Why You Need an Air Conditioner Pump for Optimal Cooling Efficiency

In today’s world of HVAC technology, the importance of optimal cooling efficiency cannot be overstated. According to the U.S. Department of Energy, air conditioning accounts for approximately 12% of total energy use in homes, making the efficiency of cooling systems a critical focus for both homeowners and industry professionals. One essential component of achieving optimal cooling is the Air Conditioner Pump. Renowned HVAC expert Dr. Emily Carter states, “Without a high-performing Air Conditioner Pump, even the most advanced cooling systems can underperform, causing unnecessary energy expenditure and discomfort.”

The role of the Air Conditioner Pump extends beyond mere cooling; it ensures the distribution of conditioned air throughout a space, dramatically impacting the overall performance and longevity of air conditioning units. Recent studies have indicated that homes equipped with reliable pumps can experience up to a 30% increase in energy efficiency, leading to substantial savings on energy bills. Furthermore, as climate change intensifies global temperatures, the demand for effective cooling solutions will only grow, underscoring the necessity for homeowners to invest in high-quality Air Conditioner Pumps. This guide will detail the top 10 reasons why selecting the right pump is vital for enhancing cooling efficiency and achieving cost-effective climate control.

The Importance of an Air Conditioner Pump in Your Cooling System

An air conditioner pump is a crucial component in your cooling system, directly impacting its efficiency and performance. According to the U.S. Department of Energy, proper airflow is essential for cooling efficiency, and a well-functioning pump ensures the optimal circulation of refrigerant and air throughout the system. This circulation aids in maintaining the ideal indoor temperatures, particularly during peak summer months when demand for cooling rises significantly.

Furthermore, industry reports suggest that homes without adequate air conditioning pumps often experience increased energy costs, as inefficient systems work harder to reach desired temperatures. A study by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) highlighted that systems with efficient pumps can reduce energy consumption by up to 30%. Therefore, investing in a quality air conditioner pump not only promotes a comfortable living environment but also enhances your system's energy efficiency, leading to long-term savings and reduced environmental impact.

Air Conditioner Pump Efficiency Comparison

This chart illustrates the impact of air conditioner pump efficiency on overall cooling performance. Higher efficiency levels correspond to better cooling percentages, showcasing the importance of a well-functioning pump in an air conditioning system.

How Air Conditioner Pumps Enhance Energy Efficiency

Air conditioner pumps play a crucial role in enhancing the energy efficiency of cooling systems. By effectively circulating refrigerant and ensuring proper drainage of condensate, these pumps help maintain optimal pressure levels within the system. This not only prevents the refrigerant from overheating but also allows the air conditioner to operate smoothly without unnecessary strain. The result is a more efficient cooling process that consumes less energy, ultimately leading to lower electricity bills.

Moreover, advanced air conditioner pumps can adapt to varying cooling demands, adjusting their output based on current indoor temperatures. This modulation minimizes energy wastage and ensures that the air conditioner provides consistent cooling when needed most. Additionally, pumps equipped with smart technology can offer real-time monitoring and diagnostics, allowing users to optimize settings and schedule maintenance effectively. Investing in a high-quality air conditioner pump can significantly reduce the overall carbon footprint while enhancing the longevity and performance of the cooling system.

Signs That Your Air Conditioner Pump Needs Maintenance

A well-functioning air conditioner pump is crucial for maintaining optimal cooling efficiency. According to recent industry reports, approximately 25% of air conditioning systems experience inefficiencies due to neglected pump maintenance. Recognizing the signs that your air conditioner pump needs attention can save you both money and energy.

One of the primary indicators of a struggling pump is unusual noise, such as grinding or whining sounds, which often signifies mechanical wear or blockage. Additionally, if you notice reduced airflow or inconsistent cooling throughout your space, this may indicate that the pump is failing to circulate refrigerant effectively. A study by the U.S. Department of Energy highlights that proper maintenance and timely repairs can enhance system efficiency by up to 15%, drastically reducing energy costs.

Another key sign to watch for is water accumulation or leaks near the unit. A malfunctioning pump can lead to excess condensation, which not only affects performance but can also result in mold growth and other structural issues. Regularly checking your pump and scheduling maintenance can help you avoid these costly problems, ensuring that your air conditioning system operates at its full potential.

Top Features to Look for in a Quality Air Conditioner Pump

When selecting an air conditioner pump, several key features can significantly influence the efficiency and longevity of your cooling system. Firstly, ensure that the pump has a robust flow rate. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), a pump with a flow rate optimized for your specific air system can enhance cooling efficiency by as much as 30%. This is crucial for maintaining optimal indoor temperatures during peak summer months.

Another essential feature is the presence of a reliable check valve, which prevents backflow and maintains consistent pressure within the system. Research from the International Institute of Refrigeration highlights that integrating a quality check valve can reduce energy consumption by 10% or more by minimizing unnecessary cycling of the pump. Additionally, look for pumps made with durable materials and backed by warranties, as longevity and reliability are vital for minimizing maintenance costs and ensuring long-term performance. By focusing on these features, you can make a well-informed choice that enhances your overall cooling experience.

Comparing Different Types of Air Conditioner Pumps for Optimal Performance

When choosing an air conditioner pump, it's important to compare the different types available to ensure optimal performance. The three main types of pumps are condensate pumps, sump pumps, and submersible pumps. Condensate pumps are specifically designed to handle the water produced by air conditioning units, efficiently removing excess moisture from your home’s atmosphere. This minimizes the risk of mold and improves indoor air quality.

Sump pumps, on the other hand, are generally used to prevent flooding in basements but can be adapted for use with air conditioning systems as well. They work by pumping water away from the area where it can accumulate, ensuring that your cooling system operates without interruption. Lastly, submersible pumps are versatile and can be used in various applications, including air conditioning. They sit directly in water and can efficiently expel water with minimal energy use, making them an effective choice for larger cooling systems. Understanding these differences can help homeowners select the pump that best suits their air conditioning needs, enhancing overall cooling efficiency.

Why You Need an Air Conditioner Pump for Optimal Cooling Efficiency

| Pump Type |

Cooling Efficiency (%) |

Noise Level (dB) |

Energy Consumption (kWh) |

Cost ($) |

| Scroll Pump |

90% |

45 |

0.75 |

300 |

| Centrifugal Pump |

85% |

60 |

1.00 |

250 |

| Diaphragm Pump |

80% |

50 |

0.60 |

200 |

| Positive Displacement Pump |

88% |

55 |

0.90 |

280 |

Home

About Us

Products

Terminal Power Distribution Electric

AC Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

MCB Accessories

Main Switch

RCBO RCCB

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

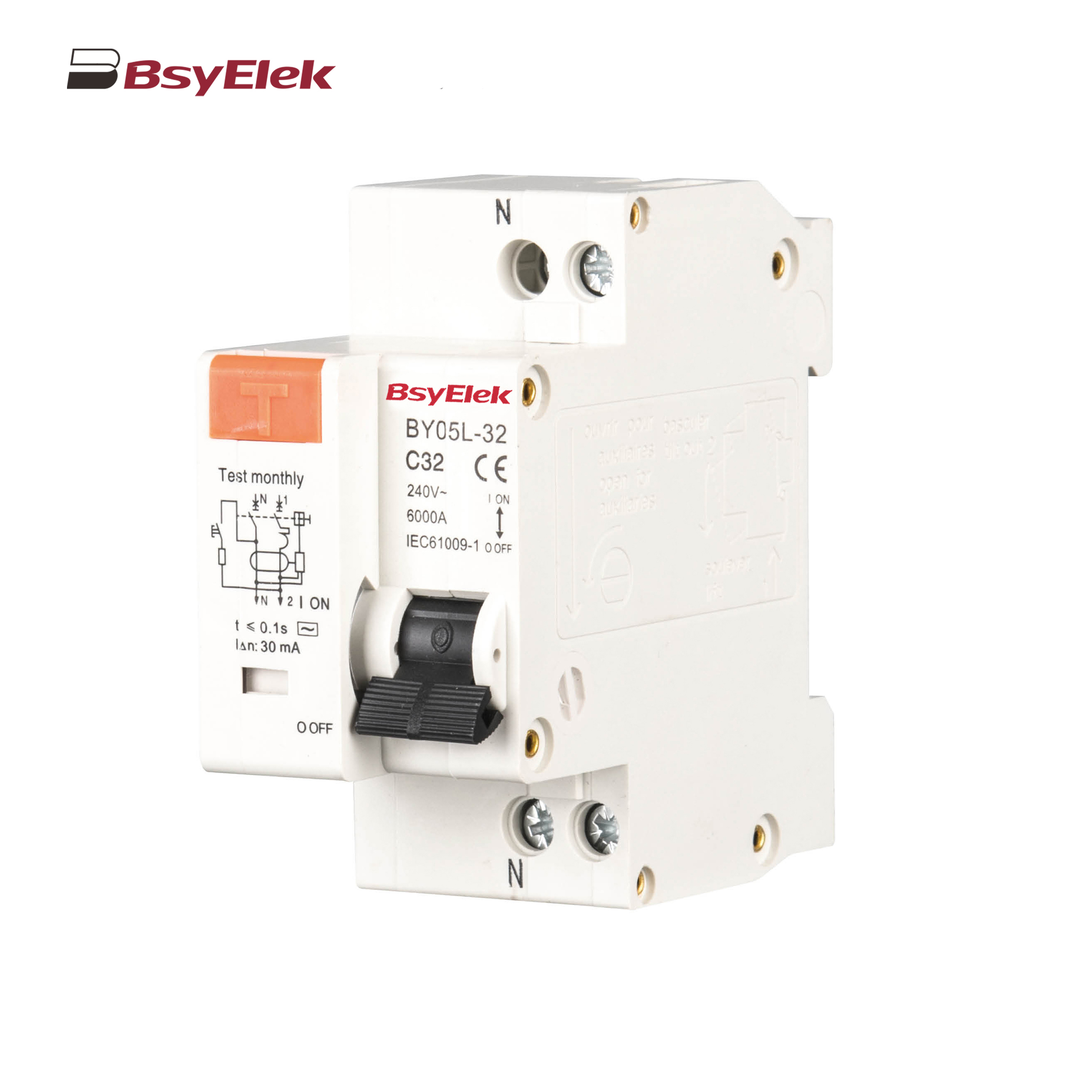

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

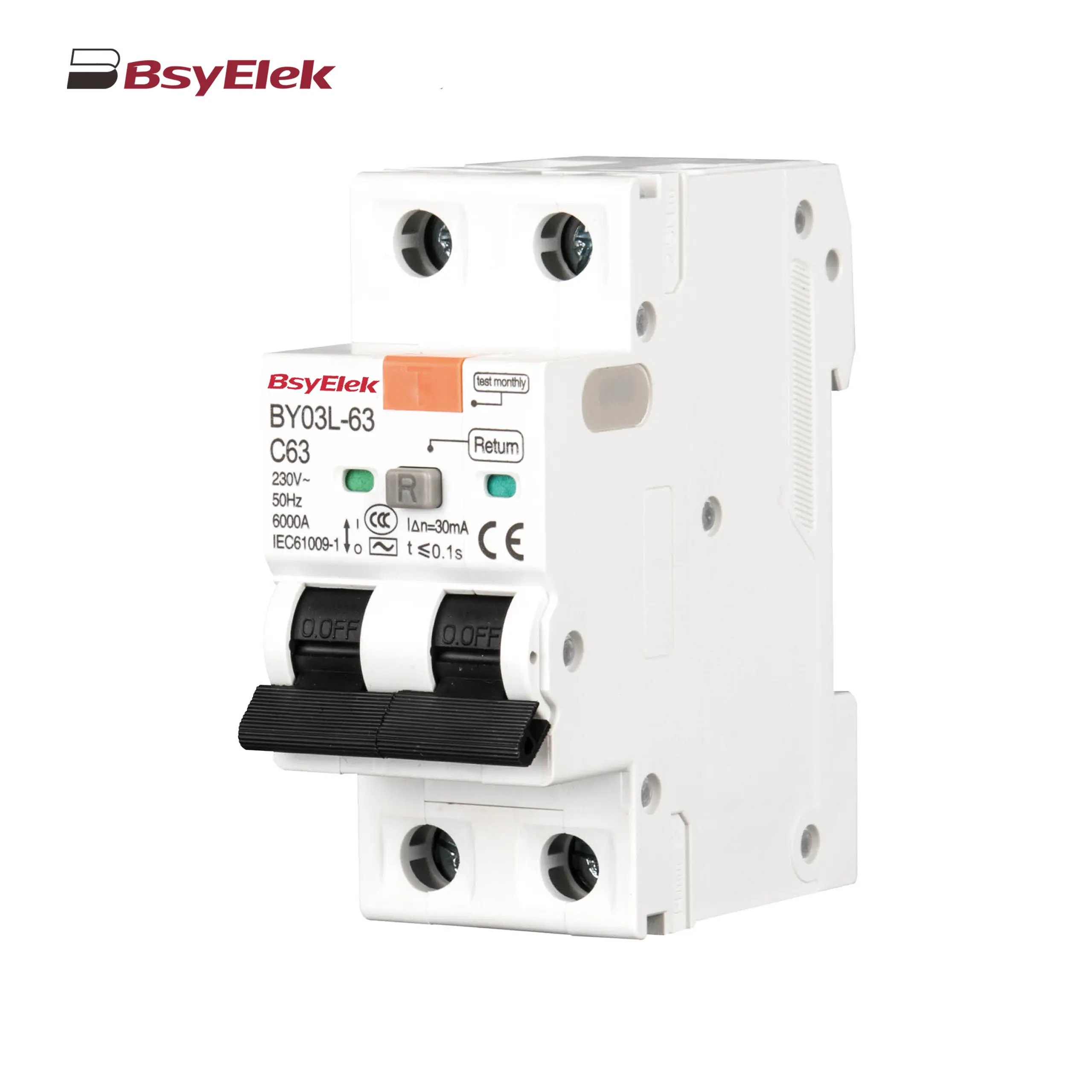

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

Resettable Overvoltage and Undervoltage Protector

AC Contactor

AC Surge Protective Device

Changeover Switch

Photovoltaic System Protection

DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

RCD

DC Surge Protective Device

DC Fuse

PV Isolator Switch

PV Connector

Cable Gland

PV Cable

PV Knife Switch

DC Molded Case Circuit Breaker

Industrial Power Distribution Electric

Distribution Box

Air Conditioning System

Definite Purpose Magnetic Contactor

Condensate Pump

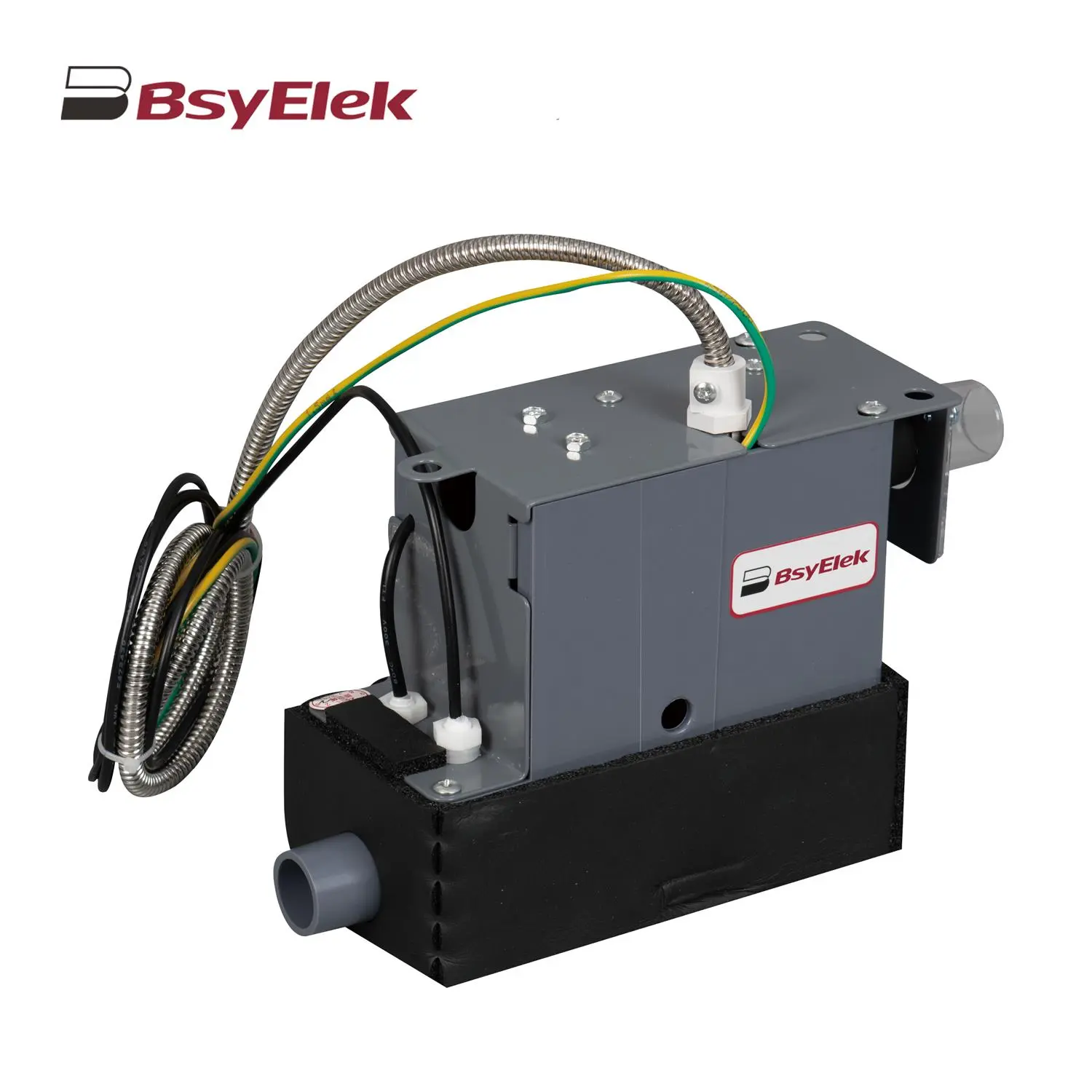

BY-5018 1.8M Engineering Drainage Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-24B/40B 10M Split Type Drainage Pump

BY-24B/40B 10M Split Type Drainage Pump

BY-100L 2M Drainage Pump of Air Conditioner

BY-100L 2M Drainage Pump of Air Conditioner

BY-360L 6M Large Displacement Drainage Pump

BY-360L 6M Large Displacement Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

News

Top Blog

Company News

Industry Dynamics

What is a miniature circuit breaker (MCB)?

PG Series Waterproof Cable Glands with Washer for Harsh Environments

LWSF-125 125A Manual Changeover Switch ensures reliable power transfer

BYX2 AC contactor series: reliable power control for modern electrical systems

High-performance 1000V DC fuse holder optimizes solar photovoltaic system protection

BY07L-63 Residual Current Circuit Breaker Ensures Global Electrical Safety

BYQ5 ATS Isolation Dual Power Automatic Transfer Switch

BY19G 63A Manual Changeover Switch: Features and Benefits

Support

Blog

Contact Us

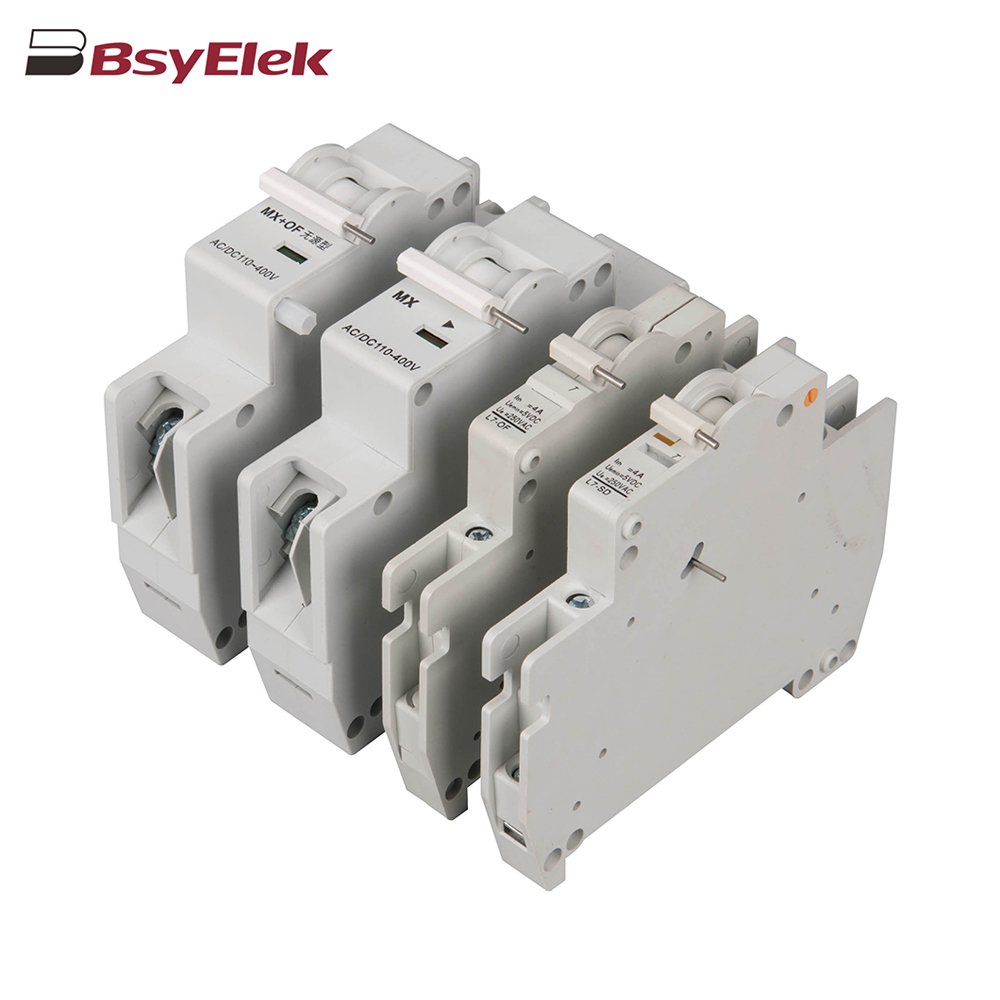

OF SD MX OF MCB Miniature Circuit Breaker Accessories

OF SD MX OF MCB Miniature Circuit Breaker Accessories BYG1-125 Main Switch MCB Isolator Switch

BYG1-125 Main Switch MCB Isolator Switch BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector

BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector

BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector BYX2 6-95A AC Contactor

BYX2 6-95A AC Contactor BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device

BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device

BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device

BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device BY19G 63A Manual Changeover Switch

BY19G 63A Manual Changeover Switch LWSF-125 125A Manual Changeover Switch

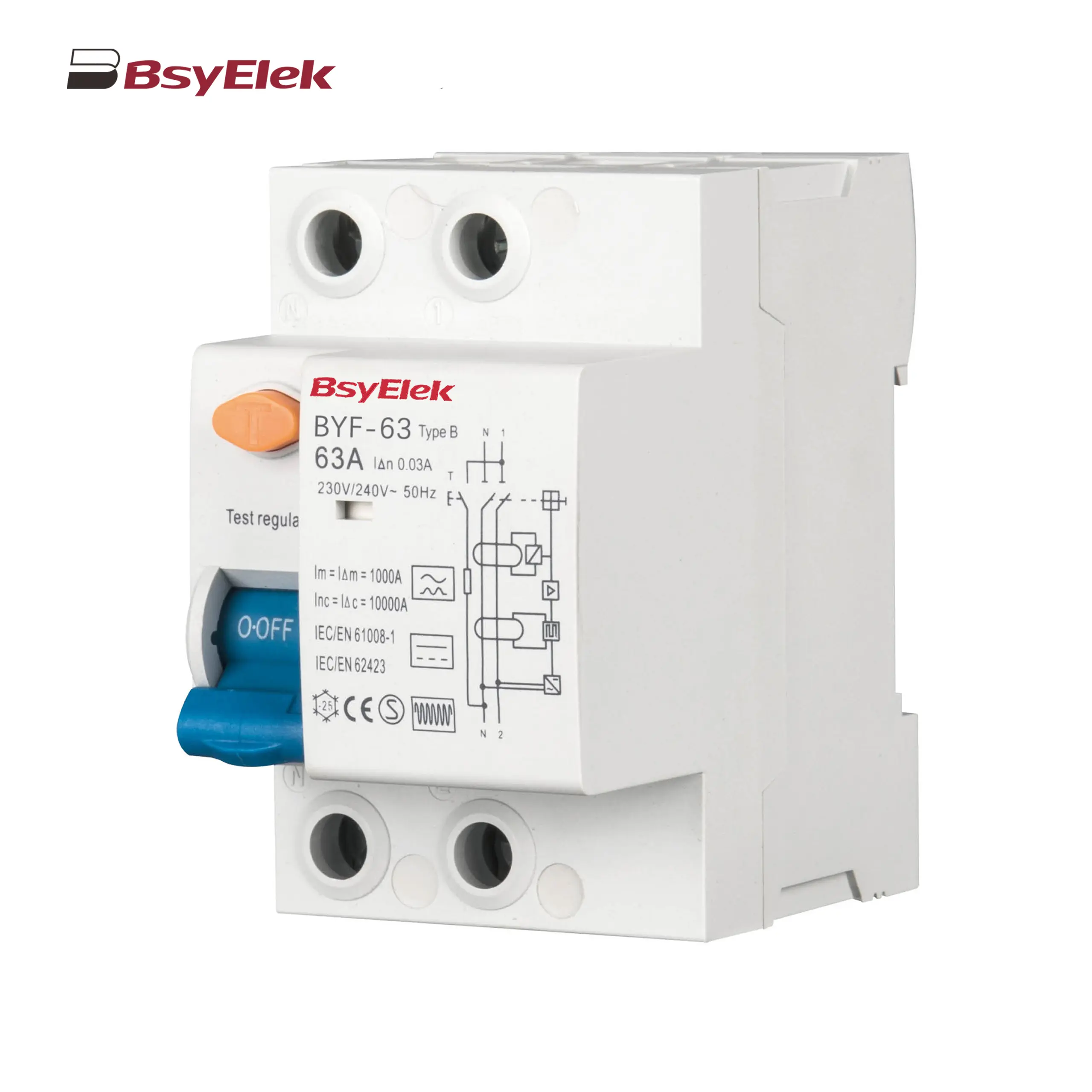

LWSF-125 125A Manual Changeover Switch BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device

BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device

BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device

BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link

BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link

BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link BYPV-ELR2 PV Isolator Switch with Enclosed Version

BYPV-ELR2 PV Isolator Switch with Enclosed Version BYPV-ELR1 PV Isolator Switch with Enclosed Version

BYPV-ELR1 PV Isolator Switch with Enclosed Version BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle

BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle BYPV-NL1 PV Isolator Switch with Lever Handle

BYPV-NL1 PV Isolator Switch with Lever Handle BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle

BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle PV-BY-01 30A/50A 1000V Photovoltaic Connector

PV-BY-01 30A/50A 1000V Photovoltaic Connector PV-BY-02 30A/50A 1500V Photovoltaic Connector

PV-BY-02 30A/50A 1500V Photovoltaic Connector PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector

PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector PV-BY-F01 30A 1500V Diode/Fuse Type Connector

PV-BY-F01 30A 1500V Diode/Fuse Type Connector PV-BY-T 50A 1500V T Type Branch Connector

PV-BY-T 50A 1500V T Type Branch Connector PV-BY-Y 30A 1500V Y Type Branch Connector

PV-BY-Y 30A 1500V Y Type Branch Connector PG Waterproof Cable Gland with Washer

PG Waterproof Cable Gland with Washer Photovoltaic Cable

Photovoltaic Cable HD11N Photovoltaic Knife Switch

HD11N Photovoltaic Knife Switch BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker

BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker

BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker BYM1E MCCB Electronic Type Molded Case Circuit Breaker

BYM1E MCCB Electronic Type Molded Case Circuit Breaker BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker

BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker BYW1 ACB Intelligent Universal Air Circuit Breaker

BYW1 ACB Intelligent Universal Air Circuit Breaker BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch

BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch Stainless Steel Hinge Type Electrical Box

Stainless Steel Hinge Type Electrical Box HA Waterproof Distribution Box

HA Waterproof Distribution Box HT Waterproof Distribution Box

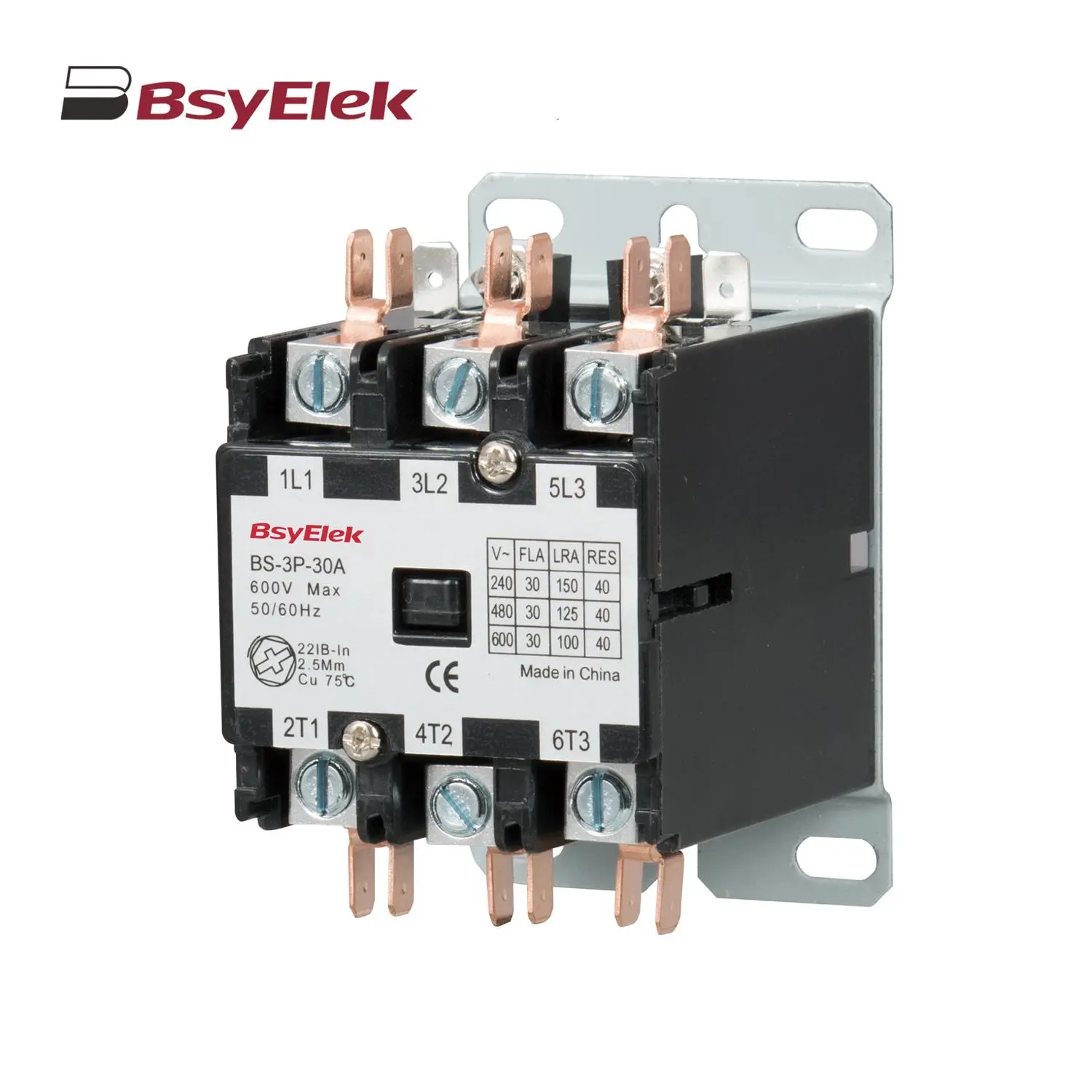

HT Waterproof Distribution Box BS Definite Purpose Magnetic AC Contactor

BS Definite Purpose Magnetic AC Contactor