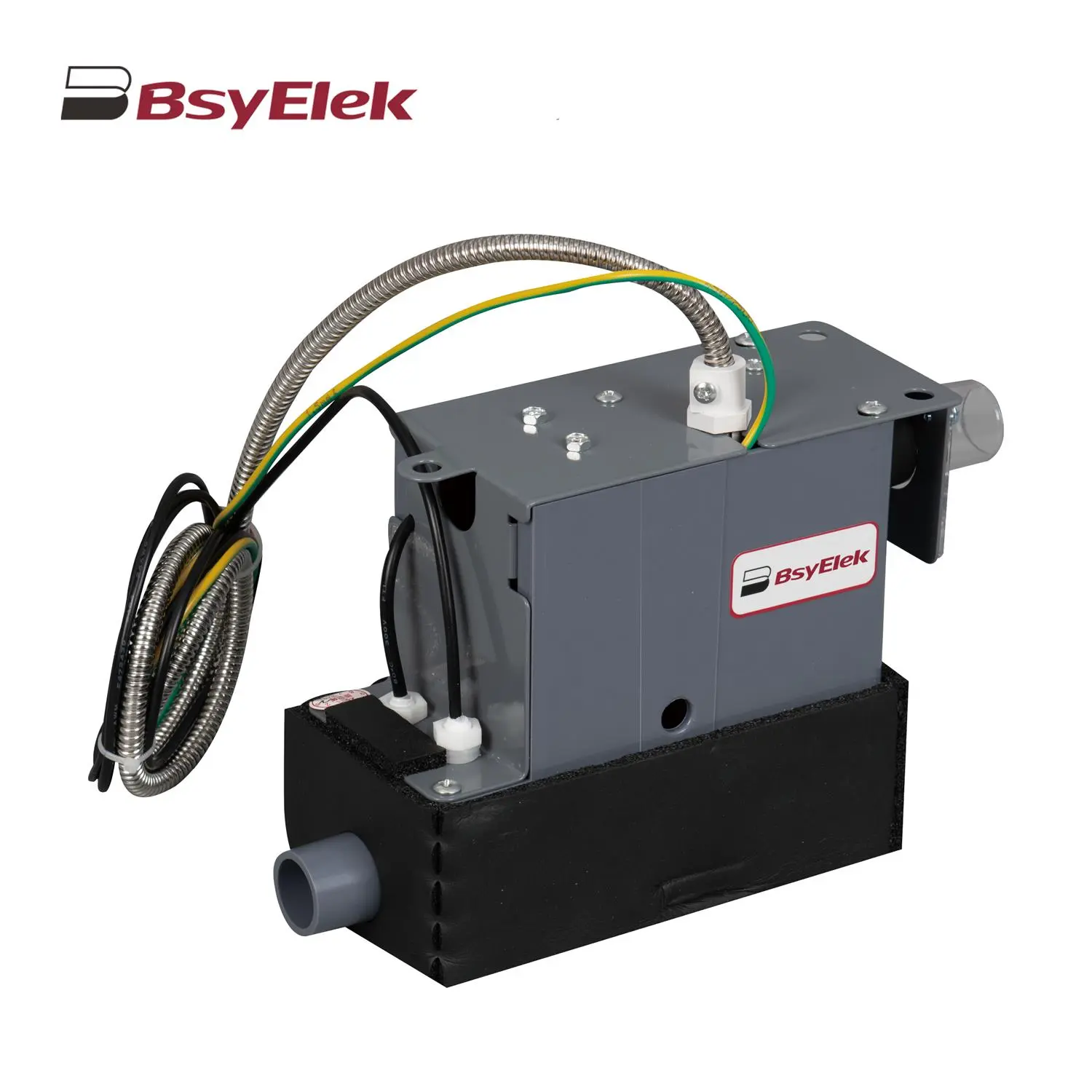

Condensate Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-24B/40B 10M Split Type Drainage Pump

BY-24B/40B 10M Split Type Drainage Pump

BY-100L 2M Drainage Pump of Air Conditioner

BY-100L 2M Drainage Pump of Air Conditioner

BY-360L 6M Large Displacement Drainage Pump

BY-360L 6M Large Displacement Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

News

Top Blog

Company News

Industry Dynamics

What is a miniature circuit breaker (MCB)?

PG Series Waterproof Cable Glands with Washer for Harsh Environments

LWSF-125 125A Manual Changeover Switch ensures reliable power transfer

BYX2 AC contactor series: reliable power control for modern electrical systems

High-performance 1000V DC fuse holder optimizes solar photovoltaic system protection

BY07L-63 Residual Current Circuit Breaker Ensures Global Electrical Safety

BYQ5 ATS Isolation Dual Power Automatic Transfer Switch

BY19G 63A Manual Changeover Switch: Features and Benefits

Support

Blog

Contact Us

OF SD MX OF MCB Miniature Circuit Breaker Accessories

OF SD MX OF MCB Miniature Circuit Breaker Accessories BYG1-125 Main Switch MCB Isolator Switch

BYG1-125 Main Switch MCB Isolator Switch BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector

BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector

BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector BYX2 6-95A AC Contactor

BYX2 6-95A AC Contactor BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device

BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device

BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device

BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device BY19G 63A Manual Changeover Switch

BY19G 63A Manual Changeover Switch LWSF-125 125A Manual Changeover Switch

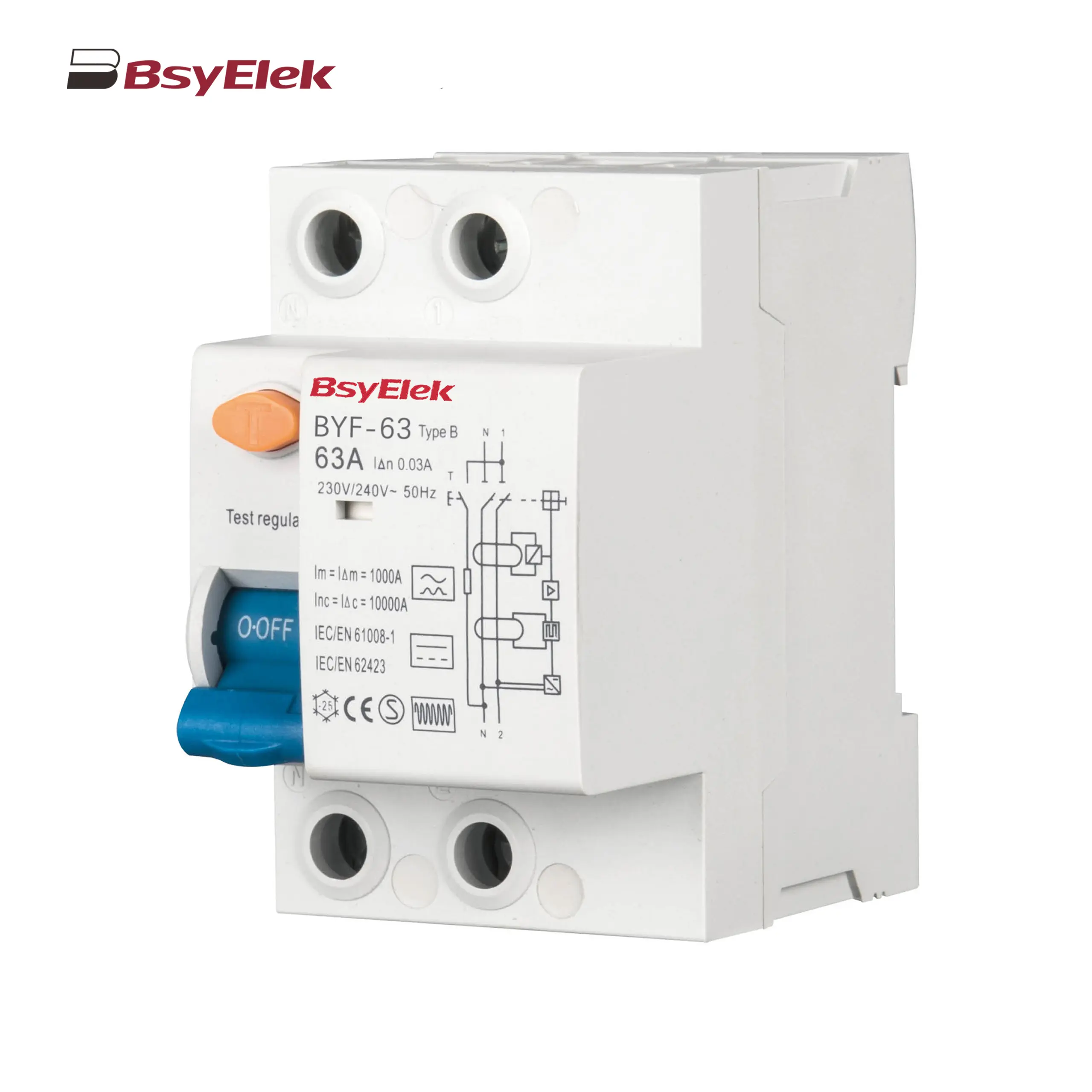

LWSF-125 125A Manual Changeover Switch BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device

BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device

BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device

BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link

BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link

BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link BYPV-ELR2 PV Isolator Switch with Enclosed Version

BYPV-ELR2 PV Isolator Switch with Enclosed Version BYPV-ELR1 PV Isolator Switch with Enclosed Version

BYPV-ELR1 PV Isolator Switch with Enclosed Version BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle

BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle BYPV-NL1 PV Isolator Switch with Lever Handle

BYPV-NL1 PV Isolator Switch with Lever Handle BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle

BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle PV-BY-01 30A/50A 1000V Photovoltaic Connector

PV-BY-01 30A/50A 1000V Photovoltaic Connector PV-BY-02 30A/50A 1500V Photovoltaic Connector

PV-BY-02 30A/50A 1500V Photovoltaic Connector PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector

PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector PV-BY-F01 30A 1500V Diode/Fuse Type Connector

PV-BY-F01 30A 1500V Diode/Fuse Type Connector PV-BY-T 50A 1500V T Type Branch Connector

PV-BY-T 50A 1500V T Type Branch Connector PV-BY-Y 30A 1500V Y Type Branch Connector

PV-BY-Y 30A 1500V Y Type Branch Connector PG Waterproof Cable Gland with Washer

PG Waterproof Cable Gland with Washer Photovoltaic Cable

Photovoltaic Cable HD11N Photovoltaic Knife Switch

HD11N Photovoltaic Knife Switch BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker

BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker

BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker BYM1E MCCB Electronic Type Molded Case Circuit Breaker

BYM1E MCCB Electronic Type Molded Case Circuit Breaker BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker

BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker BYW1 ACB Intelligent Universal Air Circuit Breaker

BYW1 ACB Intelligent Universal Air Circuit Breaker BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch

BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch Stainless Steel Hinge Type Electrical Box

Stainless Steel Hinge Type Electrical Box HA Waterproof Distribution Box

HA Waterproof Distribution Box HT Waterproof Distribution Box

HT Waterproof Distribution Box BS Definite Purpose Magnetic AC Contactor

BS Definite Purpose Magnetic AC Contactor